Method for measuring shape of material pile after material-taking in contact form

A contact measurement and stockpiling technology, which is applied in the field of stockpil shape measurement, can solve the problems of long measurement time, increase, and inability to increase the frequency of stockpil shape measurement, and achieve real-time measurement of stockpil shape, measurement accuracy assurance, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

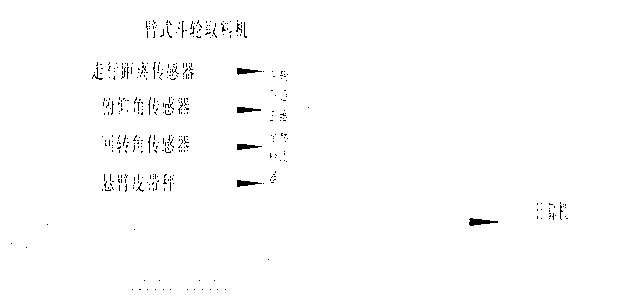

[0026] like figure 1 As shown, the system for measuring the shape of the material pile after reclaiming includes an arm-type bucket wheel reclaimer, a three-dimensional coordinate detector for the lower edge of the bucket wheel, a computer for processing the shape of the material pile, and a device on the arm-type bucket-wheel reclaimer There are bucket wheels for retrieving materials from the stockpile, travel distance sensors, pitch angle sensors, rotation angle sensors, and material flow detectors on cantilever belt conveyors or cantilever belt scales. The bucket wheels are fixed on the farthest end of the arm bucket wheel reclaimer. end, rotating around the central axis; the three-dimensional coordinate detector along the lower edge of the bucket wheel is installed on the arm-type bucket wheel reclaimer, and is connected with the travel distance sensor, pitch angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com