Method of assembling main pipe and branch pipe of welded pipeline and tooling used for assembling and welding

A welding method and technology in charge, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor correction effect, poor welding effect, uneven welding seam, etc., and achieve high support strength and convenient production. , Weld uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention adopts the pair welding method to weld the connecting parts of the main pipe and the branch pipe of the pipeline.

[0020] Before welding, spot welding is performed on the connection between the main pipe and the branch pipe, and the main pipe and the branch pipe are welded together. When spot welding is carried out, at least three sections of spot welding shall be carried out, and at least three spot welding sections shall be formed at the connection part, so that the relative position of the branch pipe and the main pipe is fixed. Preferably, the spot-fixed welding sections are evenly distributed at the connecting parts of the main pipe and the branch pipes of the pipeline, and the spot-fixed welding sections of the connecting parts are uniformly stressed, so as to prevent the branch pipes from tilting relative to the main pipe.

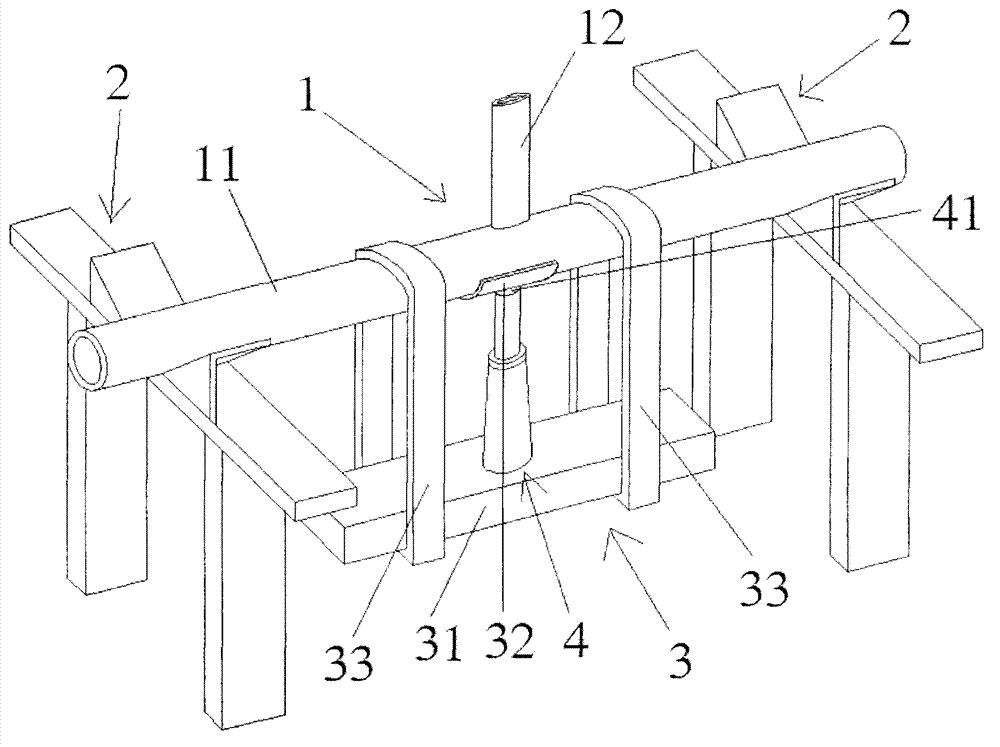

[0021] After the spot welding is completed, as shown in the figure, the main pipe 11 of the pipeline 1 formed by the spot wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com