Composite battery membrane and preparation method thereof

A composite battery and diaphragm technology, which is applied to battery pack parts, chemical instruments and methods, circuits, etc., can solve the problems of large thickness of safety diaphragm, affecting the quality of safety diaphragm, affecting the performance of diaphragm, etc., and achieves good processing performance and thickness The effect of convenient and flexible control and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

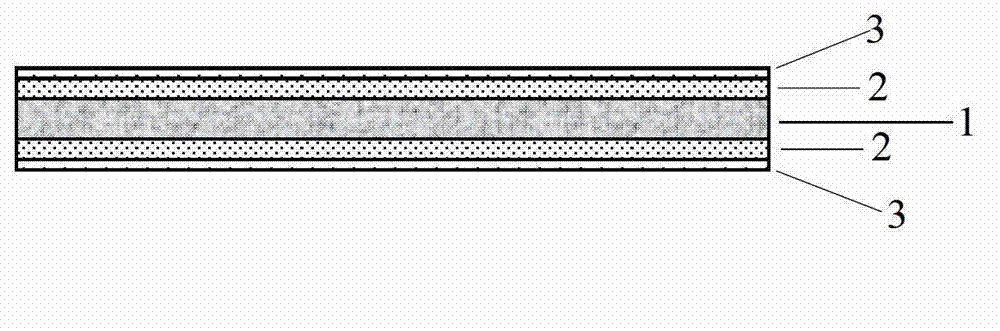

Embodiment 1

[0030] A microporous membrane was prepared according to the method of the comparative example, that is, porous inorganic layer+porous base membrane+porous inorganic layer. Immerse the microporous membrane in 20%wt polyethylene wax emulsion for 5 seconds, then take it out and dry it in an oven at 50°C for 20 minutes to obtain the porous closing layer + porous inorganic layer + porous base film + porous inorganic layer + porous The composite battery separator of the shutdown layer, the porous shutdown layer sandwiches the porous inorganic layer between the porous shutdown layer and the porous base film, wherein the polyethylene wax coating on each surface, that is, the thickness of the porous shutdown layer is 3 μm, the composite battery separator of this example The total thickness is 30 μm, with a Gurley value of about 400, the shutdown temperature is 100°C, and the Gurley value is stable above 2000 when the temperature rises to 105°C.

[0031] During the process of using it a...

Embodiment 2

[0033] The microporous membrane was prepared according to the method of the comparative example, that is, porous inorganic layer+porous base film+porous inorganic layer, and the binder of the inorganic particle slurry was replaced with polyacrylonitrile, and the rest were the same as the comparative example. Immerse the prepared microporous membrane in 20%wt oxidized polyethylene wax emulsion for 5 seconds, then take it out and dry it in an oven at 50°C for 20 minutes to obtain the porous closing layer + porous inorganic layer + porous base membrane + porous inorganic layer in this example + A composite battery separator with a porous shutdown layer, wherein the thickness of the polyethylene wax coating on each side, ie the porous shutdown layer, is 3 μm. The total thickness of the composite battery separator in this example is 30 μm, and the Gurley value is 380. After heat treatment at 110° C. for 10 minutes, the Gurley value rises to about 2500, that is, the shutdown temperat...

Embodiment 3

[0035] Prepare the microporous membrane according to the method of the comparative example, i.e. porous inorganic layer+porous base film+porous inorganic layer, and use polymethyl methacrylate to replace polyvinylidene fluoride as the binder of the inorganic particle slurry, and at the same time, use The polyethylene microporous membrane with a porosity of 50% was used as the base membrane instead of the polypropylene microporous membrane, and the rest was the same as the comparative example. Immerse the prepared microporous membrane in 30%wt low-melting polyethylene wax emulsion for 5 seconds, then take it out and dry it in an oven at 40°C for 30 minutes to obtain the porous shut-off layer + porous inorganic layer + porous base membrane + porous inorganic layer+porous shut-off layer composite battery separator, wherein the thickness of the polyethylene wax coating on each side, namely the porous shut-off layer, is 3 μm. The total thickness of the composite battery separator i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com