Electric heating catalyst

An electric heating and catalyst technology, which is applied in the direction of electric heating devices, electrical components, chemical instruments and methods, etc., can solve the problems of short circuit between electrodes and shells, reduction of insulation resistance between electrodes and shells, etc., and achieve the effect of suppressing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] [Outline structure of EHC]

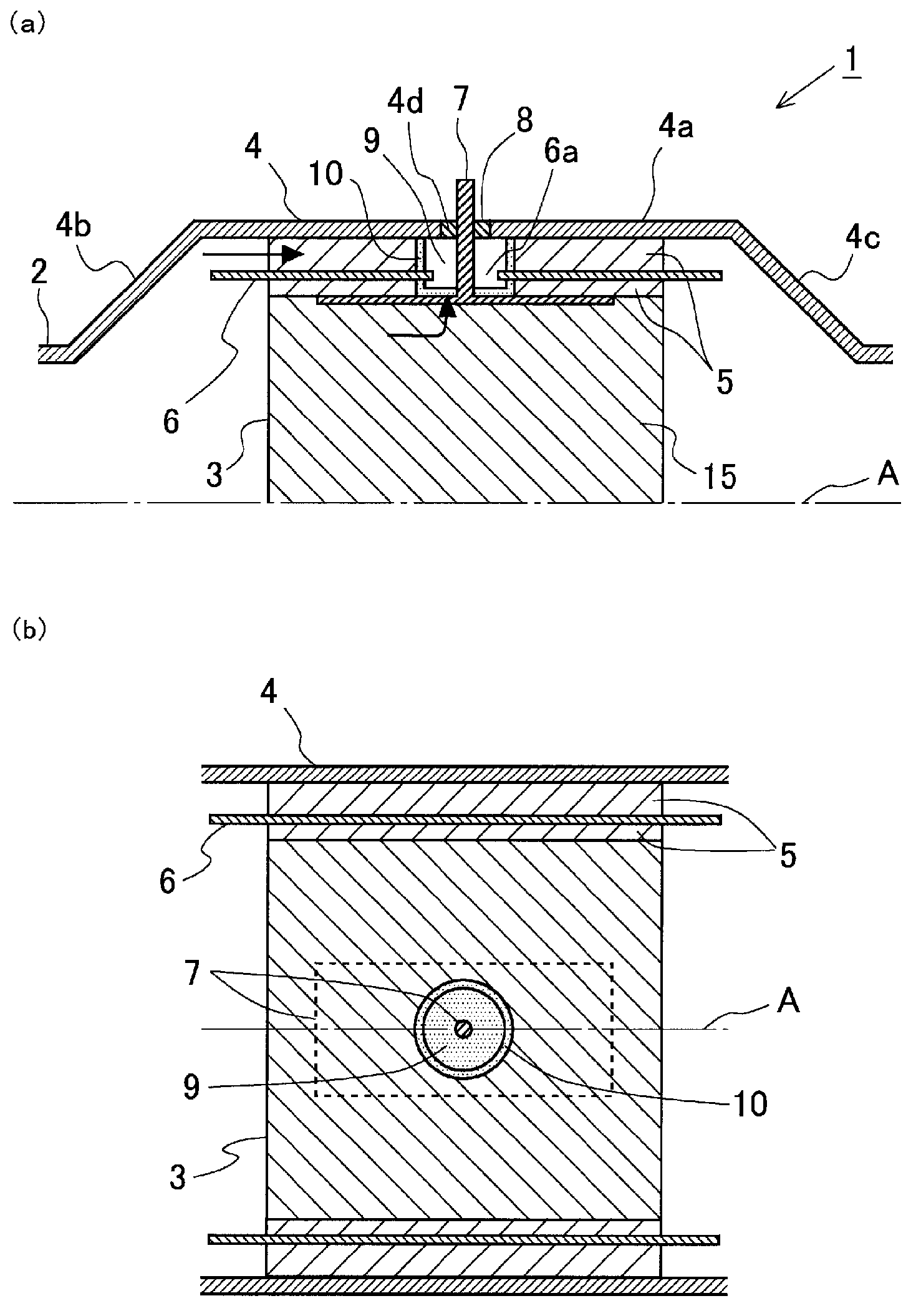

[0035] figure 1 It is a diagram showing a schematic configuration of an electrically heated catalyst (EHC) according to the present example. The EHC 1 according to the present embodiment is installed in an exhaust pipe of an internal combustion engine mounted on a vehicle. The internal combustion engine can be a diesel engine or a gasoline engine. Furthermore, the EHC 1 according to the present embodiment can also be used in a vehicle employing a hybrid system including an electric motor.

[0036] figure 1 (a) is a cross-sectional view of the EHC 1 longitudinally cut along the central axis A of the exhaust pipe 2 of the internal combustion engine. In addition, since the shape of EHC1 is line-symmetric with respect to the central axis A, therefore, in figure 1 In (a), for convenience of explanation, only the upper part of EHC1 is shown.

[0037]The EHC 1 according to this example includes a catalyst carrier 3 , a case 4 , a gasket 5 , a...

Embodiment 2

[0060] [Outline structure of EHC]

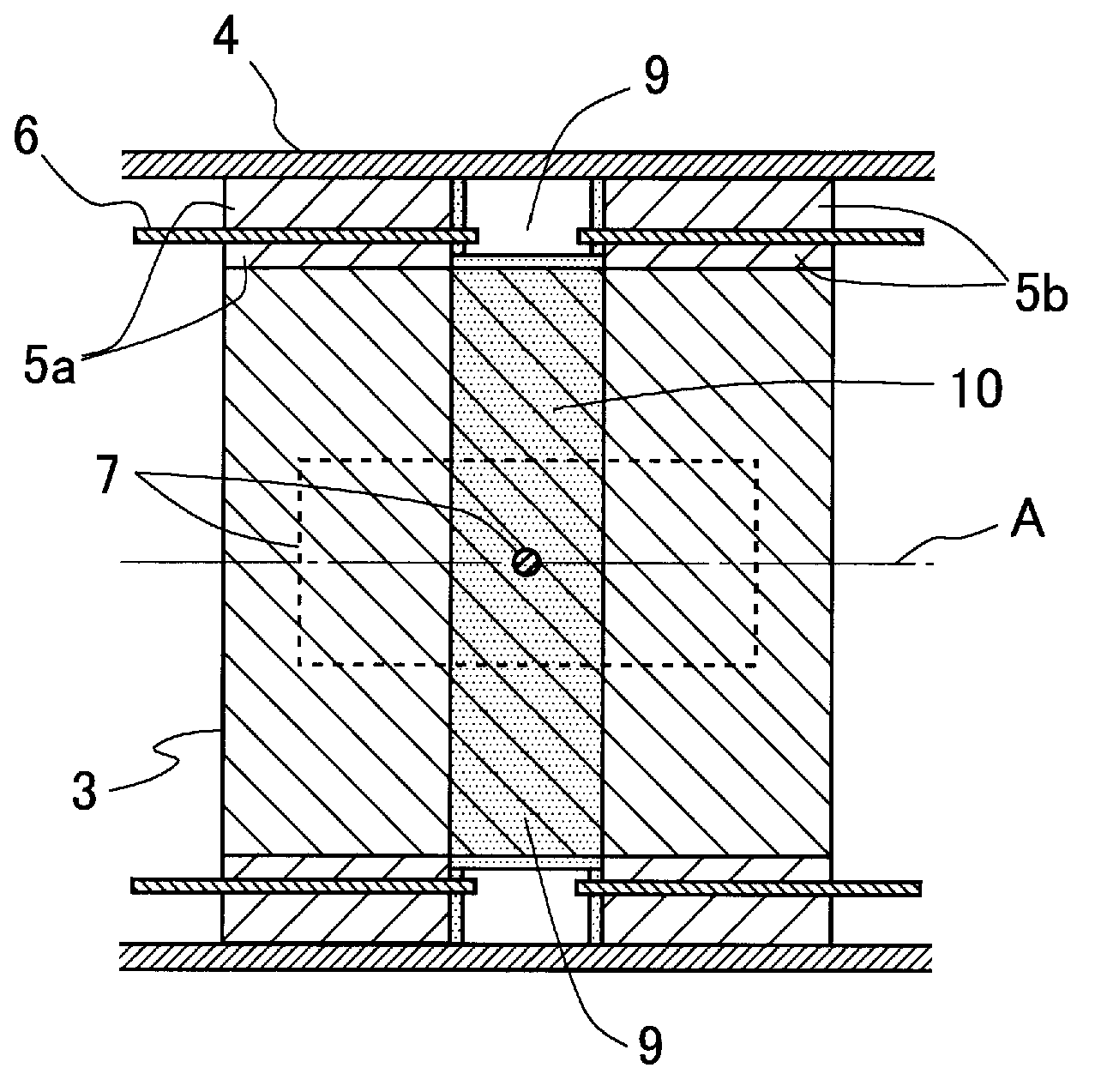

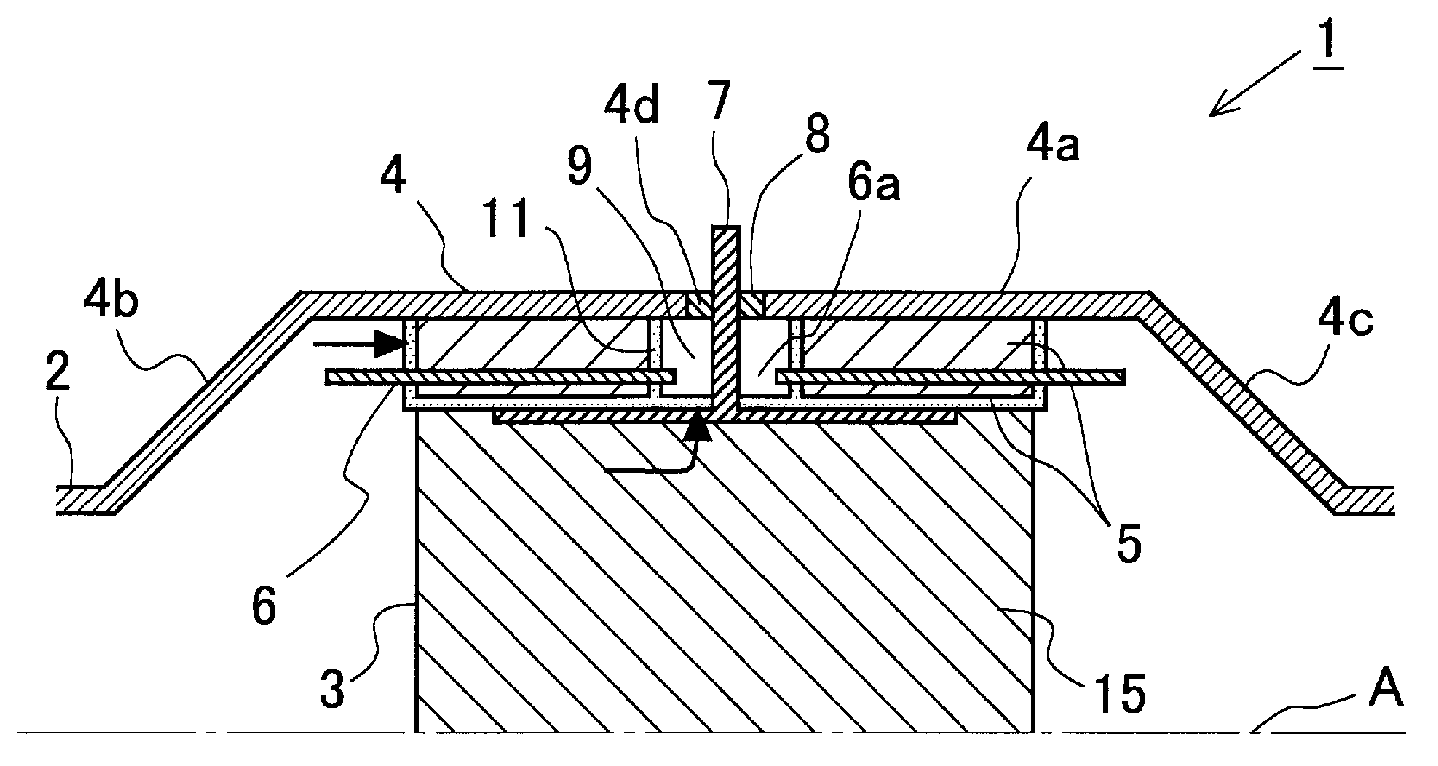

[0061] image 3 It is a diagram showing a schematic configuration of the EHC according to the present embodiment. Such as image 3 As shown, in this embodiment, in addition to the wall surface of the electrode chamber 9 , the entire outer peripheral surface of the catalyst carrier 3 and the upstream and downstream end surfaces of the mat 5 are also covered with the blocking member 11 . Like the closing member 10 according to Example 1, the closing member 11 is formed of a highly airtight insulating material that is higher in airtightness than the material forming the catalyst carrier 3 and the material forming the mat 5 and is electrically insulated. The structure other than that is the same as that of the EHC according to Example 1.

[0062] In addition, in this embodiment, the portion of the closing member 11 covering the wall surface of the electrode chamber 9 corresponds to the first closing member according to the present invention. ...

Embodiment 3

[0072] [Outline structure of EHC]

[0073] Figure 5 It is a diagram showing a schematic configuration of the EHC according to the present embodiment. Such as Figure 5 As shown, in this embodiment, the electrode chamber 9 is filled with the blocking member 12 . Like the closing member 10 according to Example 1, the closing member 11 is formed of a highly airtight insulating material that is higher in airtightness than the material forming the catalyst carrier 3 and the material forming the mat 5 and is electrically insulated. The structure other than that is the same as that of the EHC according to Example 1.

[0074] [Action and effect of the structure of the EHC related to the present embodiment]

[0075] exist Figure 5 In , arrows indicate the flow of exhaust gas and condensed water. In this embodiment, the electrode chamber 9 is closed by a highly airtight closing member 12 . Thereby, it is possible to suppress the exhaust gas and condensed water passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com