Method for measuring misch metal solid solubility in steel and iron materials

A technology of iron and steel materials and mixed rare earths, applied in the field of physical and chemical testing, can solve the problems of dangerous experimental process, poor sensitivity, high subtraction, etc., and achieve the effect of safe experimental process, good universality and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

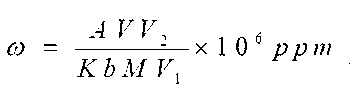

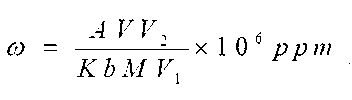

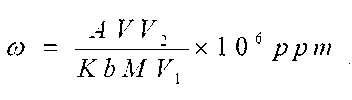

Image

Examples

Embodiment Construction

[0025] The specific steps are:

[0026] (1) Electrolysis: The proportion by weight of the electrolyte is: 2% LiCl, 2% TEA triethanolamine, 0.5% ethylene glycol, 0.2% diphenylguanidine, 1.5% benzene, and the balance is anhydrous ethanol;

[0027] During electrolysis, the anode is an electrolysis sample of iron and steel material mixed with rare earths, and the cathode is a stainless steel tube; the sample is weighed and recorded before electrolysis, and the electrolysis temperature is -10°C. After 2-3 hours of electrolysis, turn off the power, take out the sample, and Weigh after drying, and the change in weight before and after is the mass M consumed by the sample; during electrolysis, the contact between the anode iron clip and the sample cannot be immersed in the electrolyte.

[0028] (2) Separation of solid solution rare earth and rare earth second phase inclusions: put 4-6 layers of slow-speed quantitative filter paper in the Buchner funnel, pour the electrolyzed electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com