Induction quenching process for hardening alloy cast iron camshaft by using compressed air

An alloy cast iron, compressed air technology, applied in the field of heat treatment, can solve the problems of exceeding the ultimate strength, economic losses of enterprises, and failing to meet the hardness index requirements, and achieve the reduction of the possibility of cracking, uniform internal and external temperatures, and good performance indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

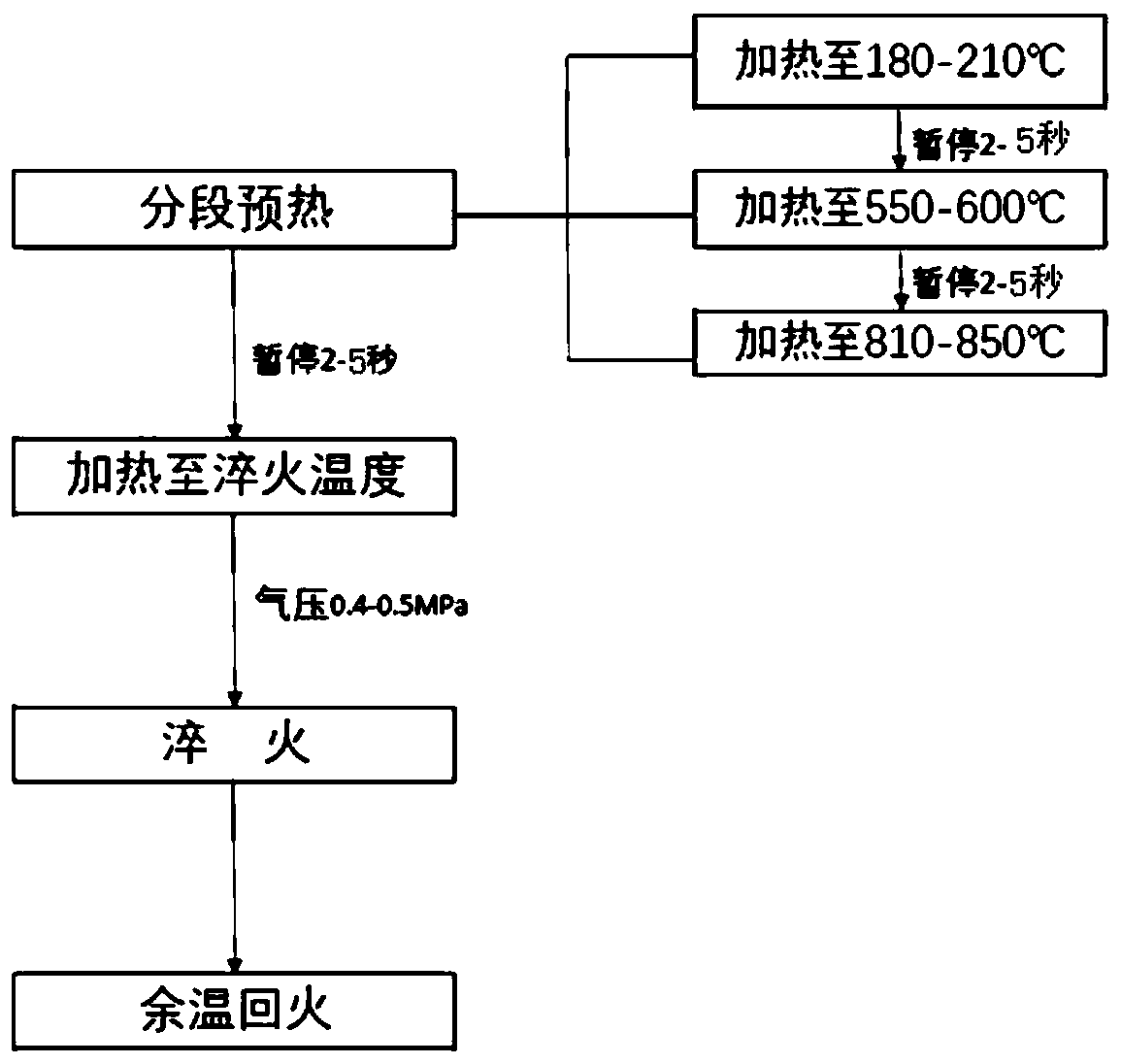

[0022] Embodiment 1, 30 camshaft workpieces, carry out induction hardening according to the following method:

[0023] S1. Preheating: first heat the camshaft to 190±10°C by induction, stop heating for 2 seconds to ensure that the heating part is evenly heated, then induction heat to 560±10°C, stop heating for 2 seconds; then induction heat the camshaft to 820±10°C, stop heating for 2 seconds; the heating rate of the three stages is 40-50°C / s;

[0024] S2. Heating to the quenching temperature: induction heating the camshaft preheated in step S1 to 900±10° C. at a heating rate of 40-50° C. / second;

[0025] S3. Quenching: using compressed air with a pressure of 0.4-0.5 MPa as the quenching medium, quenching the camshaft heated in step S2 for 50 seconds, and cooling the camshaft to 250-280° C.;

[0026] S4. Tempering at residual temperature: the camshaft quenched in step S3 is left at room temperature for 50 minutes, and the tempering process is completed by utilizing the residu...

Embodiment 2

[0027] Embodiment 2, 30 camshaft workpieces, carry out induction hardening according to the following method:

[0028] S1. Preheating: first heat the camshaft induction to 200±10°C, stop heating for 5 seconds to ensure that the heating part is evenly heated, then induction heat to 590±10°C, stop heating for 5 seconds; then induction heat the camshaft to 840±10°C, stop heating for 5 seconds; the heating rate of the three stages is 40-50°C / s;

[0029] S2. Heating to the quenching temperature: induction heating the camshaft preheated in step S1 to 930±10°C at a heating rate of 40-50°C / s;

[0030] S3. Quenching: using compressed air with a pressure of 0.4-0.5 MPa as the quenching medium, quenching the camshaft heated in step S2 for 40 seconds, and cooling the camshaft to 270-300° C.;

[0031] S4. Tempering at residual temperature: the camshaft quenched in step S3 is left at room temperature for 60 minutes, and the tempering process is completed by utilizing the residual temperatu...

Embodiment 3

[0032] Embodiment 3, 30 camshaft workpieces, carry out induction hardening according to the following method:

[0033] S1. Preheating: first heat the camshaft to 190±10°C by induction, stop heating for 3 seconds to ensure that the heating part is evenly heated, then induction heat to 570±10°C, stop heating for 3 seconds; then induction heat the camshaft to 830±10°C, stop heating for 3 seconds; the heating rate of the three stages is 40-50°C / s;

[0034] S2. Heating to the quenching temperature: induction heating the camshaft preheated in step S1 to 920±10°C at a heating rate of 40-50°C / s;

[0035] S3. Quenching: using compressed air with a pressure of 0.4-0.5 MPa as the quenching medium, quenching the camshaft heated in step S2 for 40 seconds, and cooling the camshaft to 260-290° C.;

[0036] S4. Tempering at residual temperature: the camshaft quenched in step S3 is left at room temperature for 50 minutes, and the tempering process is completed by utilizing the residual temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com