Method for producing a motor vehicle component and motor vehicle component

A hybrid component and automobile technology, which is applied in the field of manufacturing automobile components, can solve the problems of high cost, high manufacturing and molding, and difficult positioning, and achieve the effects of improved energy absorption performance, improved collision energy absorption performance, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The same reference numerals are used in the figures for identical or similar components, even if repeated descriptions are omitted for reasons of simplification.

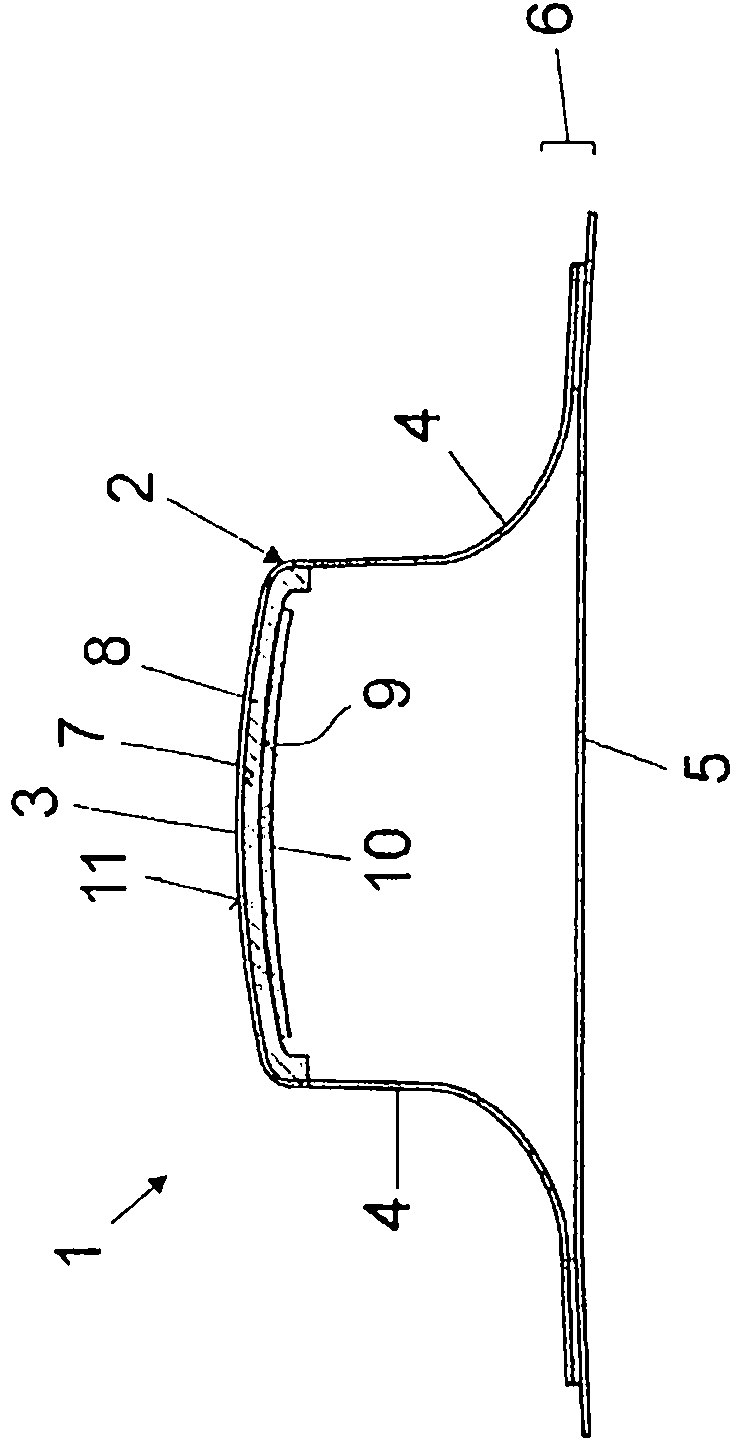

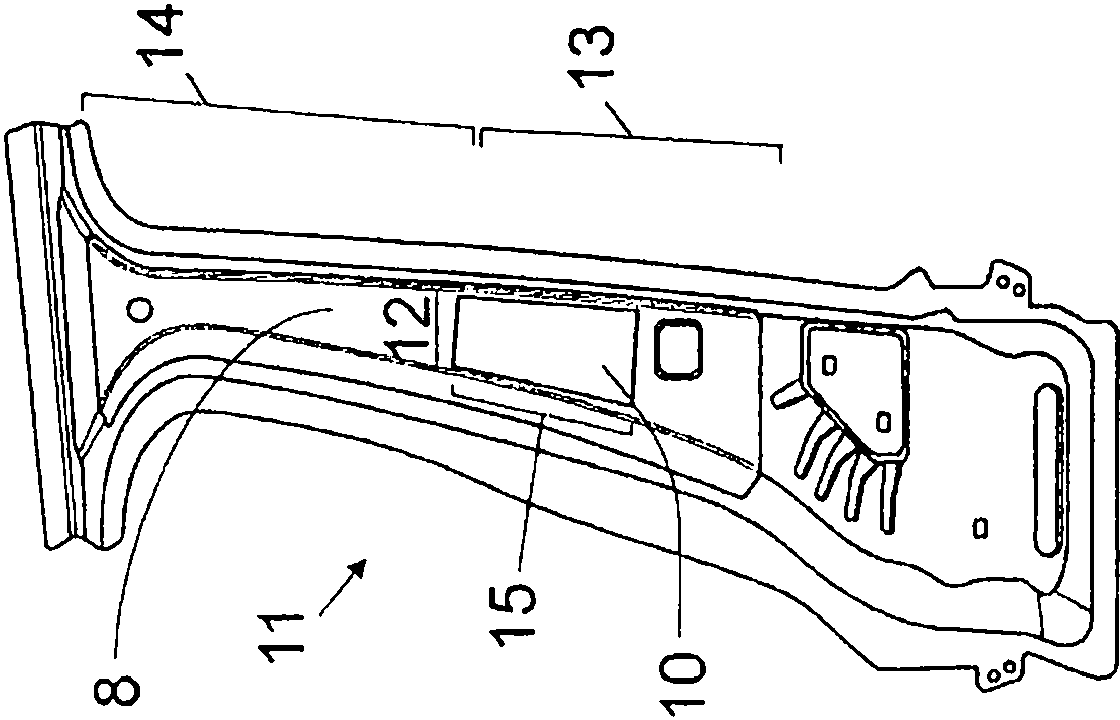

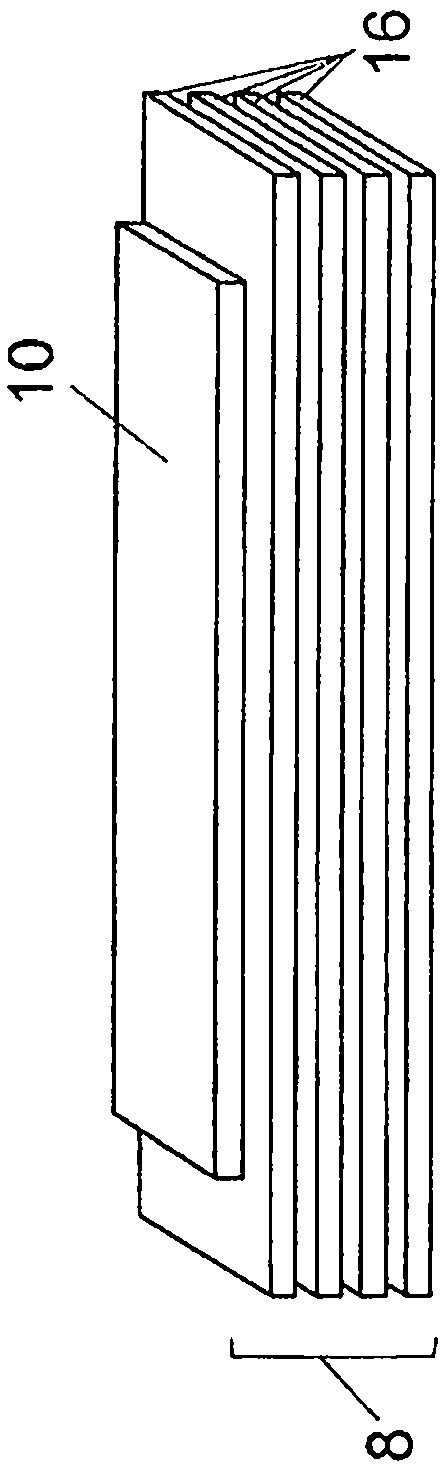

[0039] exist figure 1 A cross-sectional view of a vehicle mixing component 1 according to the invention is shown in . The vehicle mixing component 1 is designed in the form of a hat profile 2 . The hat profile 2 here comprises a bottom web 3 and a side 4 adjoining the bottom web 3 . The vehicle mixing component 1 is closed by a closing plate 5 at the end of the hat profile 2 . Arranged on the inner side 7 of the bottom web 3 is a reinforcing patch 8 which is formed from a plurality of fiber composite material layers, not shown in detail here. A metal layer 10 according to the invention is again arranged on the inner side 9 of the reinforcement patch 8 . The reinforcement patch 8 is thus terminated as a sandwich component on the outside by the bottom web 3 of the vehicle hybrid component 1 and covered on i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com