High-efficiency and energy-saving validamycin fermenting method

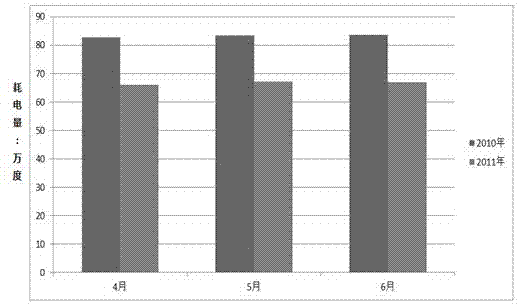

A technology of Jinggangmycin and fermentation method, which is applied in the field of microbial fermentation, can solve problems such as waste of dissolved oxygen, premature aging of hyphae, and destruction of cell components, and achieve the effects of reducing energy consumption and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Inoculate the strain of Streptomyces hygroscopicus Jinggang into the liquid fermentation medium, control the inoculum amount to 12%, and the fermentation temperature is 40°C; the liquid fermentation medium contains 120g of rice flour, 20g of peanut cake powder, NaCl2g, CaCO 3 1g . ,KH 2 PO 4 1g, the pH value is 7;

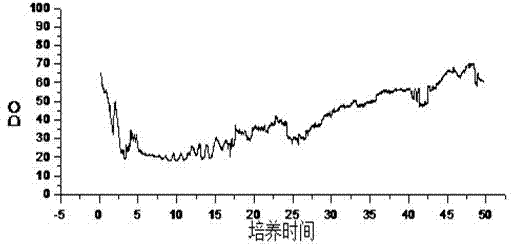

[0022] 2) At the initial stage of fermentation, the ventilation volume should be controlled at 3000m 3 / h, ferment from 30h to the end of fermentation, control the dissolved oxygen to 30%, and control the stirring speed to 120r / min during the fermentation process.

Embodiment 2

[0024] 1) Inoculate Streptomyces hygroscopicus var. Jinggang into the liquid fermentation medium, control the inoculation amount to 8%, and the fermentation temperature is 35°C; the liquid fermentation medium contains 70g of rice flour, 10g of peanut cake powder, 1g of NaCl, and CaCO 3 1g . ,KH 2 PO 4 1g, pH 6;

[0025] 2) At the initial stage of fermentation, the ventilation volume should be controlled at 2500m 3 / h, ferment 25h to the end of fermentation, control the dissolved oxygen to 20%, and control the stirring speed to 50r / min during the fermentation process.

Embodiment 3

[0027] 1) Inoculate Streptomyces hygroscopicus varietal Jinggang into the liquid fermentation medium, control the inoculation amount to 15%, and the fermentation temperature is 45°C; the liquid fermentation medium contains 150g of rice flour, 30g of peanut cake powder, NaCl2g, CaCO 3 2g . ,KH 2 PO 4 3g, the pH value is 8;

[0028] 2) At the initial stage of fermentation, the ventilation volume should be controlled at 3500m 3 / h, ferment for 35h to the end of fermentation, control the dissolved oxygen amount to 50%, and control the stirring speed to 150r / min during the fermentation process.

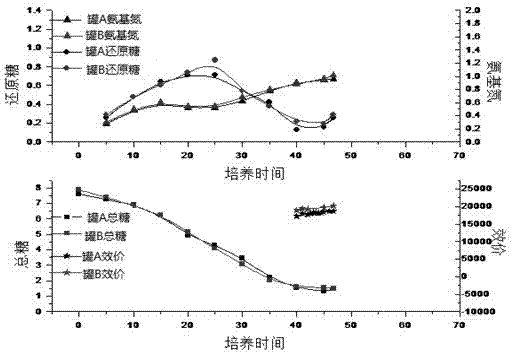

[0029] According to embodiment 1, get fermentor A, fermenter B to carry out following test according to the step described in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com