Deep and shallow sea alternating corrosion environment simulator

A technology for simulating devices and corrosive environments. It is used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc. It can solve the problems of accelerated coating aging, high test failure rate, material stress corrosion, etc., and achieve reliable operation and operation. Simple structure principle, real simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

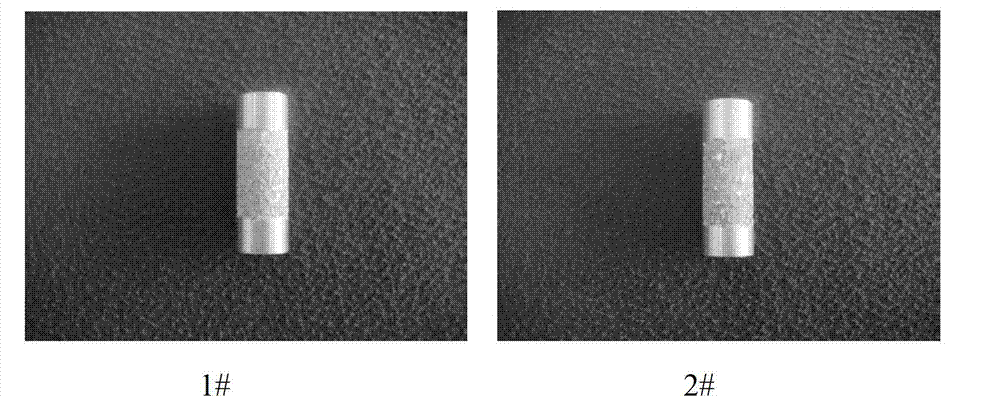

[0017] In this example, the electrochemical performance test of Al-Zn-In-Mg-Ti (No. 1) and Al-Zn-In-Mg-Ti-Ga-Mn (No. 2) was carried out according to the "Sacrificial Anode Electrochemical Performance Test" Method "GB / T 17848-1999, using the 4-day method test;

[0018] Test pressure: alternating between 3MPa and 4.5MPa, the relationship between the alternating time is as follows image 3 shown;

[0019] Test time: 96 hours;

[0020] Temperature: changes with pressure (simulated deep sea depth);

[0021] Dissolved oxygen: 4ppm;

[0022] Experimental results: as shown in Table 1 and Table 2;

[0023] Table 1 shows the open circuit potential and working potential:

[0024] Numbering

OCP / V

1d / V

2d / V

3d / V

4d / V

1#

-1.128

-1.062

-1.080

-1.004

-1.046

2#

-1.112

-1.067

-1.099

-1.077

-1.057

[0025] Table 2 shows the current efficiency:

[0026] Numbering

Embodiment 2

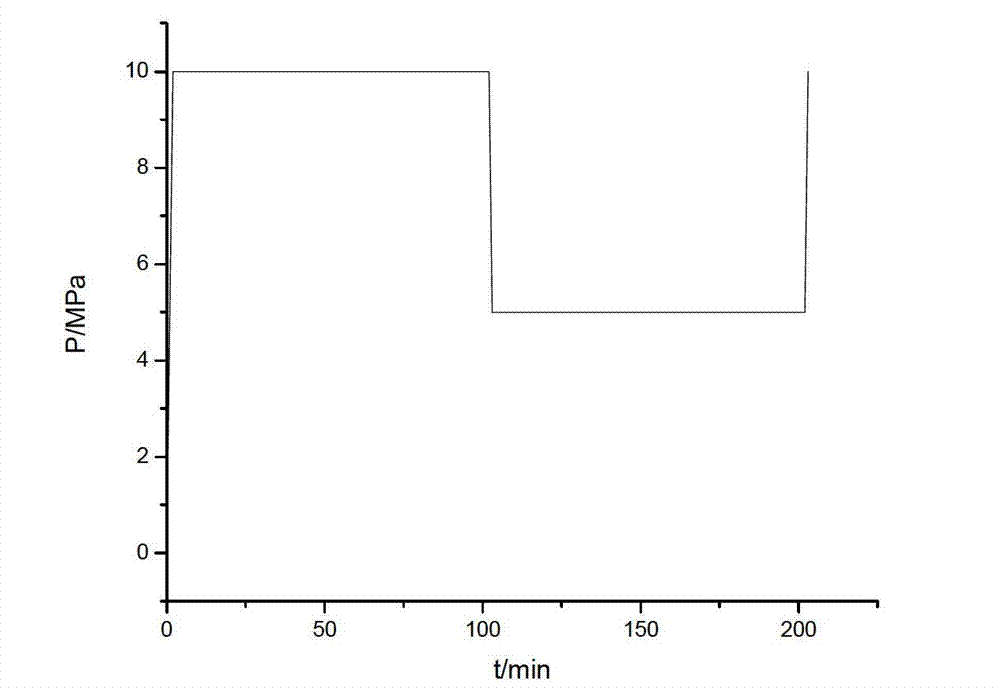

[0028] In this example, the electrochemical performance test of Al-Zn-In-Mg-Ti (1#) and Al-Zn-In-Mg-Ti-Ga-Mn (2#) was carried out according to the "Sacrificial Anode Electrochemical Performance Test" Method "GB / T 17848-1999, using the 4-day method test;

[0029] Test pressure: 4.5 and 6MPa alternately, the relationship between pressure change and time is as follows Figure 4 shown;

[0030] Temperature: changes with pressure (simulated deep sea depth);

[0031] Test time: 96 hours;

[0032] Dissolved oxygen: 0.6ppm;

[0033] Test results: as shown in Table 3 and Table 4;

[0034] Table 3 shows the open circuit potential and working potential:

[0035] Numbering

OCP / V

1d / V

2d / V

3d / V

4d / V

1#

-1.154

-1.094

-1.201

-1.026

-1.100

2#

-1.166

-1.116

-1.096

-1.036

-1.113

[0036] Table 4 shows the current efficiency:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com