Technological process for brewing white spirit

A process and liquor technology, applied in the field of liquor brewing process, can solve problems such as climbing, and achieve the effect of improving labor efficiency, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

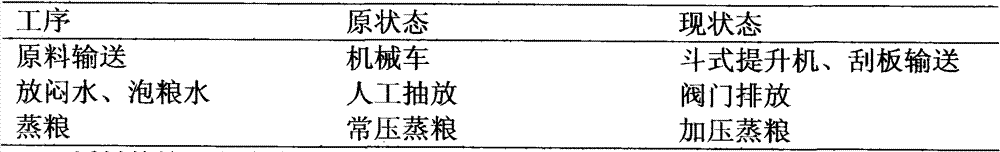

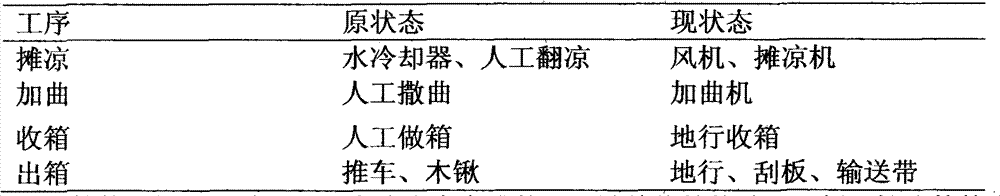

Method used

Image

Examples

Embodiment Construction

[0042] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

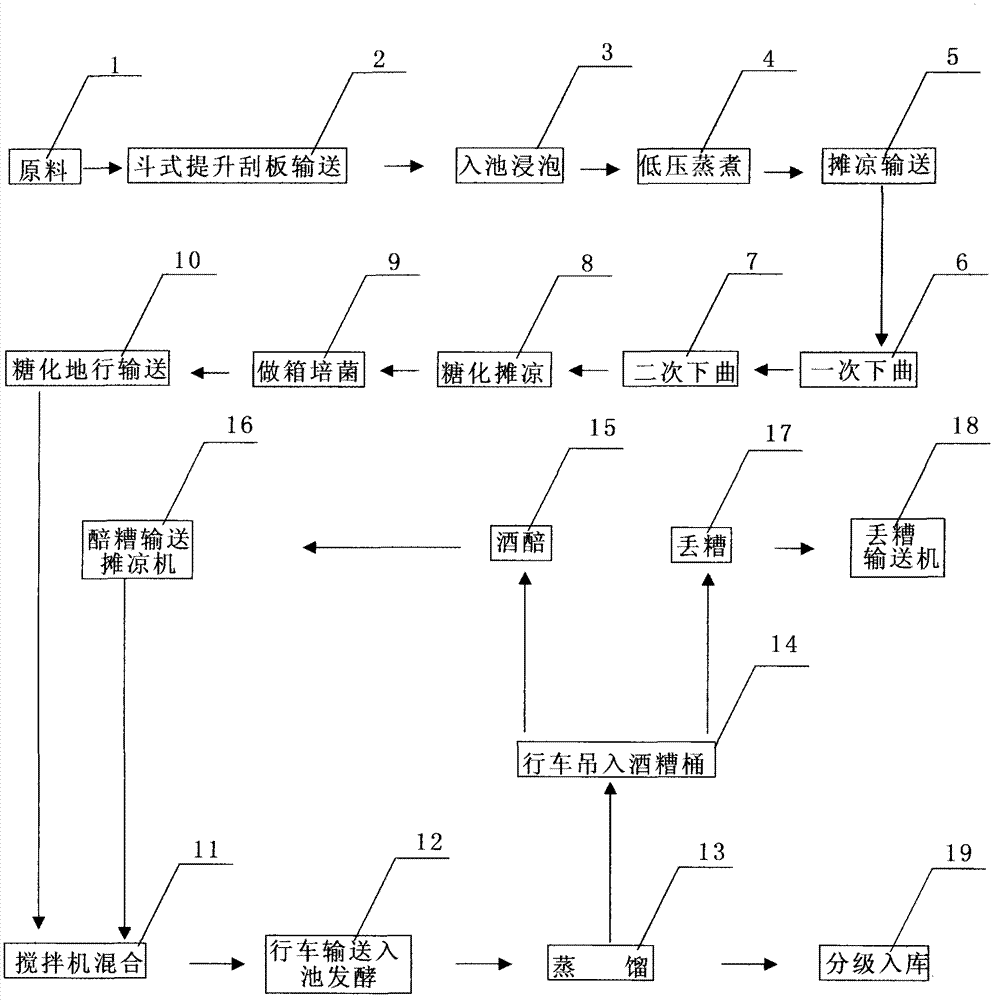

[0043] Such as figure 1 Shown, a kind of technological process of liquor brewing, is to use grain as raw material, carry out following process respectively:

[0044] 1. The raw material (1) is conveyed by a bucket-type lifting scraper (2) to the soaking pool for soaking (3), and the clinker is steamed under low pressure in a grain steamer (4), and the clinker is spread by the cooling conveyor During the process of transporting (5) to the saccharification booth (8) in the saccharification room, it is subjected to a lower koji (6) and a second koji (7), and then it is cultured in a box (9) in the saccharification room;

[0045] 2. The saccharification cultivation material is transported from the saccharification ground (10) to be mixed with the fermented grains (15) in the vertical mixer (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com