Production method of inkjet ceramic plate for dry-hanging building curtain wall

A production method and construction technology, applied in the field of ceramic plate production technology, can solve the problems of dry and dull patterns, and the green body is not easy to absorb ink, and achieve the effects of clear graphics, saving high-quality clay resources, and realistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

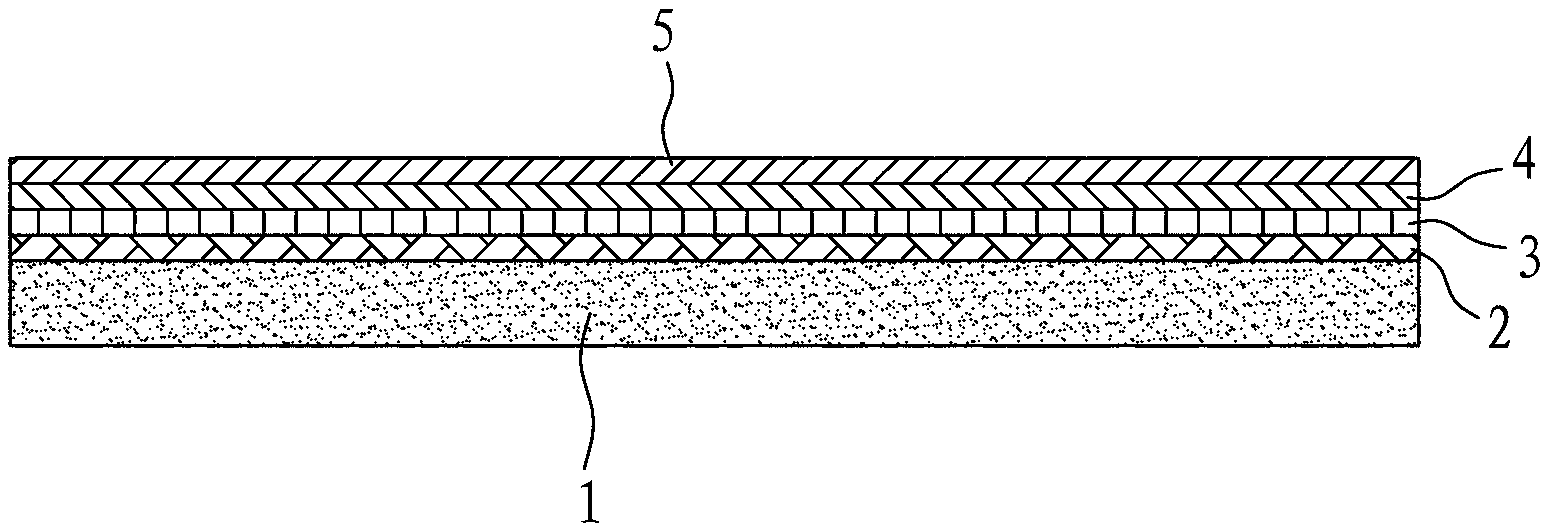

Image

Examples

Embodiment

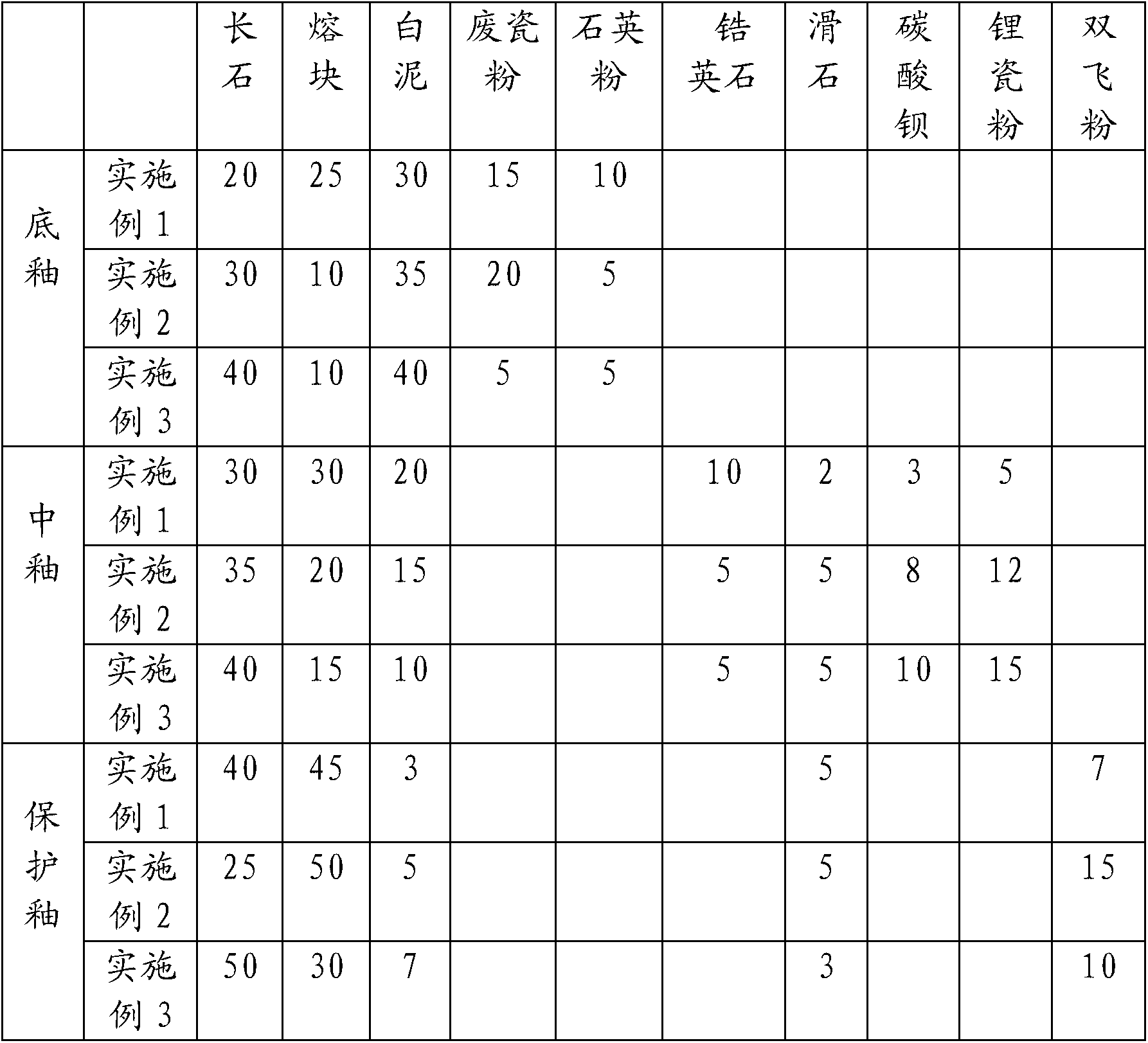

[0054] Raw material used among the present invention and bottom glaze, medium glaze, the weight ratio of protective glaze is shown in table 1 embodiment.

[0055] Table 1:

[0056]

[0057] The above numerical values all refer to weight percent wt%.

[0058] The various embodiments of the bottom glaze, the middle glaze and the protective glaze can be combined arbitrarily, and the implementation steps are as follows:

[0059] 1. First prepare the bottom glaze, the middle glaze and the protective glaze according to the formula in each embodiment in Table 1, then add 0.3-0.5% sodium tripolyphosphate and 0.15-0.3% carboxymethyl cellulose respectively, and then According to the ratio of material: water = 1:0.8, add water and ball mill to a suitable fineness, usually controlled at 0.3-0.5% of the million-hole sieve.

[0060] 2. Apply a layer of bottom glaze to the prepared ceramic plate body, the specific gravity of the bottom glaze is controlled between 1.6-1.7, and the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com