Coal mine fire prevention and extinguishing method using pit mouth power plant flue gas

A technology for pit-head power plants and fire prevention, which is applied in the fields of fire prevention, dust prevention, mining equipment, etc., can solve the problems of energy consumption and high nitrogen production cost, and achieve the effect of saving energy waste, low cost and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

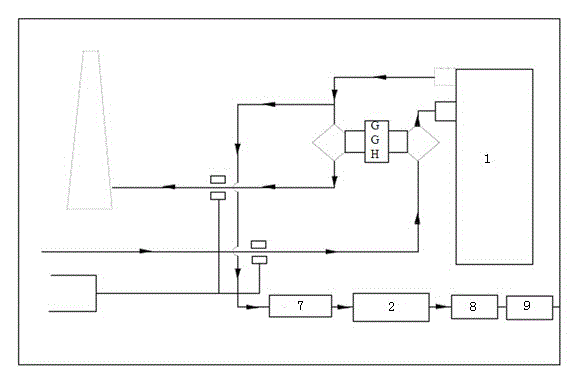

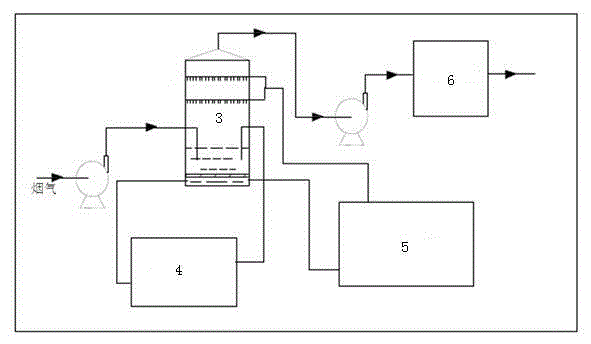

[0014] The coal mine fire prevention and extinguishing method utilizing pit mouth power plant flue gas of the present invention, as figure 1 As shown, the flue gas is taken from the outlet of the desulfurization tower 1 of the coal mine pit mouth power plant. The flue gas passes through the flue gas pretreatment system 2 for denitration, dehumidification, cooling, and dust removal. The system is pressurized to inject flue gas downhole. Since the flue gas directly discharged from the power plant contains some harmful pollutants, in order to ensure the safety of the flue gas injection downhole and the safety of pipeline transportation, this part of the flue gas injected into the downhole needs denitrification, dehumidification, cooling, and dust removal to achieve flue gas injection. condition. The pretreated flue gas needs to be transported underground through pressurized pipelines.

[0015] Take Tashan Coal Mine of Tongmei Group Datang as an example below to describe the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com