Numerical control system-based tool radius compensation vector calculating method

A tool radius, numerical control system technology, applied in the numerical control field, can solve the problems of limited application scope and unfavorable promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

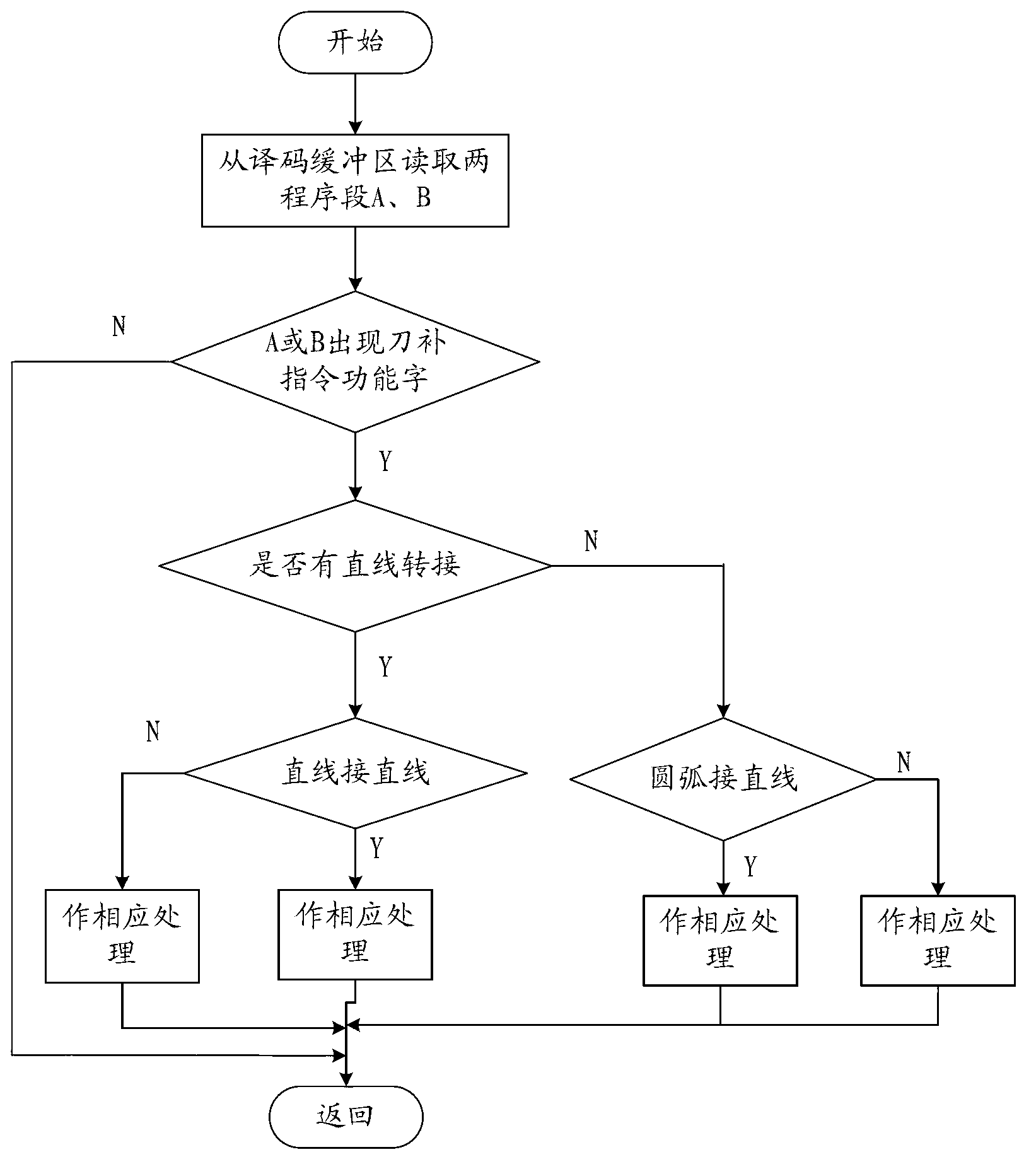

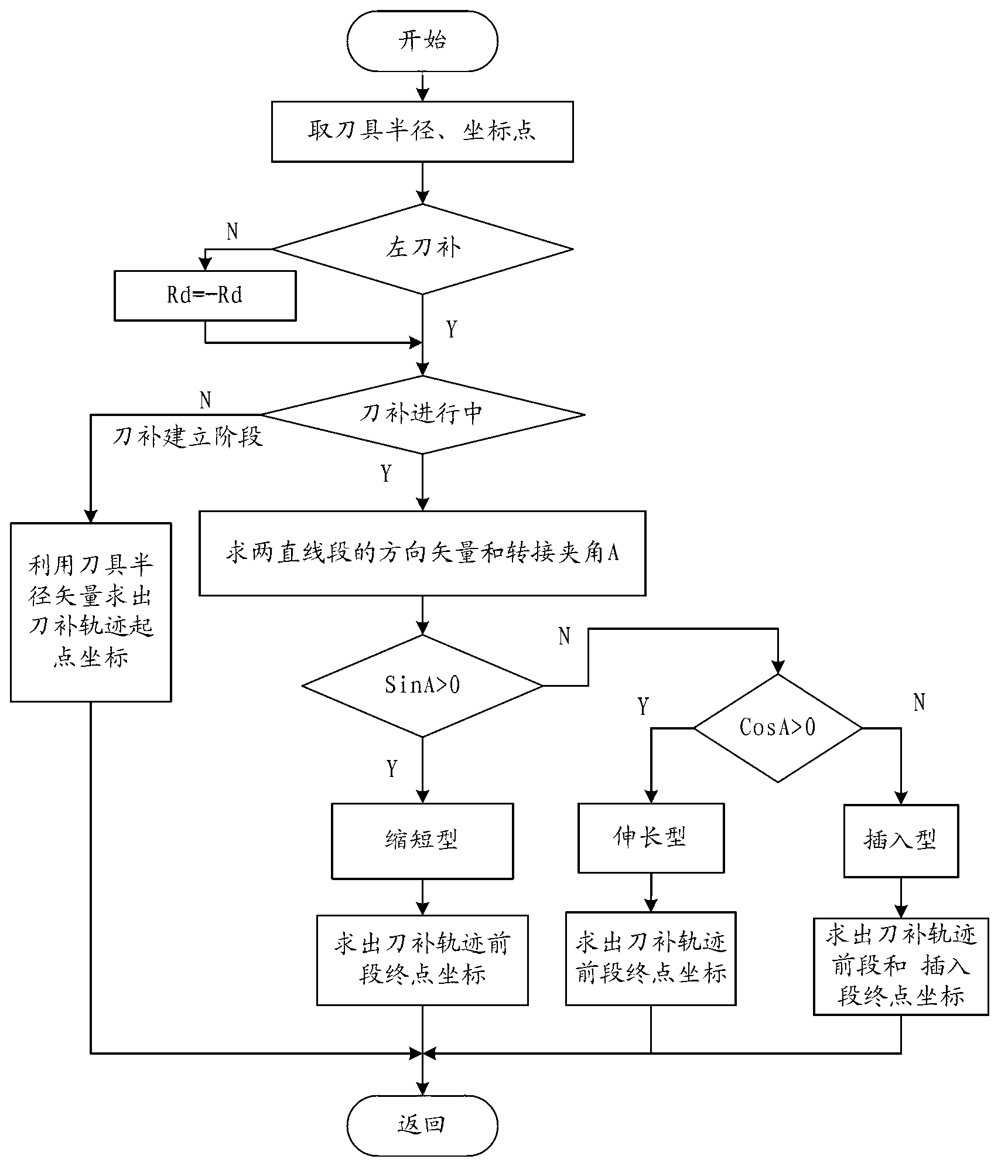

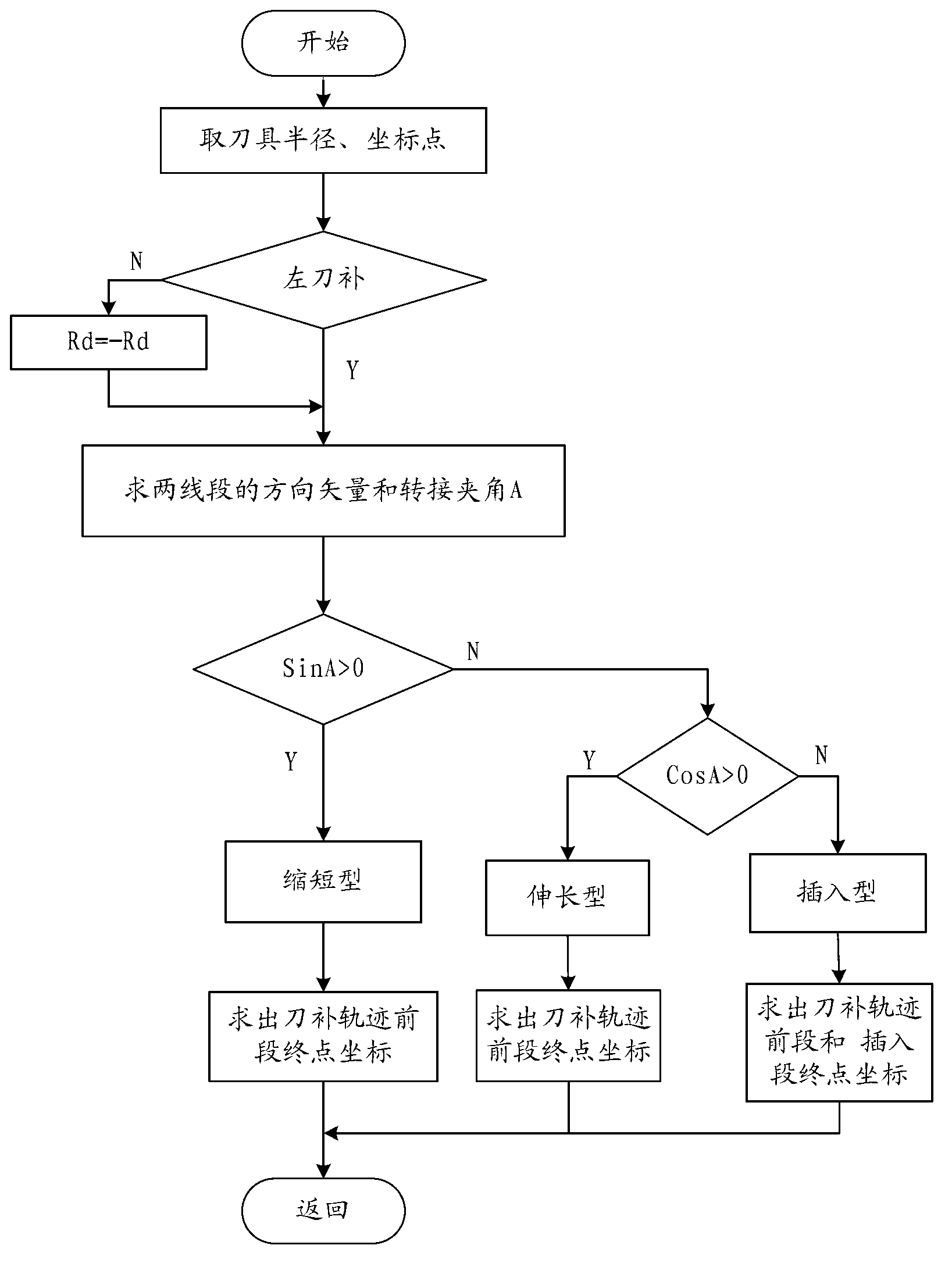

[0032] The invention proposes a vector calculation method for tool radius compensation in CNC system machining. In this method, in order to reduce the calculation amount of the tool center transition point and ensure the accuracy of interpolation processing, it is first necessary to extract the relevant data of tool compensation such as tool radius, tool compensation direction and coordinates from the interface file of the decoding module etc. After determining the line segment type, apply different calculation methods to obtain the corresponding direction vector. Secondly, use the direction vector of the straight line or arc to calculate the transition angle between the two line segments. After determining the transition angle, you can combine the previous tool compensation information to determine the transition type between the two programmed trajectories. Finally, use the tool radius vector and direction vector to obtain the straight line or arc equidistant line, and combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com