Lithium battery negative electrode material, and preparation method of lithium battery applying lithium battery negative electrode material

A negative electrode material, lithium battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of unstable peel strength, lithium precipitation, etc., to avoid lithium precipitation problems, optimize battery performance, and improve negative electrode capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

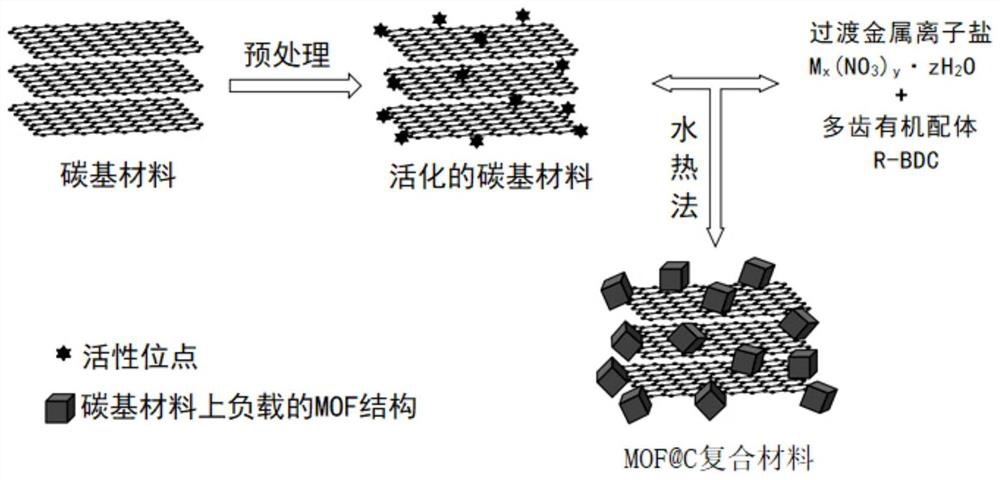

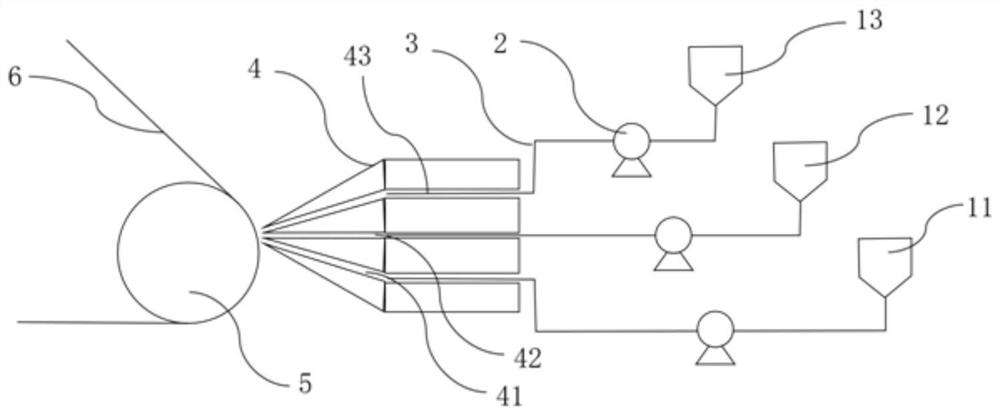

[0032] See figure 1 , a preparation method of a lithium battery negative electrode material, comprising the following steps:

[0033] (1) Pretreatment of carbon-based materials: soak carbon-based materials in acetone for 3 hours at room temperature, filter and wash with deionized water for 5 times, dry at 60°C in an inert gas, and then put them in an oxidant Reflux, control the reflux temperature at 60°C; take out the carbon-based material after 3 hours, wash the carbon-based material with 0.1mol / L hydrochloric acid until neutral, and finally fully dry it in a vacuum oven at 80°C to obtain activated carbon-based Material;

[0034] (2), the activated carbon-based material prepared in step (1) together with the transition metal ion salt Zn(NO 3 ) 2 ·6H 2O. The multidentate organic ligand HBDC is added to N,N-dimethylformamide DMF that has been dehydrated by molecular sieves and mixed evenly, and then 99.999% high-purity argon gas is introduced at a speed of 0.5L / min for 3 ho...

Embodiment 2

[0041] A kind of preparation method of lithium battery negative electrode material is consistent with embodiment 1, just the transition metal ion salt Zn(NO in step (2) 3 ) 2 ·6H 2 Replace O with Cu(NO 3 ) 2 ·6H 2 O, Cu-MOF@C composites were finally prepared.

[0042] The method for preparing the lithium battery from the negative electrode material of the lithium battery is completely consistent with that in Example 1.

Embodiment 3

[0044] A kind of preparation method of negative electrode material of lithium battery and the preparation method of lithium battery are completely consistent with embodiment 1, just in step (c), negative pole piece is 30g·m together with areal density -2 , The compacted density is 3.5g·cm -3 The NCM811 ternary material positive pole piece, PP dry-process separator and electrolyte complete the assembly of the square shell lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com