Apparatus for HCl synthesis with steam raising

A technology of steam bag and chlorine gas, which is applied in the direction of steam engine device, steam generation method using pressure combustion, steam superheating, etc., can solve complex and valuable heat not being used, problems and other problems, and achieve the goal of saving device cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

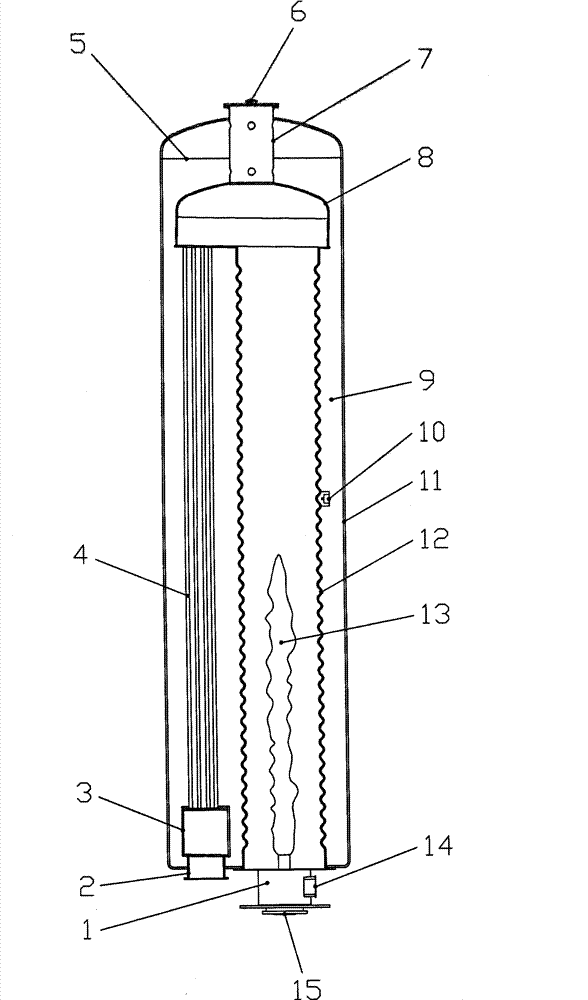

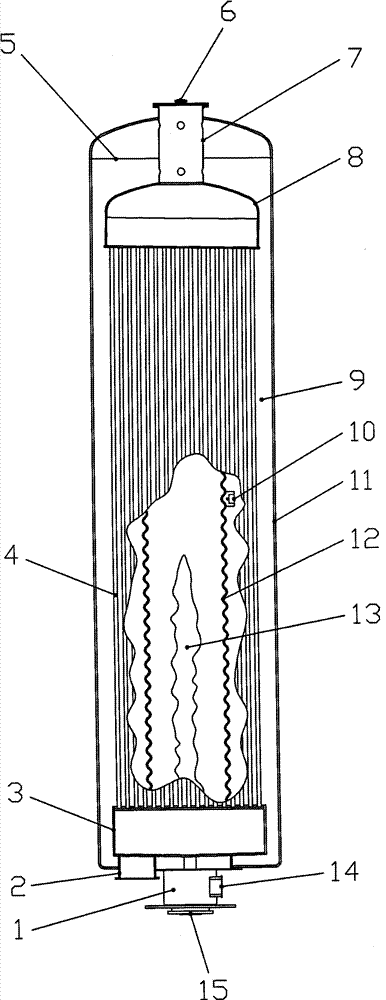

[0049] The device for carrying out the method is a drum boiler operating on the waste heat boiler principle. The waste heat boiler comprises a furnace body with an outer casing (11) and inner flame tubes which enclose a combustion chamber.

[0050] The HCl synthesis burner (1) is located at the opening of the flame tube (12), and the HCl synthesis burner (1) is provided with a hydrogen gas inlet (14) and a chlorine gas inlet (15). The combustion chamber is preferably delimited by a combustion chamber wall (12), for example made of steel and which may be formed with a corrosion-resistant cladding. The improved corrosion measurement probe (10) is installed within the confines of the boiler space (9), in the combustion space on the combustion chamber wall (12).

[0051] The flame direction of the flame (13) is shown from the bottom to the top. A tempering chamber (8) is located above the flame (13) with a steam collecting vessel (7) welded thereon, which is provided with a stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com