Method for preparing lauric acid monoglyceride by immobilized lipase

A technology of monolauric acid monoglycerol and immobilized lipase, which is applied in the field of preparation of monolauric acid monoglyceride, can solve the problems of large acid-base salt discharge, non-recyclable, harsh reaction conditions, etc., and achieve resource and cost saving, The effect of low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

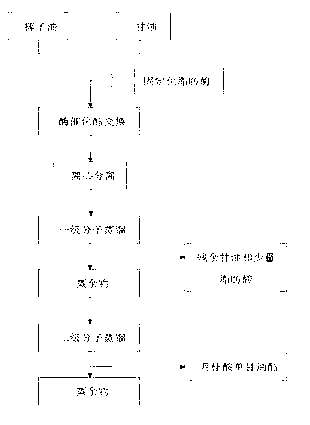

Method used

Image

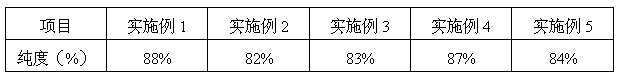

Examples

Embodiment 1

[0024] (1) transesterification

[0025] Add 55.7 grams of coconut oil and 29.1 grams of glycerin into a 150mL flat-bottomed flask (the molar ratio of the two is 1:3, and the water content of glycerin is 4%). After the temperature (50°C), add 4.456g Novozym 435 immobilized lipase (Novozymes) (the amount added is 8% of the weight of the above coconut oil), stir constantly, and continue to place it in the above constant temperature water bath for transesterification Reaction, time 36h.

[0026] (2) centrifugal

[0027] The transesterification product obtained in step (1) is placed in a centrifuge with a centrifugal force of 5000g to separate the immobilized lipase and unreacted glycerin, and the upper oil phase is taken as a mixture of fatty acid glycerides.

[0028] (3) Primary molecular distillation

[0029] The fatty acid glyceride mixture obtained in step (2) is subjected to primary molecular distillation using a scraped-film short-range molecular distillation apparatus (p...

Embodiment 2

[0033] (1) transesterification

[0034] Add 55.7 grams of coconut oil and 38.8 grams of glycerin into a 150mL flat-bottomed flask (the molar ratio of the two is 1:4, and the water content of glycerin is 5%). After the temperature (40°C), add 3.342g Lipozyme TL IM immobilized lipase (same as above) (the amount added is 6% of the weight of the above coconut oil), stir constantly, and continue to place it in the above constant temperature water bath for the transesterification reaction. Time 24h.

[0035] (2) centrifugal

[0036] The transesterification product obtained in step (1) is placed in a centrifuge with a centrifugal force of 5500g to separate the immobilized lipase and unreacted glycerin, and the upper oil phase is taken as a mixture of fatty acid glycerides.

[0037] (3) Primary molecular distillation

[0038] The fatty acid glyceride mixture obtained in step (2) is subjected to primary molecular distillation using a wiped-film short-range molecular distillation app...

Embodiment 3

[0042] (1) transesterification

[0043] Add 55.7 grams of coconut oil and 38.8 grams of glycerin into a 150mL flat-bottomed flask (the molar ratio of the two is 1:4, and the water content of glycerin is 5%). After the temperature (40°C), add 2.785g Lipozyme RM IM immobilized lipase (same as above) (the amount added is 5% of the weight of the above coconut oil), stir constantly, and continue to place it in the above constant temperature water bath for the transesterification reaction. Time 48h.

[0044] (2) centrifugal

[0045] The transesterification product obtained in step (1) is placed in a centrifuge with a centrifugal force of 5000g to separate the immobilized lipase and unreacted glycerin, and the upper oil phase is taken as a mixture of fatty acid glycerides.

[0046] (3) Primary molecular distillation

[0047]The fatty acid glyceride mixture obtained in step (2) is subjected to primary molecular distillation using a wiped-film short-range molecular distillation appa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com