Lithium ion battery activation method

A lithium-ion battery and activation method technology, which is applied in the field of lithium-ion battery activation, can solve the problems of battery performance deterioration, safety hazards of positive and negative short circuits, and consumption of electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

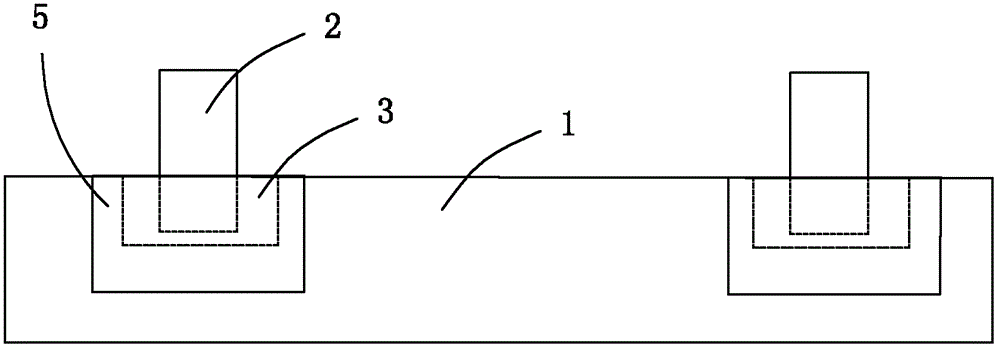

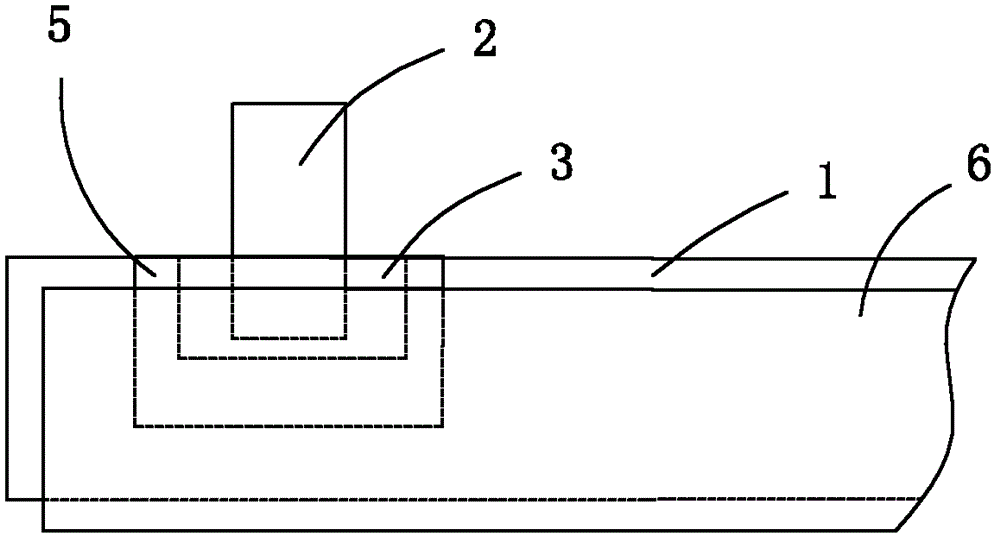

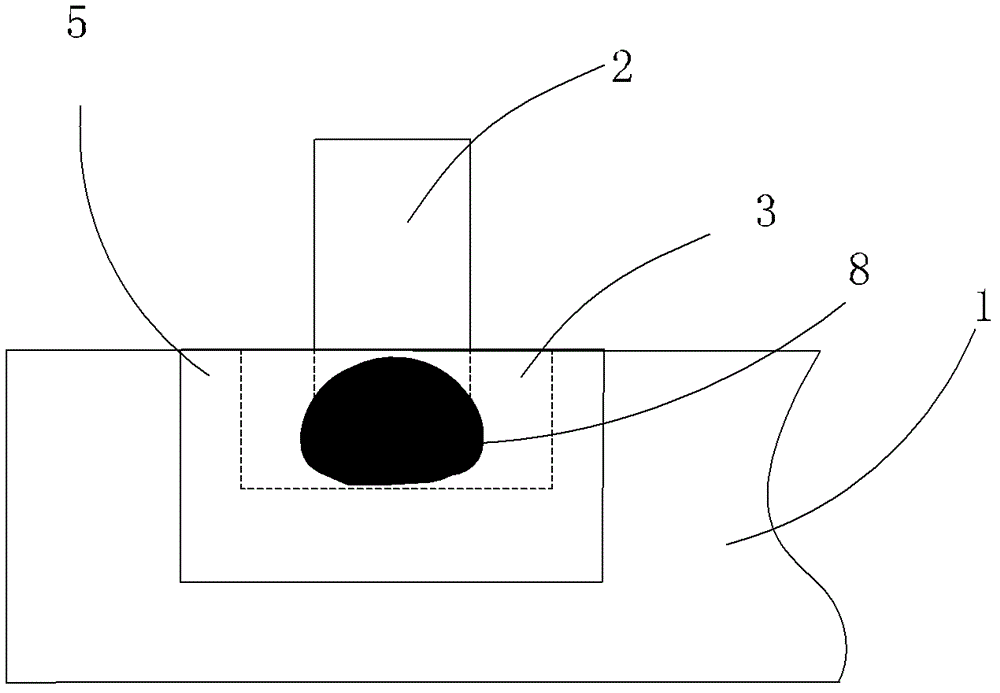

Image

Examples

Embodiment 1

[0055] The lithium ion battery activation method of one embodiment, comprises the following steps:

[0056] Step S21 , constant current charging stage, the constant current charging current is 0.02CA, and the charging time is 3h.

[0057] Step S22 , constant current and constant voltage charging stage, the constant current charging current is 0.1CA, the constant current charging is until the voltage is 3.6V, and then the constant voltage is 3.6V charging until the current is 0.01CA. In this embodiment, the lithium ion battery is a lithium iron phosphate battery.

[0058] Step S23 , constant current discharge stage, the constant current discharge current is 0.05CA, and the discharge time is 4h.

[0059] Step S24 , constant current and constant voltage charging stage, the constant current charging current is 0.05C A, the constant current charging is until the voltage is 3.6V, and then the constant voltage 3.6V charging is until the current is 0.01C A.

[0060] Step S25 , const...

Embodiment 2

[0064] The lithium ion battery activation method of one embodiment, comprises the following steps:

[0065] Step S31 , constant current charging stage, the constant current charging current is 0.1C A, and the charging time is 1.5h.

[0066] Step S32 , constant current and constant voltage charging stage, the constant current charging current is 0.3CA, the constant current charging is until the voltage is 4.2V, and then the constant voltage is 4.2V charging until the current is 0.05CA. In this embodiment, the lithium ion battery is a lithium cobaltate-lithium manganate-lithium nickelate ternary lithium battery.

[0067] Step S33 , constant current discharge stage, the constant current discharge current is 0.2CA, and the discharge time is 1h.

[0068] Step S34 , constant current and constant voltage charging stage, the current of constant current charging is 0.2CA, the constant current charging is until the voltage is 4.2V, and then the constant voltage 4.2V charging is ended u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com