LED (Light Emitting Diode) ceramic substrate-based lamp and manufacturing method thereof

A technology of ceramic substrate and manufacturing method, which is applied in the direction of lampshade, parts of lighting device, lighting and heating equipment, etc., can solve the problems of inability to reflect out, overloaded chip heat dissipation, low reflection efficiency, etc., so as to improve the reflection efficiency and diffusion surface , the effect of changing the heat reflection effect, and the effect of enhancing the light penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

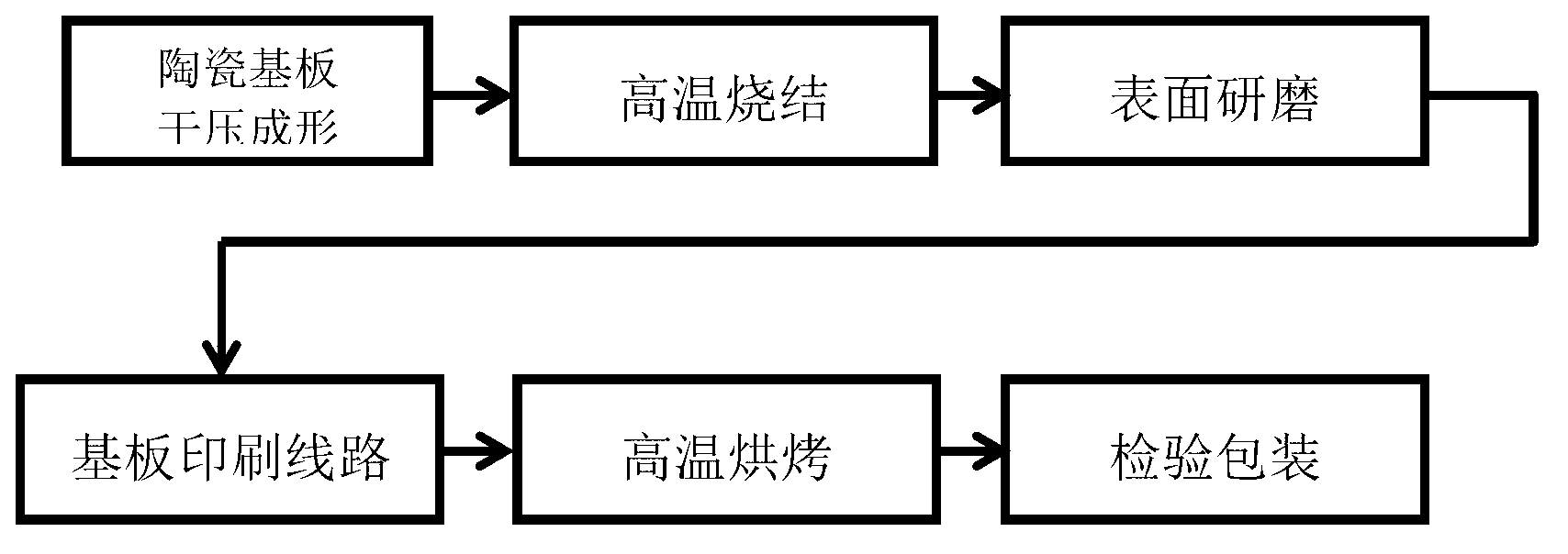

[0026] like figure 1 Shown, a kind of lamp manufacturing method based on LED ceramic substrate, comprises the following steps:

[0027] (1) Set up a pressing mold, use NPO ceramic powder to dry press the powder, and use the press to form a shaped ceramic body;

[0028] (2) Sinter the formed ceramic body in a vertical sintering furnace at 1300 degrees Celsius for 24 hours;

[0029] (3) Grinding the sintered ceramic body with a grinder to form a flat ceramic substrate;

[0030] (4) Design the circuit wiring diagram, and use the silver screen printing machine to screen-print the silver paste on the ceramic substrate;

[0031] (5) Lay silver foil at the welding point as a pad;

[0032] (6) Baking the silver-finished ceramic substrate in a tunnel furnace at a temperature of 800 degrees Celsius;

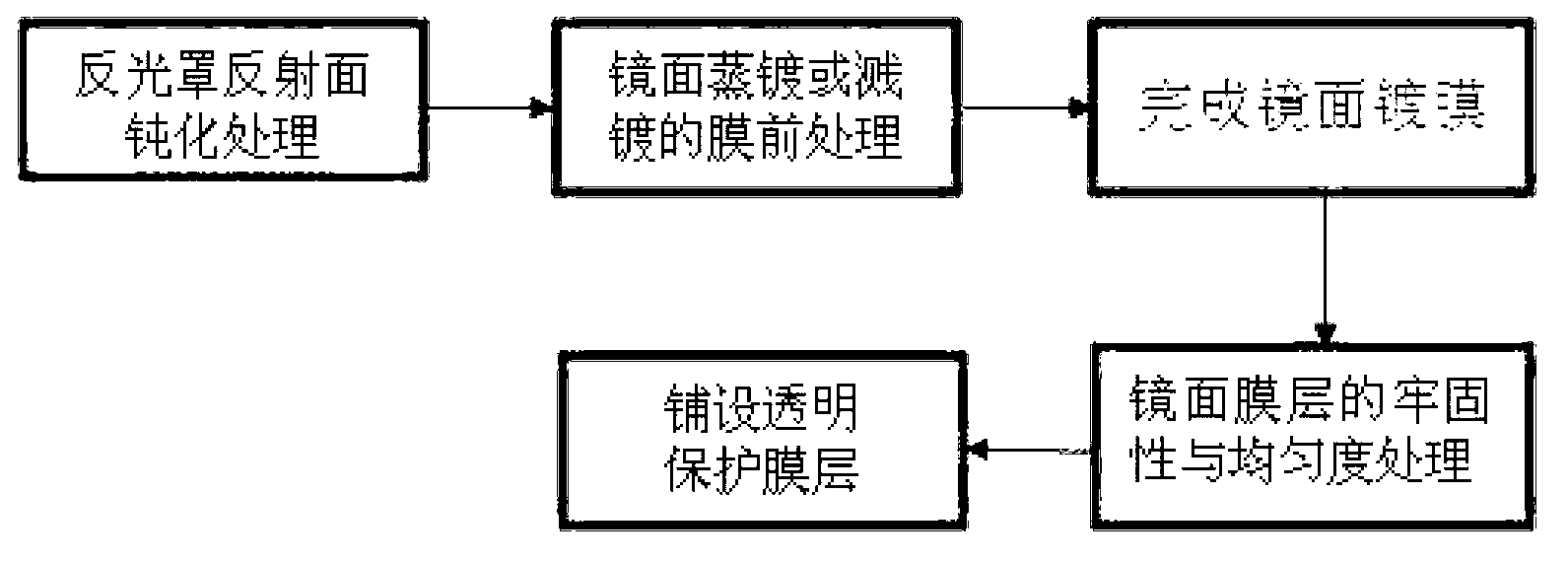

[0033] (7) Manufacture a reflector made of steel or aluminum. The reflective surface of the reflector is aluminum or silver. The surface of the base material of the reflective surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com