Vortex compressor type linear finish machining tool

A machine type and vortex technology, which is applied in the manufacture of tools, metal processing equipment, milling cutters, etc., can solve the problems of low production efficiency and high processing cost, and achieve the effects of improving production efficiency, reducing processing cost and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

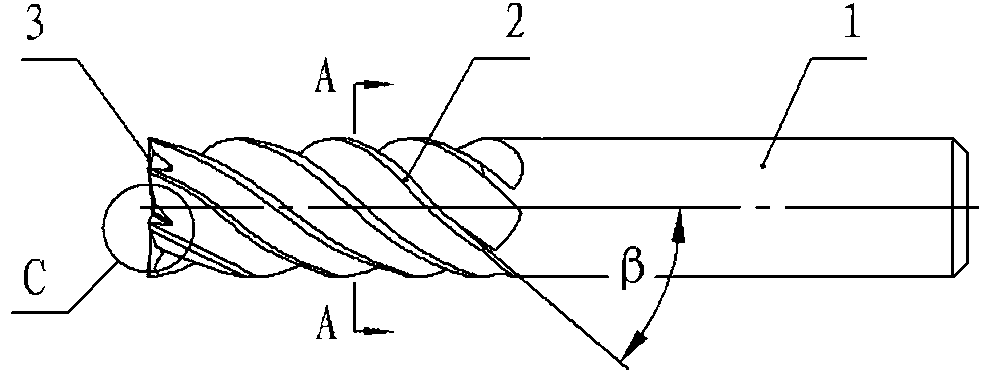

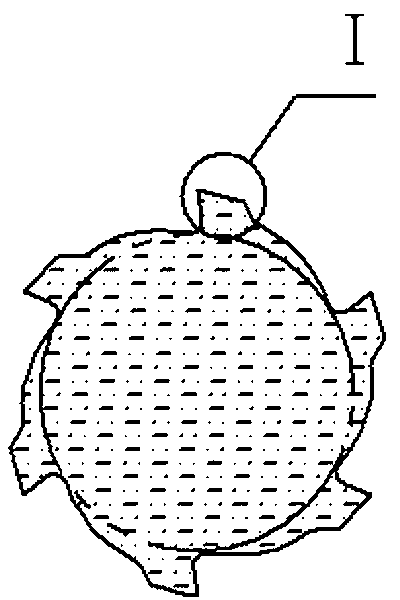

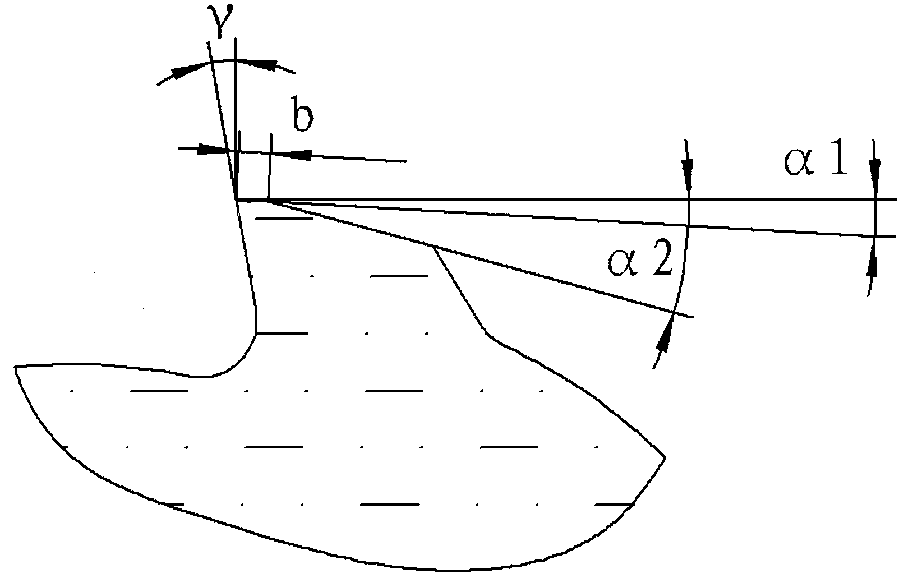

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 The scroll compressor profile finishing tool shown has a shank 1 and a cutting edge composed of a side edge 2, an end edge 3 and a chip flute. The side edge 2 has a rake angle γ and a relief angle, and the rake angle γ is 8 degrees to 10 degrees; there are six side edges 2, and the helix angle β of the side edges 2 is 45 degrees; the back of the side edge 2 has a first back and a second back, the width b of the first back is 0.4 mm, and the first back angle α1 is 0.5 degrees; the second relief angle α2 is 18 degrees; the groove bottom helix angle ε of the chip flute is 30 degrees, such as Figure 5 Shown; The axial cutting angle θ of the end edge 3 grooves is 18 degrees. Due to the addition of a transition edge bevel and transition relief angle at the rear of the side edge cutting edge, the combination of small transition relief angle and large relief angle, and the width of the transition edge bevel is controll...

Embodiment 2

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 The scroll compressor profile finishing cutter shown has a blade and a shank 1 composed of a side edge 2, an end edge 3 and a chip flute. The side edge 2 has a rake angle γ and a relief angle, and the rake angle γ is 8 degrees to 10 degrees; there are six side edges 2, and the helix angle β of the side edges 2 is 45 degrees; the back of the side edge 2 has a first back and a second back, the width b of the first back is 0.5 mm, and the first back angle α1 is 3.5 degrees; the second clearance angle α2 is 20 degrees; the groove bottom helix angle ε of the chip flute is 30 degrees, such as Figure 5 Shown; the axial cutting angle θ of the end edge 3 grooves is 20 degrees. Other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com