Plasma laser device

A plasma and laser technology, which is applied to the structure of optical waveguide semiconductors, can solve problems such as unfavorable miniaturization of devices, unfavorable laser devices, and large volume, and achieve the effects of being conducive to miniaturization, strong binding ability, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

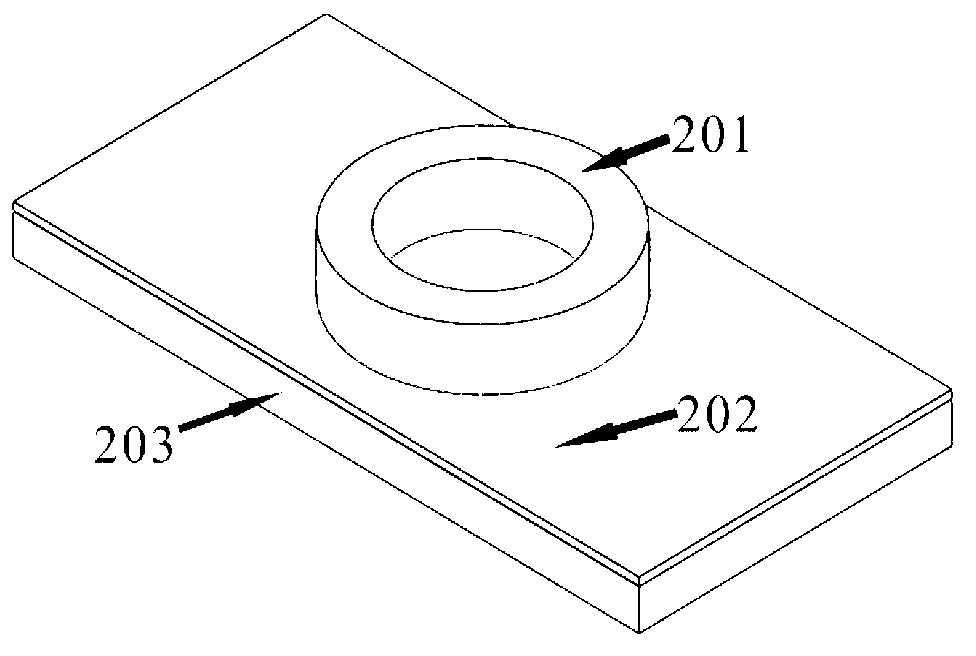

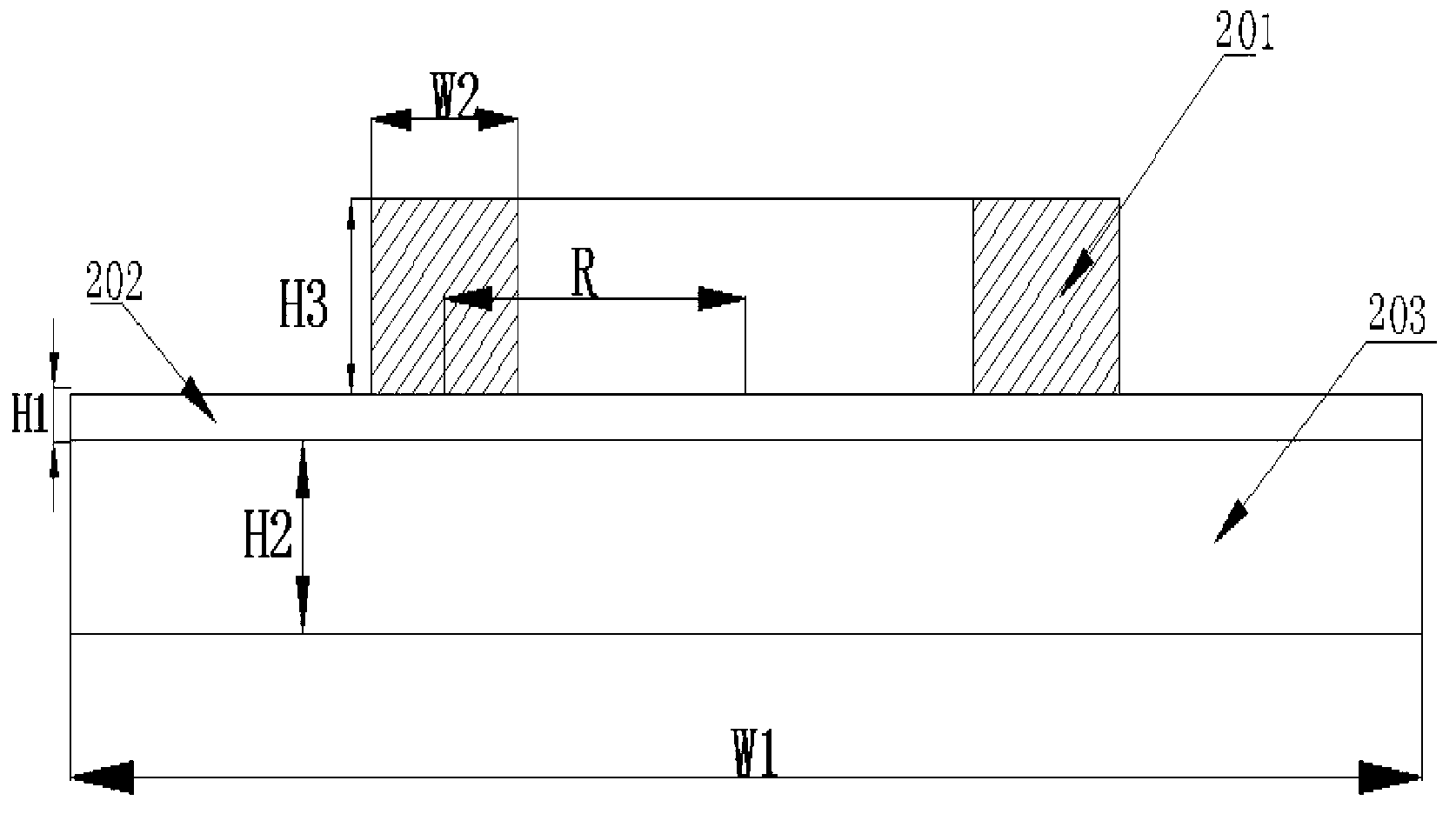

[0039] Please refer to figure 2 , a plasma laser provided in an embodiment of the present application, including a metal layer 203, a low-refractive-index medium layer 202 formed on the metal layer 203, and a ring-shaped gain medium layer formed on the low-refractive-index medium layer 202 201 , the cross section of the gain medium layer 201 closest to the metal layer 203 falls within the range covered by the metal layer 203 . In other embodiments, the low-refractive-index medium layer 202 may not be included, but only the double-layer structure of the metal layer 203 and the annular gain medium layer 201 .

[0040] The cross-sectional shape of the gain medium layer 201 is a rectangle, and may be any one of an oval ring, a hexagonal ring, a square ring, a trapezoidal ring, and a triangular ring. The ring-shaped gain medium layer 201 formed in this example reduces the contact surface with the low-refractive index medium layer, thereby reducing metal loss. At this time, light...

Embodiment 2

[0052] Such as Figure 7 As shown, another structural plasmonic laser of the present application includes a gain medium layer 301 and a metal layer 302, wherein the cross section of the gain medium layer 301 parallel to the metal layer 302 is an elliptical ring structure.

[0053] Due to the effect of surface plasmons, the optical field is limited to the contact surface of the metal layer 301 and the gain medium layer 302. At the same time, since the contact surface of the metal layer 301 and the gain medium layer 302 is annular, that is, the contact surface is very small, thereby reducing the The loss to the metal is reduced, and the light circulates along the annular contact surface, which can also produce a good coupling effect.

[0054] In another embodiment, a low-refractive index medium layer may also be formed between the gain medium layer 301 and the metal layer 302, and the cross section of the gain medium layer 301 closest to the metal layer 302 falls within the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com