Method for preparing N-sulfonyl substituted tetrahydro-beta-carboline derivative

A technology for sulfonyl and derivatives, which is applied in the field of N-sulfonyl-substituted tetrahydro-β-carboline derivatives and their preparation, and achieves the effects of high yield and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

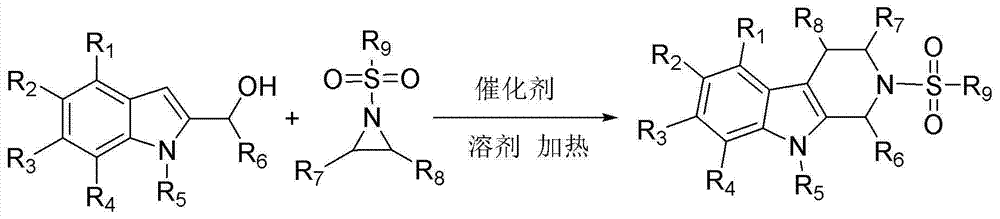

Method used

Image

Examples

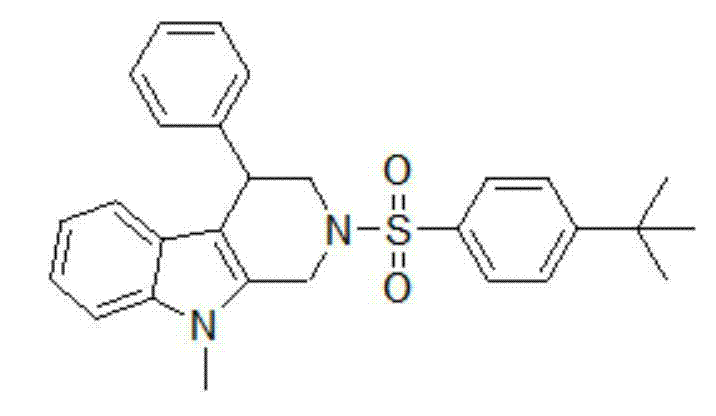

Embodiment 1

[0018] Add N-methylindole-2-methanol (0.6 mmol), 2-phenyl-1-p-toluenesulfonyl aziridine (0.5 mmol), scandium trifluorosulfonate (0.01 mmol) and ClCH2CH2Cl (3 mL), then heated to 83 °C and stirred for 2 hours (TLC monitoring). After the reaction, distilled water (10 mL) was added to terminate the reaction, extracted with ethyl acetate (30 mL × 3), dried over anhydrous magnesium sulfate, and the solvent was removed under reduced pressure to obtain a crude product, which was mixed with petroleum ether: ethyl acetate = 4:1 The solvent was the developing solvent, and the product (154 mg, yield: 74%) was isolated by column chromatography.

[0019] Its structural formula is:

[0020]

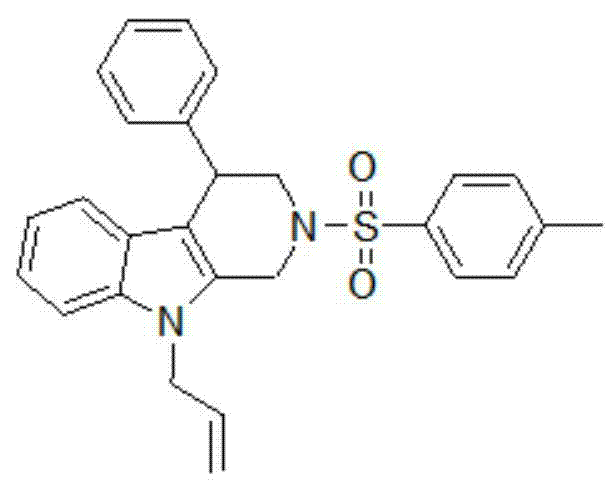

Embodiment 2

[0022] Add N-methylindole-2-methanol (0.6 mmol), 2-p-fluorophenyl-1-p-toluenesulfonyl aziridine (0.5 mmol), scandium trifluorosulfonate (0.01 mmol) to the reaction flask in sequence ), ClCH2CH2Cl (3 mL), then heated to 83 °C and stirred for 2 hours (monitored by TLC). After the reaction, distilled water (10 mL) was added to terminate the reaction, extracted with ethyl acetate (30 mL × 3), dried over anhydrous magnesium sulfate, and the solvent was removed under reduced pressure to obtain a crude product, which was mixed with petroleum ether: ethyl acetate = 4:1 The solvent was a developing solvent, and the product (167 mg, yield: 77%) was isolated by column chromatography.

[0023] Its structural formula is:

[0024]

Embodiment 3

[0026] Add N-methylindole-2-methanol (0.6 mmol), 2-p-chlorophenyl-1-p-toluenesulfonyl aziridine (0.5 mmol), scandium trifluorosulfonate (0.01 mmol) to the reaction flask in turn ), ClCH2CH2Cl (3 mL), then heated to 83 °C and stirred for 2 hours (monitored by TLC). After the reaction, distilled water (10 mL) was added to terminate the reaction, extracted with ethyl acetate (30 mL × 3), dried over anhydrous magnesium sulfate, and the solvent was removed under reduced pressure to obtain a crude product, which was mixed with petroleum ether: ethyl acetate = 4:1 The solvent was a developing solvent, and the product (169 mg, yield: 75%) was isolated by column chromatography.

[0027] Its structural formula is:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com