Stair-stepping tea continuous-fermentation device

A fermentation device and step-by-step technology, applied in the direction of tea treatment before extraction, can solve the problems of fermented leaves being greatly affected by the environment, affected by climate change, and poor hygienic conditions, so as to ensure uniformity and consistency, and the quality of consistency is obvious , The effect of improving consistency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

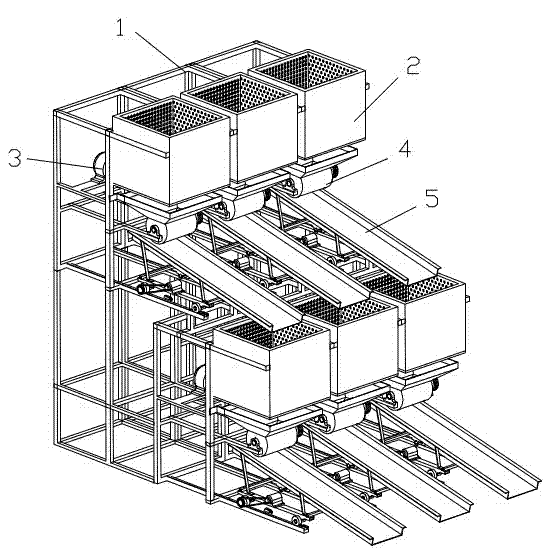

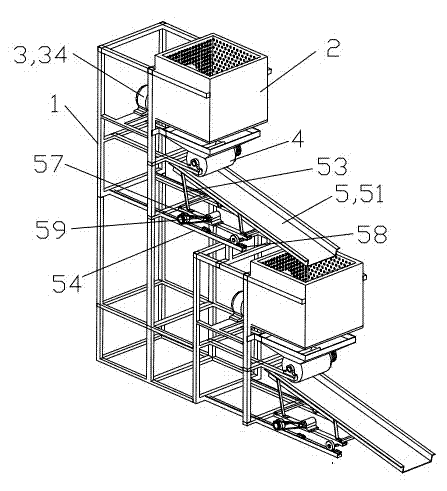

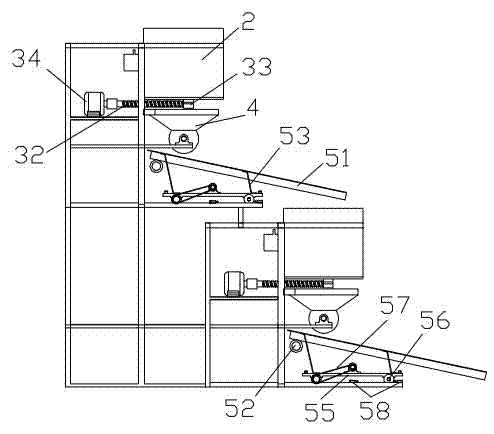

[0028] see Figure 1 ~ Figure 4 , a kind of step-type continuous fermentation device for tea in a preferred embodiment of the present invention comprises a frame 1 and two fermentation units arranged on the frame 1 in steps up and down. The two fermentation units are connected in series up and down to form a fermentation group. In this embodiment, the fermentation device includes three fermentation groups and six fermentation units.

[0029]The fermentation unit includes a fermentation tank 2 , a discharge device 3 , a breaking device 4 and a conveying device 5 . The fermentation box 2 includes a main body of the fermentation box surrounded by four outer plates 21 , and is surrounded by four inner orifice plates 22 in the fermentation box 2 and is spaced from the outer plates 21 to form an annular air chamber 223 . The upper and lower ends of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com