Electric power steering system

A technology of electric power steering and steering column, which is applied to electric steering mechanism, automatic steering control components, steering mechanism and other directions to achieve the effect of simple control method, low cost and little interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

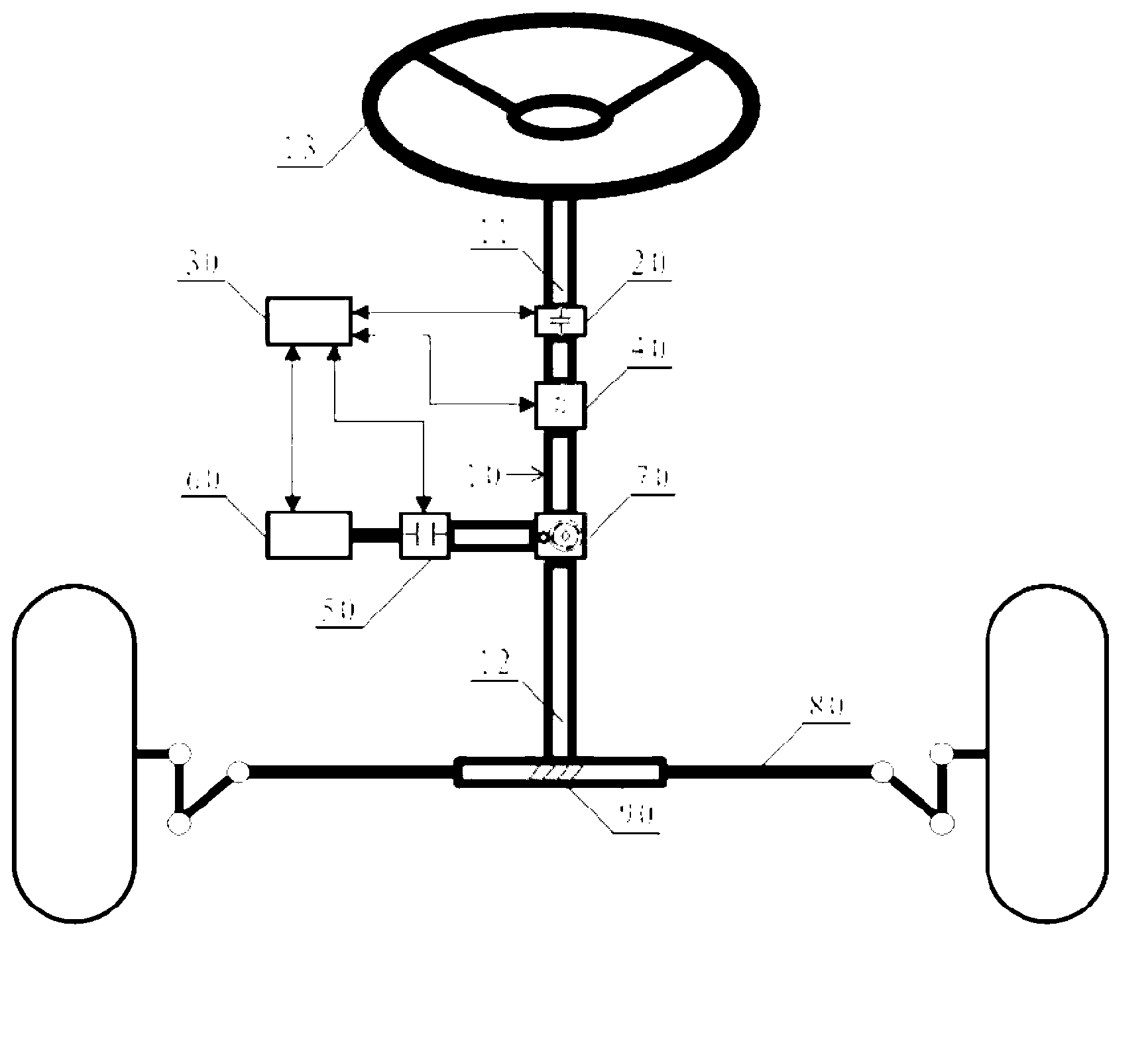

[0007] combine figure 1 The electric power steering system includes a steering wheel 13 and an upper main shaft 11 coaxially connected with the steering wheel 13. The upper and lower main shafts 11, 12 are supported and rotated by the steering column 10. The first electromagnetic clutch 20 is connected to the upper and lower shafts in the steering column 10. Between the lower main shafts 11 and 12, the first electromagnetic clutch 20 receives the control signal output by the electric power steering system controller 30 and engages. When the first electromagnetic clutch 20 is engaged, the upper and lower main shafts 11 and 12 synchronize the shafts; the steering column A torque sensor 40 is arranged between 10 and the upper main shaft 11; the electric power steering system controller 30 outputs a control signal to the power assist mechanism to drive the lower main shaft 12 in the steering column 10 to rotate. The engaging state of the above-mentioned first electromagnetic clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com