Fusion reactor liquid tritium breeder cladding module for realizing remote replacement by using single layer guide tube

A technology of tritium breeder and cladding module, which is applied in the field of liquid tritium breeder cladding modules of fusion reactors, can solve the problems of difficult processing, complex concentric hollow tube structure, poor reliability, etc., so as to reduce the difficulty of processing and manufacturing and improve the Safety and reliability, the effect of overcoming irregular shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

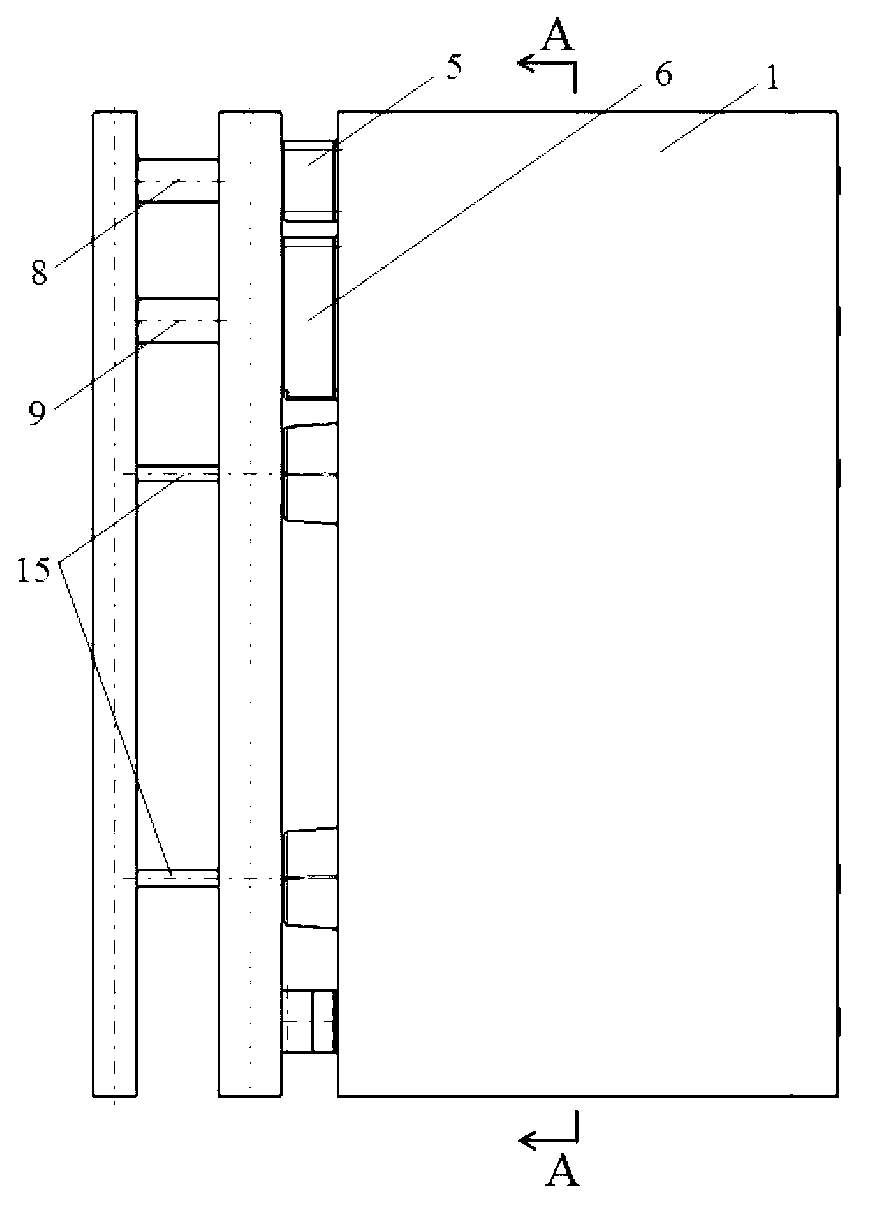

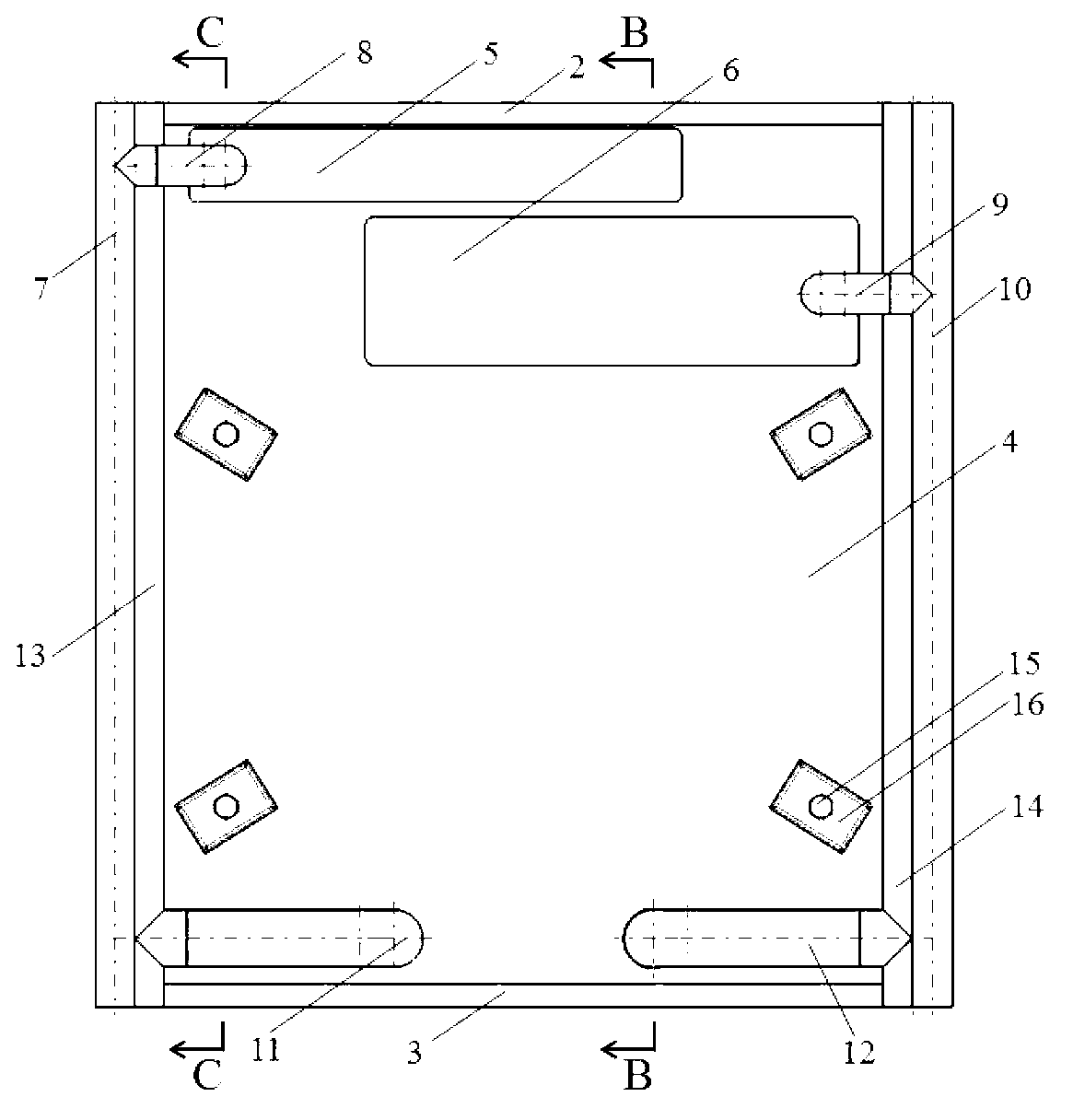

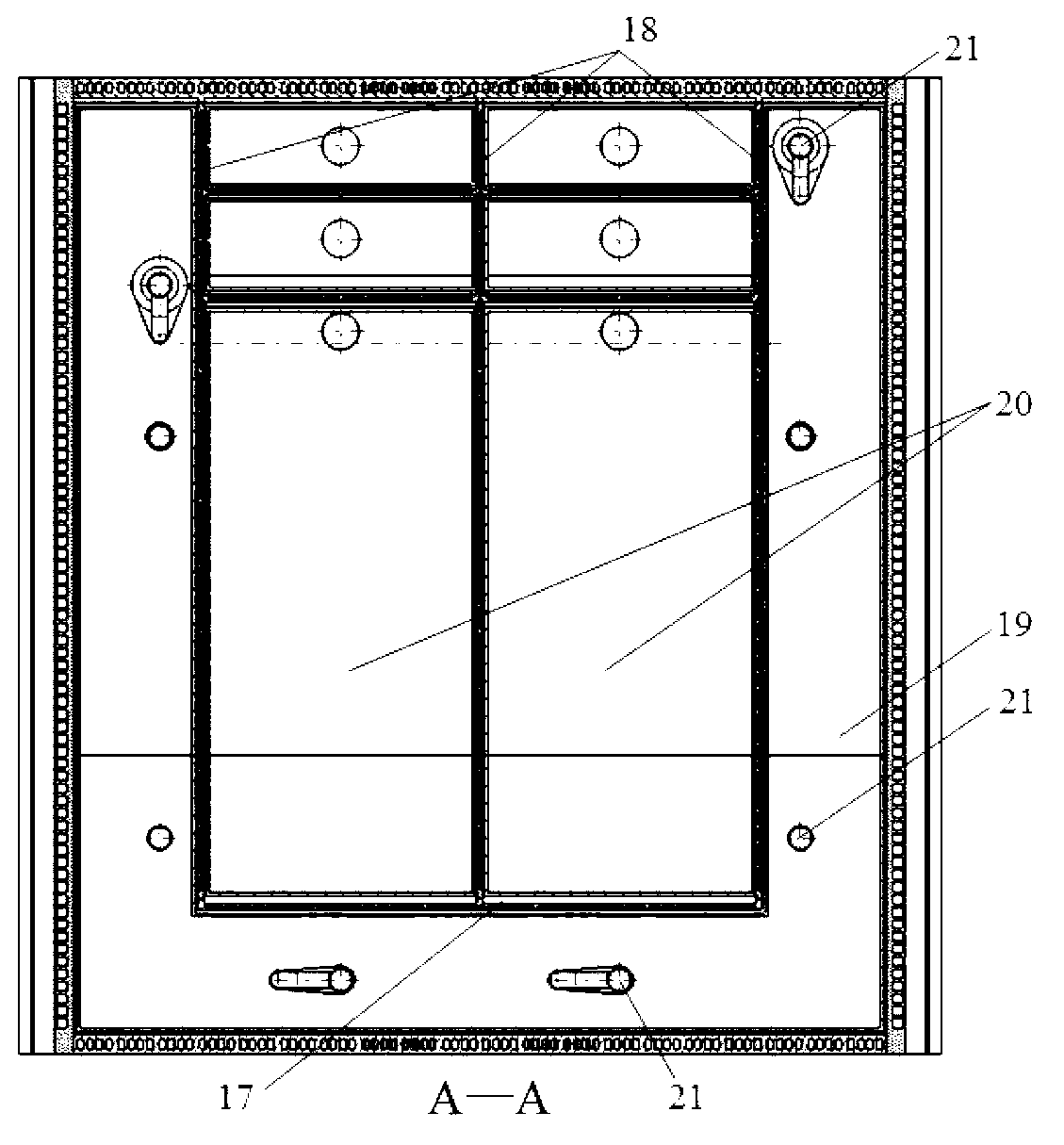

[0024] Such as figure 1 and figure 2 As shown, the first wall 1, the upper cover plate 2, the lower cover plate 3 and the back plate 4 form a box-like structure, and the upper part of the back plate 4 is provided with a liquid tritium breeding agent distribution box 5 and a liquid tritium breeding agent collection box 6. The tritium breeder flows from the liquid tritium breeder inlet main pipe 7 into the liquid tritium breeder inlet main pipeline 8, enters the liquid tritium breeder distribution box 5, divides into multiple branches and enters the tritium breeder area, and then gathers the liquid tritium breeder The converging box 6 flows into the outlet main pipe 10 of the liquid tritium breeder through the outlet main pipeline 9 of the liquid tritium breeder, wherein the shape of the tritium breeder area is as follows: image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com