Overload protection debugging control method, overload protection debugging control device, overload protection debugging control system and engineering machine

A technology of overload protection and construction machinery, applied in the field of debugging and control of overload protection, can solve problems such as low accuracy, hidden dangers, and increased engine power, and achieve the effects of improving accuracy, improving service life, and reducing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

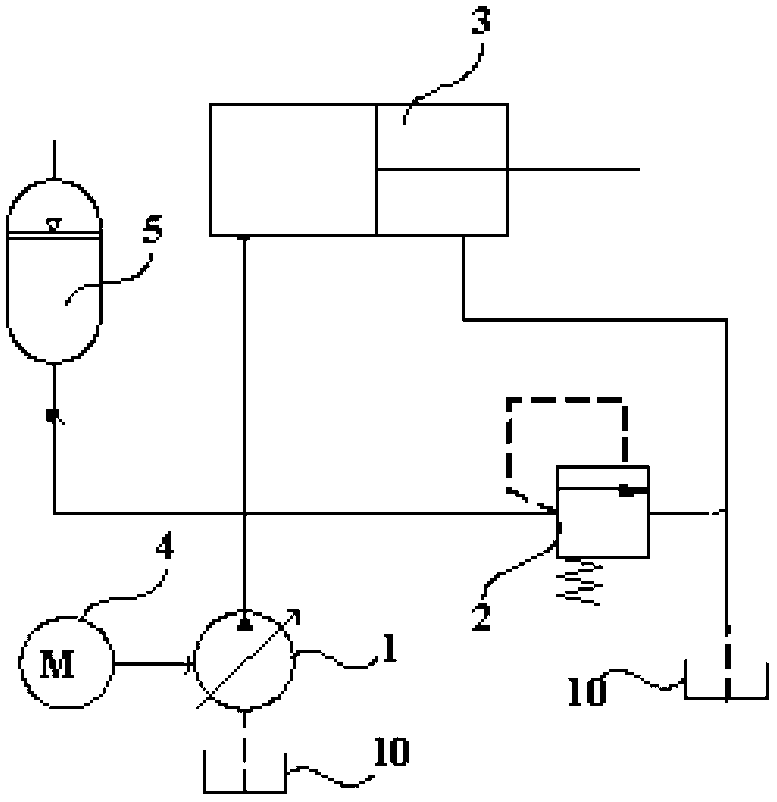

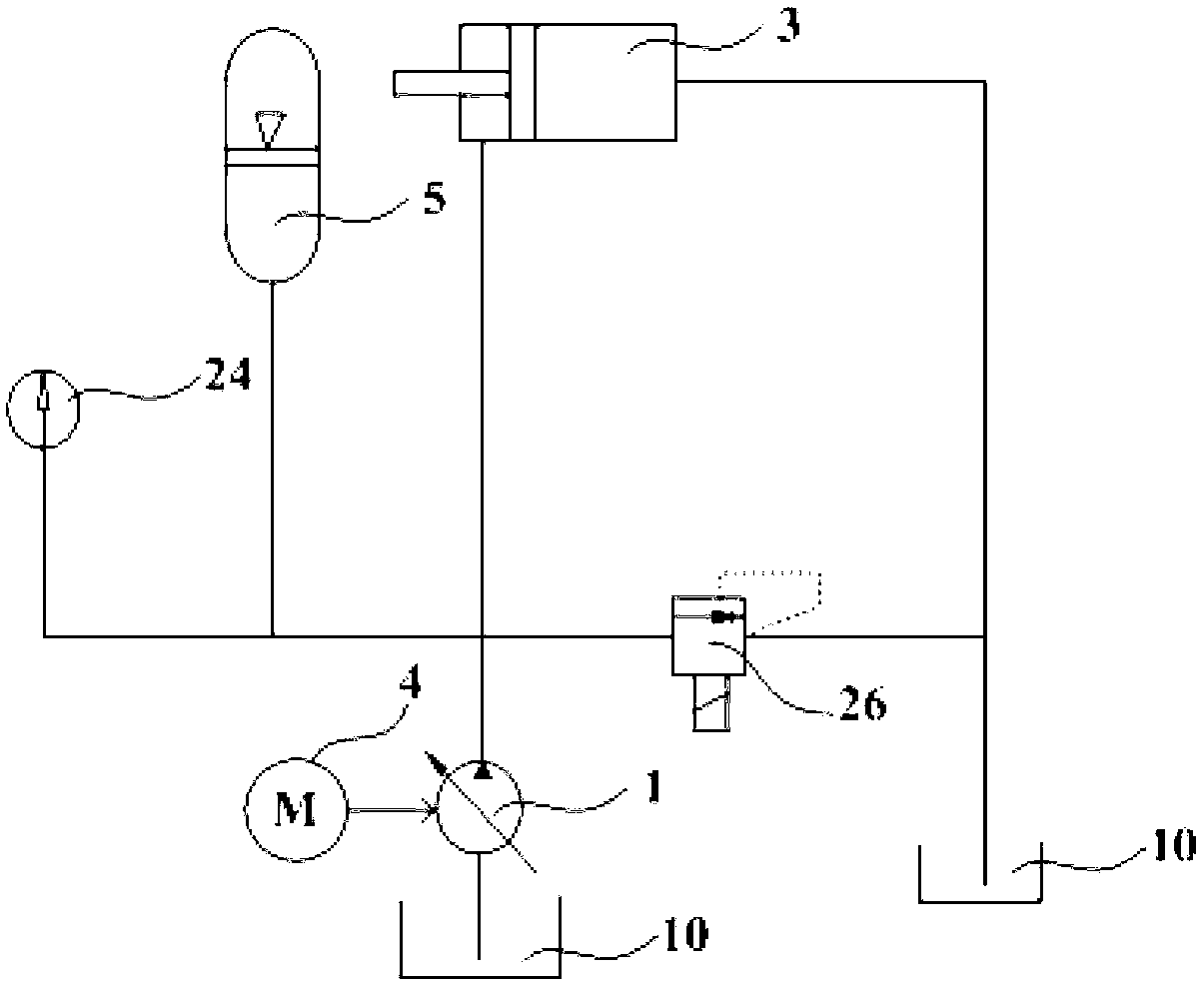

[0037] In order to improve the calibration accuracy of the overflow valve setting pressure and reduce unnecessary energy waste in the hydraulic constant pressure system, the embodiments of the present invention provide a debugging control method, device, system and construction machinery for overload protection. In this technical solution, the pressure of the hydraulic constant pressure system does not need manual visual inspection, and the adjustment of the electric proportional relief valve is completed through electronic control, and the commissioning personnel only need to manually input the opening adjustment information of the electric proportional relief valve. Therefore, The accuracy of pressure calibration of relief valve setting is greatly improved. The present invention will be described in detail below with specific embodiments and in conjunction with the accompanying drawings.

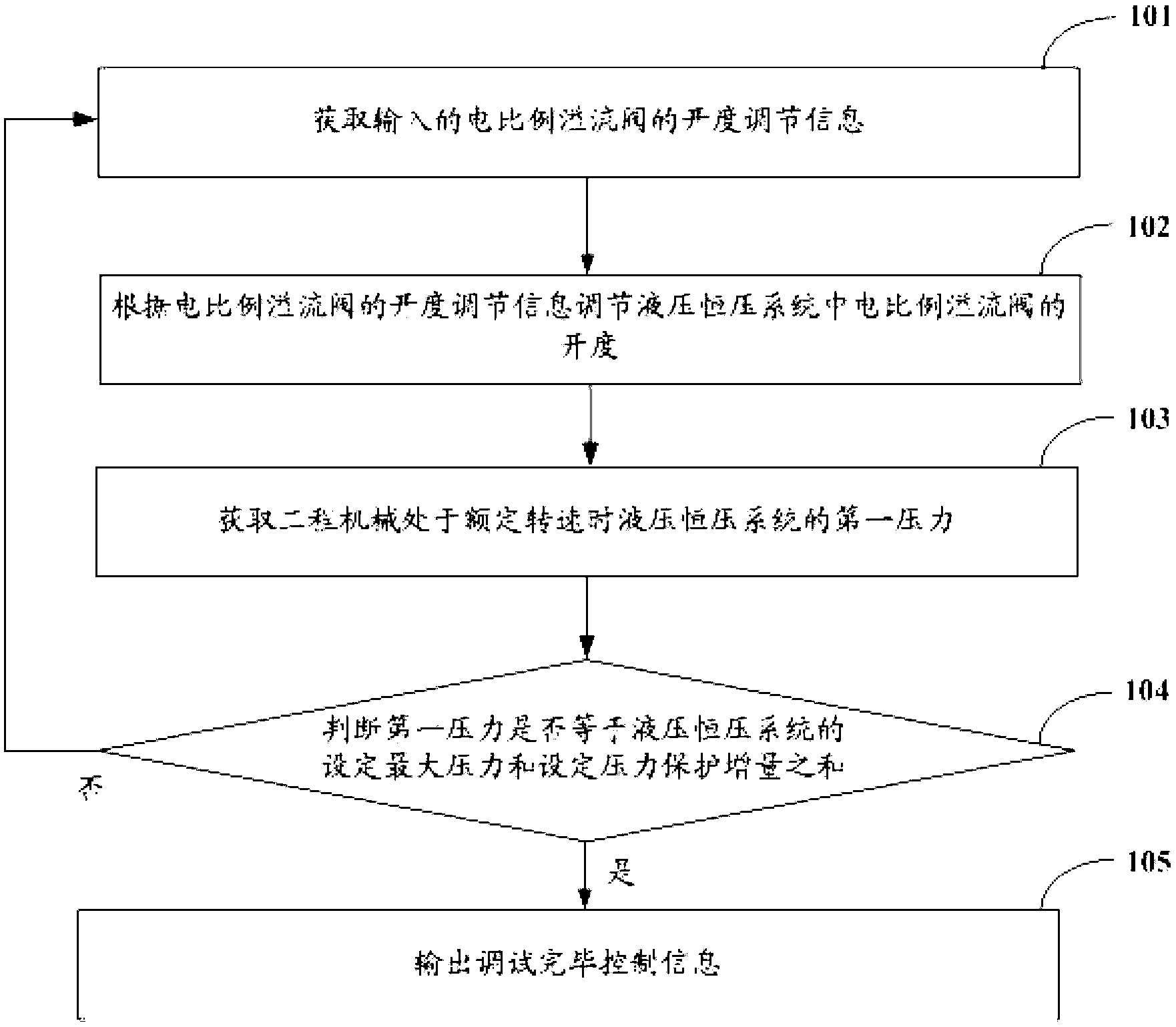

[0038] Such as figure 2 In the illustrated embodiment, the debugging control method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com