Docking round platform floating production storage system

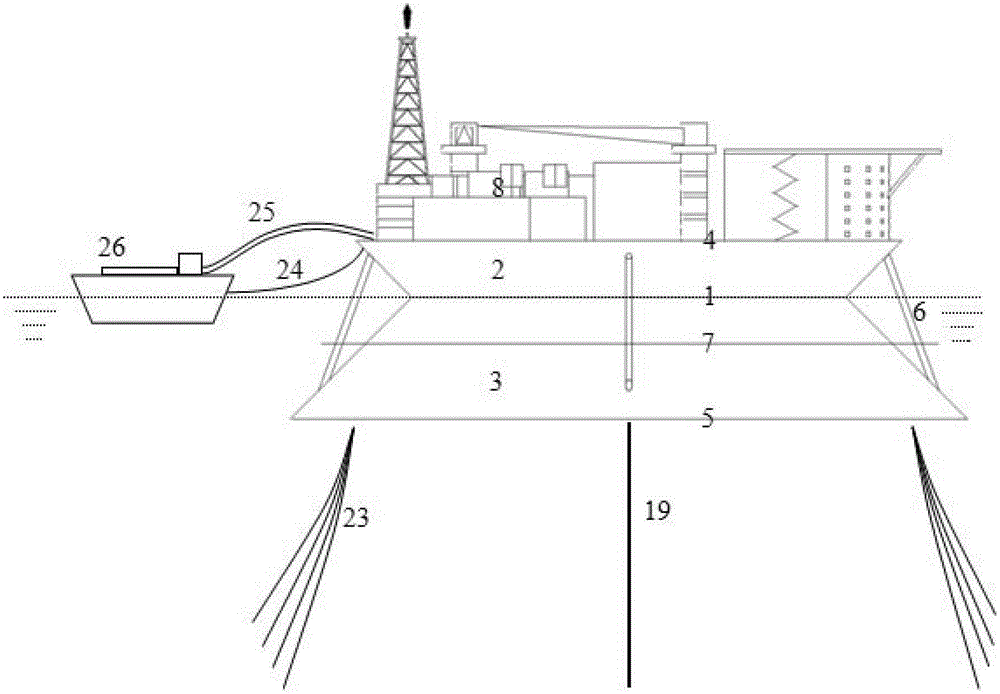

A floating production and storage, table top technology, applied in floating buildings and other directions, can solve the problems of large heave motion, poor roll motion performance, wear of inner turret and fluid joints, etc., to achieve large oil storage space, The effect of good sports performance and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

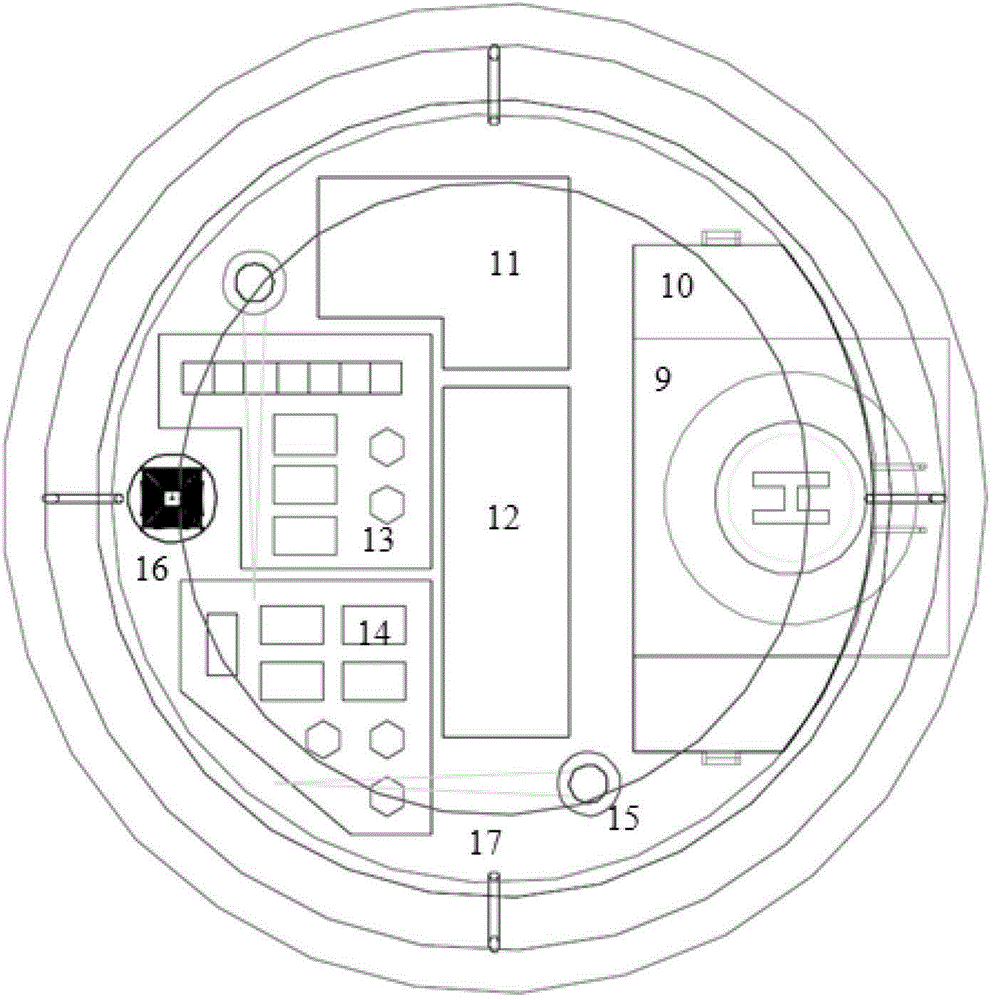

[0041] The deck is provided with a production module and a living module which are arranged independently of each other. The production module is located on one side of the deck, including a living office building and a helicopter deck located above the living office building. In the production module, the main generator module and the thermal station module with a higher safety factor are arranged near the living module, and the oil and gas treatment module and the flare tower with a lower safety factor are arranged behind the main generator and the thermal station module. To the side of the living area, and for the convenience of fire protection, a water treatment module is installed near the flare tower, which can provide a large amount of fire water.

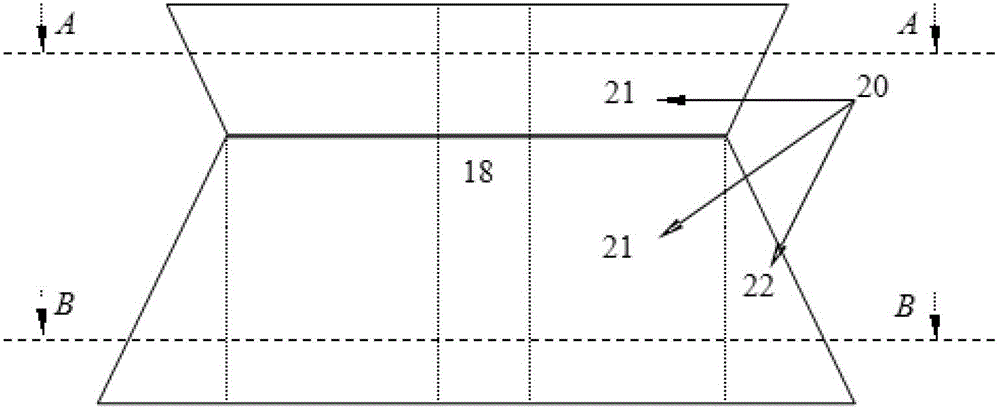

[0042] Similarly, the interior of the lower structure has a central cabin II at the same height as the central cabin II, and a plurality of watertight cabins surrounding the central cabin are arranged around the central cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com