Measurement method of liquid level and position of tank body

A measurement method and technology for body fluids, which are applied to the liquid level indicator for physical variable measurement, etc., can solve the problems of difficulty in measuring oil-water interface and high price, and achieve the effects of improving system measurement accuracy, reducing influence and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The measuring device, measuring principle and specific operation mode used in the method for measuring the liquid level and interface of the tank body of the present invention will be further described below.

[0041] Firstly, the measuring device for tank liquid level and boundary level used in the present invention will be illustrated with reference to the accompanying drawings.

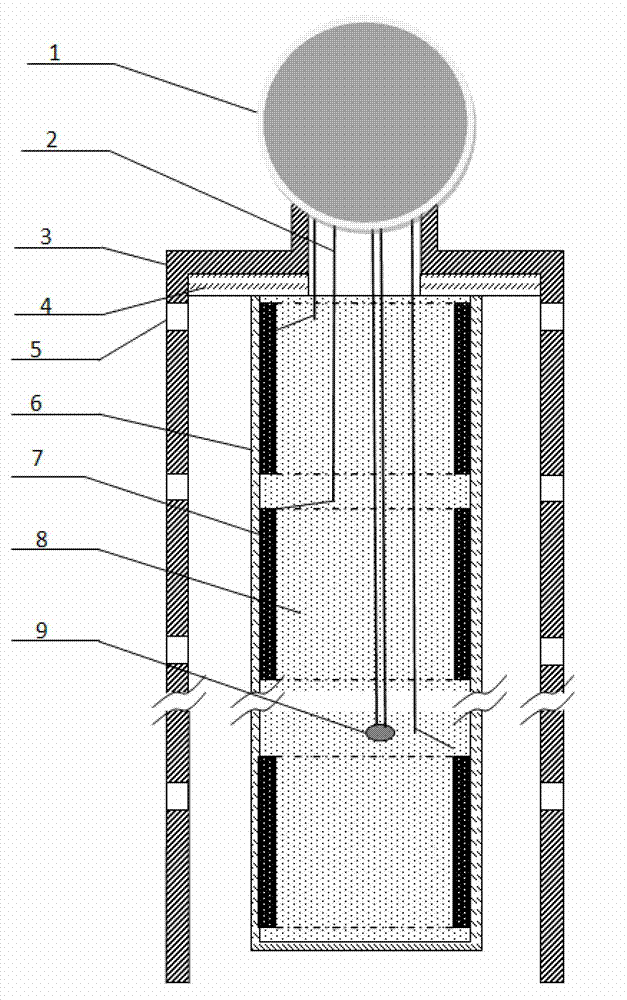

[0042] Such as figure 1 As shown, the measurement device of this embodiment includes: instrument circuit processing part 1, instrument lead wire 2, instrument metal stainless steel outer wall 3, sealing part 4, liquid level through hole 5, high temperature resistant plastic insulating layer 6, internal metal electrode 7, potting Sealing material 8, temperature sensor 9.

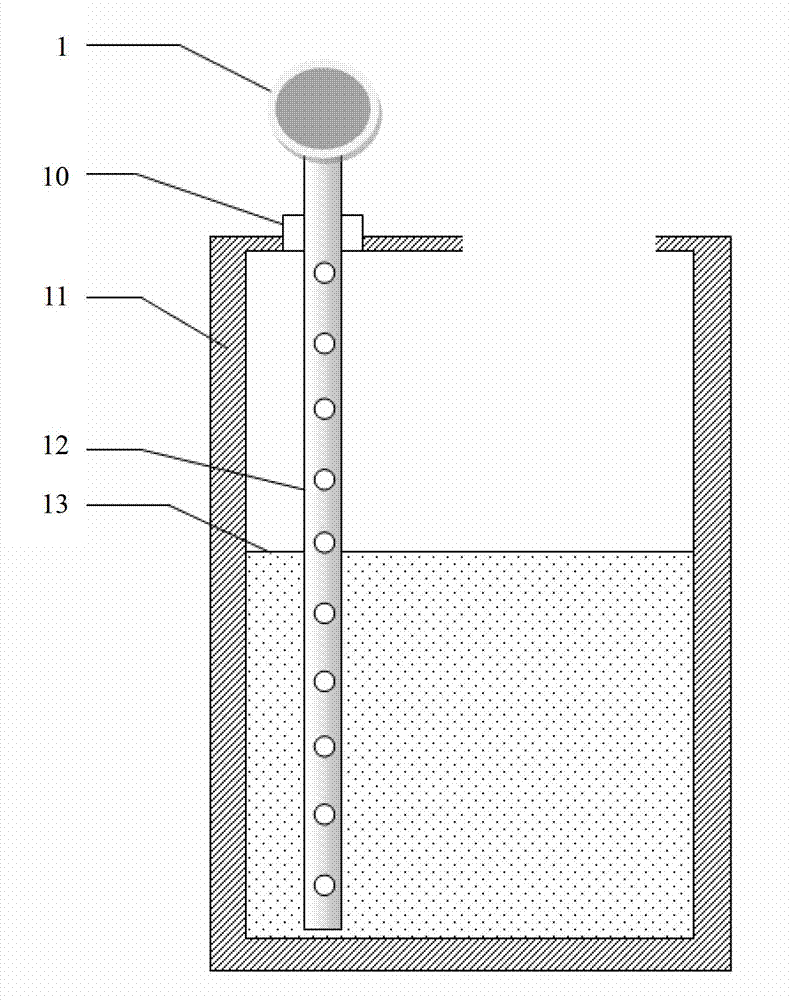

[0043] During installation and use, the relative positions of the installation flange 10, the tank body 11, the measuring instrument 12 and the liquid level 13 are as follows: figure 2 shown.

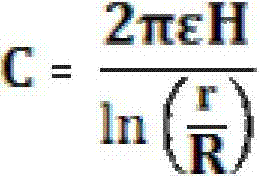

[0044] The measurement pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com