Two-stage biological desulfuration device of marsh gas

A biological desulfurization, two-stage technology, applied in the fields of gas fuel, air quality improvement, petroleum industry, etc., can solve the problems of increasing the pressure drop of biogas in the desulfurization tower, affecting the desulfurization effect, and SO42-accumulation, etc., to avoid unsafe factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

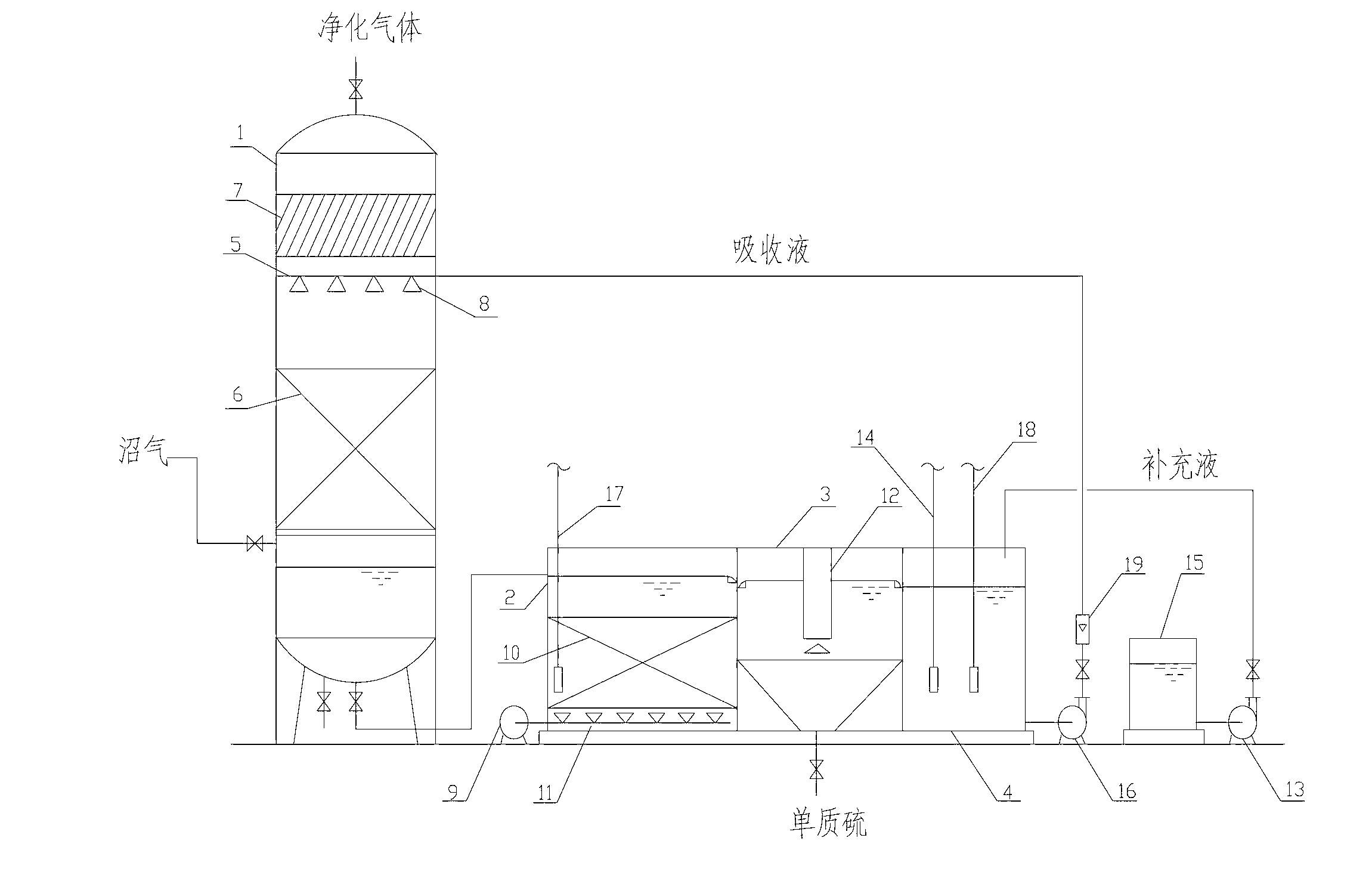

[0023] As shown in Figure 1, the device in this embodiment includes an absorption tower 1 for removing hydrogen sulfide, a water distributor 5, an oxidation tank 2, a sedimentation tank 3, a clear liquid tank 4, an air pump 9, a dosing pump 13, and an automatic heater 14 etc.; the bottom of the absorption tower 1 is connected to the bottom of the oxidation tank 2 through pipelines; the top of the absorption tower 1 is connected to the bottom of the clear liquid tank 4 through a circulating pump 16 and pipelines; the absorption tower 1 is provided with a packing layer 6, and the bottom of the packing layer 6 is provided There are biogas inlets, liquid outlets and sewage outlets, and a gas outlet and a water distributor 5 are arranged above the packing layer 6 . A mist eliminator 7 is also provided in the absorption tower 1 between the packing layer 6 and the biogas outlet.

[0024] The above-mentioned oxidation tank 2, sedimentation tank 3 and clear liquid tank 4 are taken as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com