Integrated method of carbon nano tube heat dissipation structure and electronic device

A heat dissipation structure and technology of electronic devices, applied in the field of microelectronics technology, can solve problems such as reducing production efficiency and increasing process complexity, and achieve the effects of improving production efficiency, avoiding process complexity, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

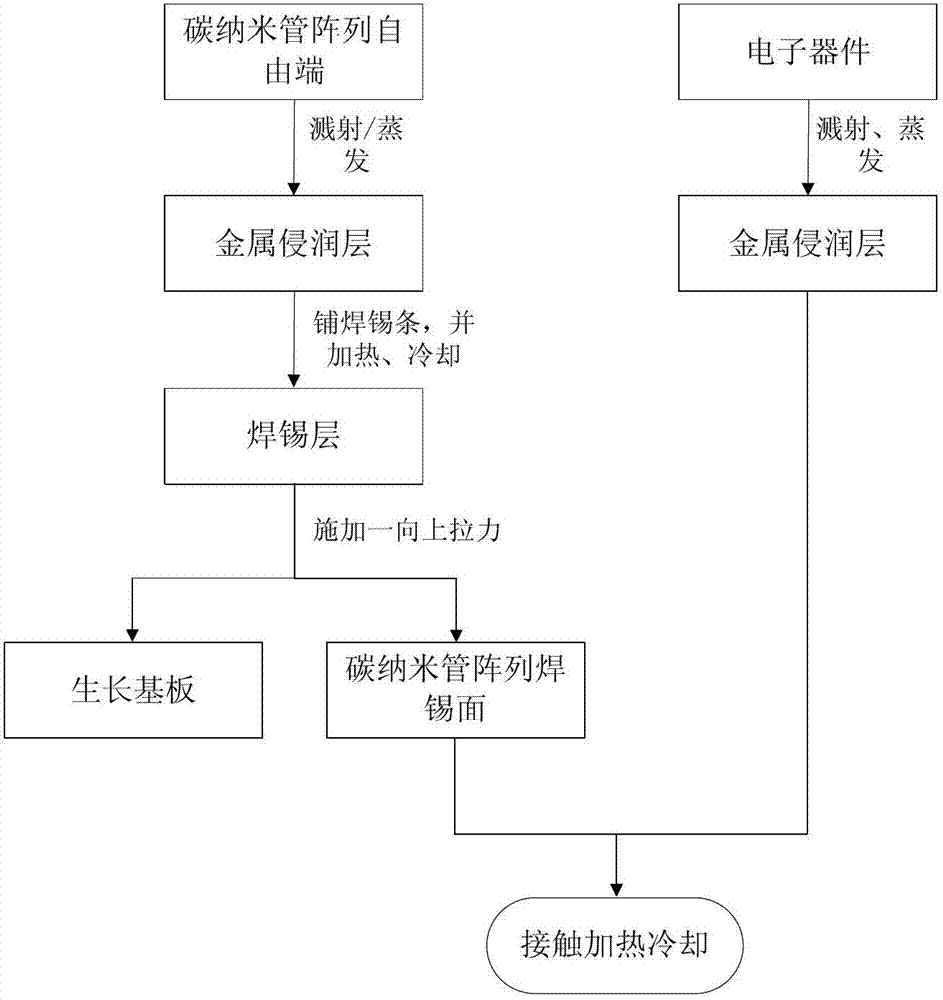

[0021] A method for integrating a carbon nanotube heat dissipation structure and an electronic device, comprising the following steps:

[0022] 1. Put the 8mm×8mm silicon dioxide chip with aligned carbon nanotube array and the silicon chip with Au thin film heating wire to be integrated into the radio frequency magnetron sputtering equipment, under Ar gas pressure 0.5Pa, power 100W Under the process conditions, a Ni metal target was used to sputter for 60 minutes, so as to deposit a Ni metal wetting layer with a thickness of about 5 microns on the top of the free end of the carbon nanotube and the back of the silicon wafer with the Au film heating wire.

[0023] 2. Place the silicon dioxide wafer with the aligned carbon nanotube array on the hot stage, take three 8mm long Sb60 / Pb40 solder strips, and spread th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com