One-step preparation method and device of fully drawn yarn (FDY) or FDY differential shrinkage combined filament yarn

A technology of different shrinkage mixed fiber yarn and preparation device, which is applied in the field of synthetic fiber manufacturing, can solve the problems of increasing the different shrinkage mixed fiber yarn, POY/FDY different shrinkage mixed fiber yarn with low strength, single variety, etc., and achieves flexible spinning. , Good stability of product quality, various effects of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

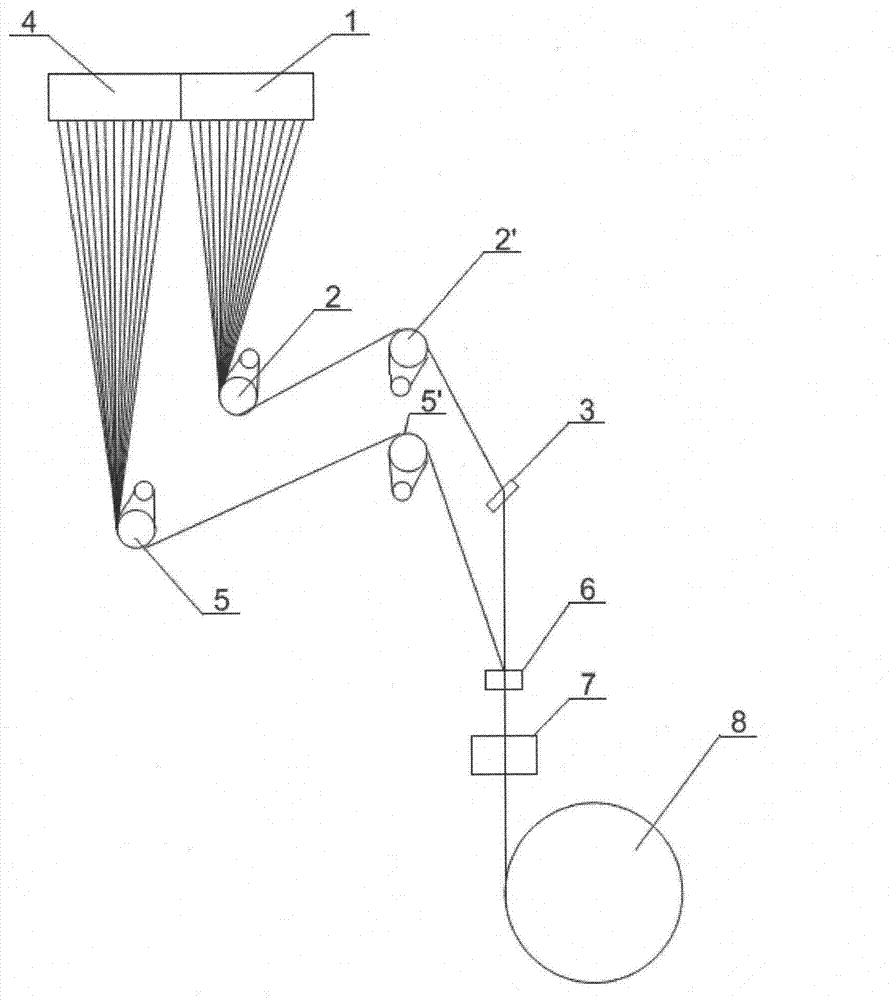

[0033] Such as figure 1 As shown, it is a schematic structural diagram of a preparation device for compounding FDY / FDY different shrinkage mixed filaments after setting, including a first spinning unit 1 and a second spinning unit 4 . The yarn output from the first spinning assembly 1 is drawn by the first hot roller 2, shaped by the second hot roller 2' and diverted by the diverter 3 in sequence to form the first fully drawn yarn, and the first fully drawn yarn FDY is input into the parallel yarn 6, the filaments output by the second spinning assembly 4 are sequentially drawn by the third hot roller 5 and shaped by the fourth thermal roller 5' to form the second fully drawn filament, and the second fully drawn filament is input into the doubling device 6 , after the parallel device 6 combines all the input yarns, they pass through the network device 7 and the winding roller 8 in turn to obtain FDY / FDY different shrinkage mixed fiber yarns.

Embodiment 2

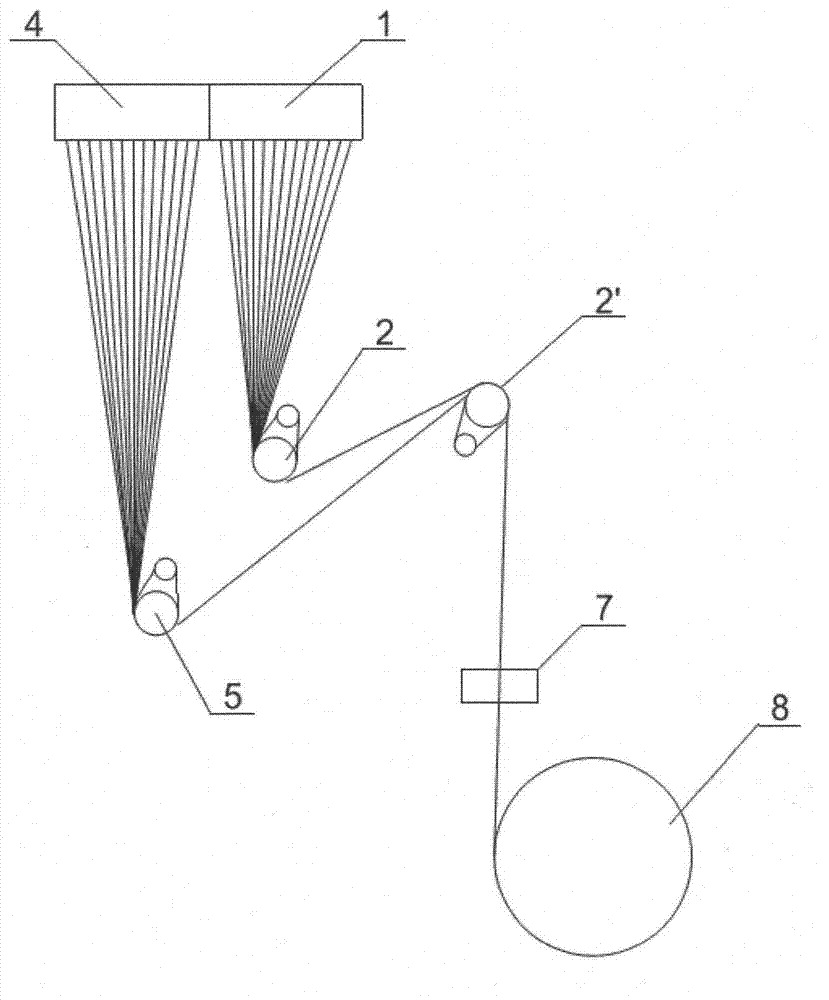

[0035] Such as figure 2 As shown, it is a schematic structural diagram of a preparation device for compounding FDY / FDY different shrinkage mixed filaments before setting, including a first spinning unit 1 and a second spinning unit 4 . The first spinning output from the first spinning assembly 1 is drawn by the first hot roller 2 in turn, and then input to the second heating roller 2' for shaping to form the first fully drawn yarn, and the second spinning output from the second spinning assembly 4 After being drafted by the third hot roller 5, it is input into the second hot roller 2' for shaping to form the second fully-drawn yarn. After the second hot roller 2' combines the first fully-drawn yarn and the second fully-drawn yarn, Through the network device 7 and the winding roller 8, the FDY / FDY different shrinkage mixed fiber yarn is obtained.

Embodiment 3

[0037] Raw materials: polyethylene terephthalate chips (intrinsic viscosity 0.72dL / g, melting point 260-268°C), purchased from Shanghai Petrochemical Co., Ltd.;

[0038] Equipment: adopt the preparation device provided in Example 1;

[0039] Preparation method: After the polyethylene terephthalate spinning solution is sprayed out from the first spinning assembly 1, it passes through the first hot roller 2 with a temperature of 70°C and a speed of 1000m / min, and a temperature of 90°C and a speed of 1000m / min. A second hot roll 2' at 2800 m / min and a diverter 3 to form a first fully drawn yarn (FDY). After the polyethylene terephthalate spinning solution is sprayed out by the second spinning assembly 4, it passes through the third hot roller 5 with a temperature of 90°C and a speed of 1000m / min, and a temperature of 130°C and a speed of 4500m / min. The fourth hot roller 5' of min forms the second fully drawn yarn (FDY). The first fully drawn yarn and the second fully drawn yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com