One-chip latch type Hall sensor

A Hall sensor, single-chip technology, applied in the field of single-chip latch Hall sensors, can solve the problems of Hall plate sensitivity reduction, affecting signal establishment accuracy, sampling signal establishment accuracy deviation, etc., to achieve sensitivity temperature The drift effect is reduced and the effect of avoiding the charge injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] According to the accompanying drawings, preferred embodiments and alternative embodiments of the present invention are given below, and described in detail, so as to better understand the functions and characteristics of the present invention.

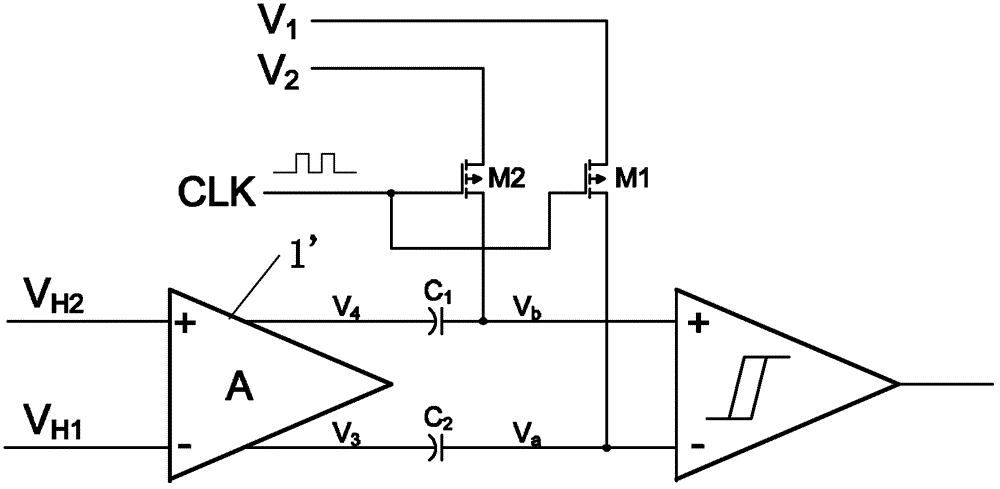

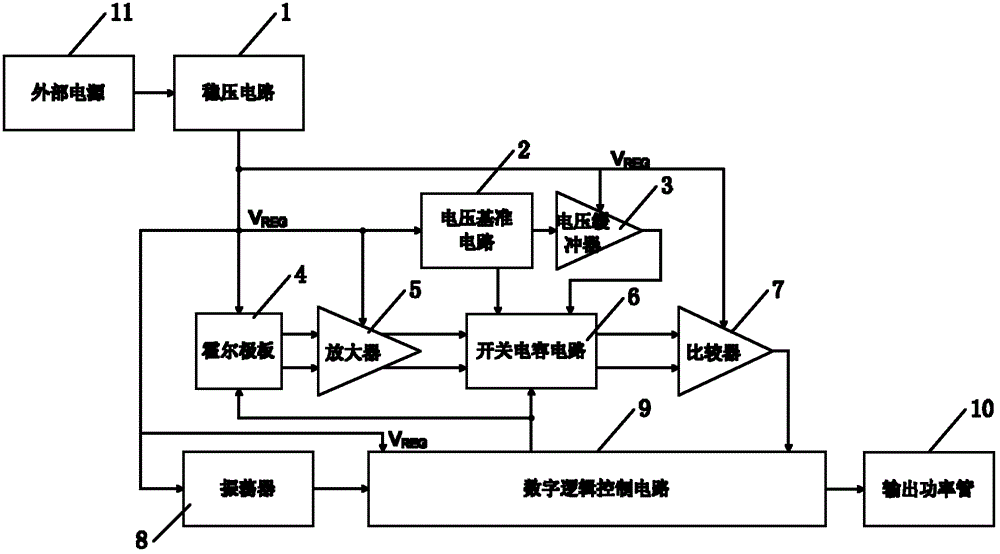

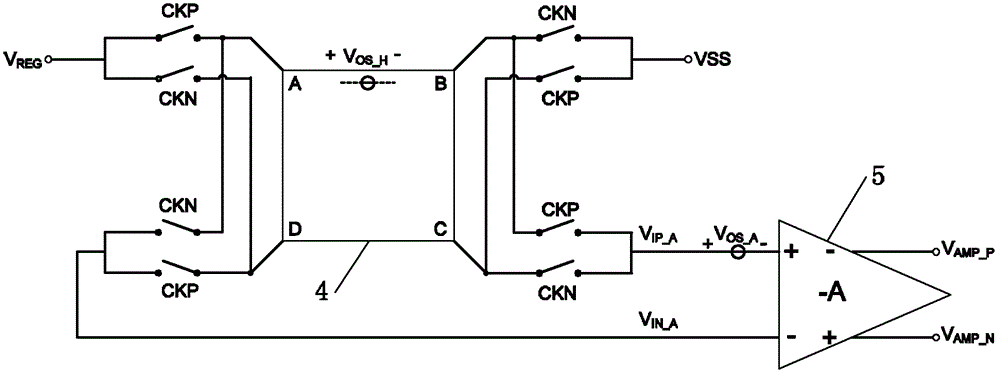

[0034] Such as figure 2 As shown, the present invention, that is, a single-chip latch-type Hall sensor, includes a voltage stabilizing circuit 1, a voltage reference circuit 2, a voltage buffer 3, a Hall plate 4, an amplifier 5, a switched capacitor circuit 6, and a comparison Device 7, oscillator 8, digital logic control circuit 9 and output power tube 10.

[0035] The voltage stabilizing circuit 1 is used to convert the voltage of the external power supply 11 into the internal power supply V REGvoltage, and supply power to voltage reference circuit 2, voltage buffer 3, Hall plate 4, amplifier 5, comparator 7, oscillator 8 and digital logic control circuit 9 respectively, the internal power supply V REG The voltage is not af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com