Zno-based glass frit composition and aluminum paste composition for back contacts of solar cell using the same

A solar cell and backside contact technology, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve problems such as increased chip breakage rate, low moisture stability, and low battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 17-22

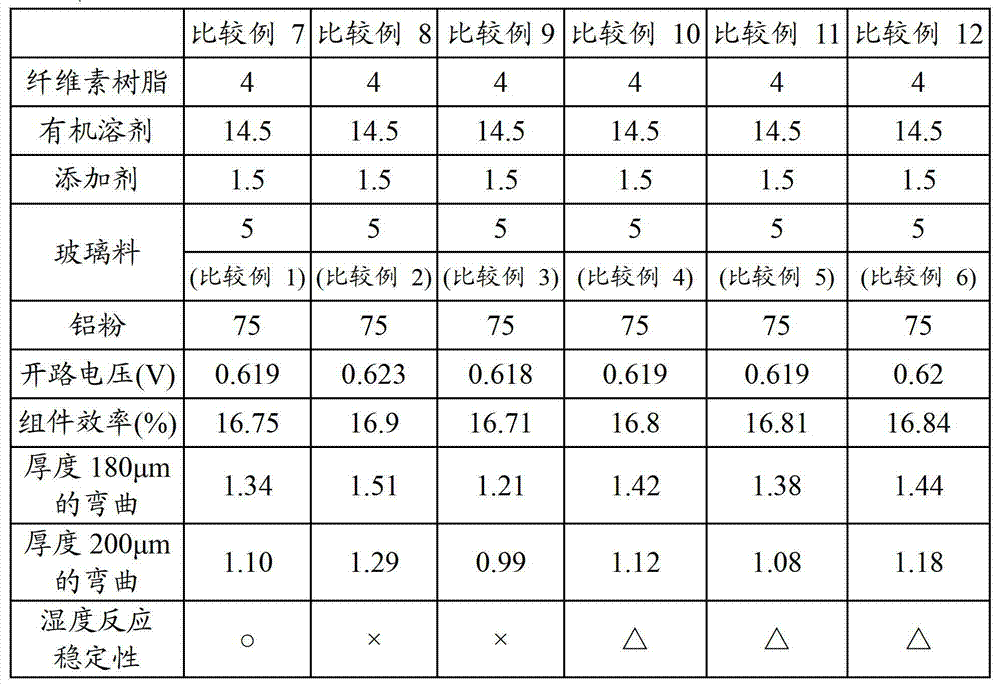

[0093] In order to further evaluate the optimal glass composition of the wafer, the glass frit of Example 3 was used to prepare an aluminum paste composition according to the composition and composition ratio shown in Table 6 below (the unit in Table 6 is wt%). In addition, the same aluminum powder, organic binder, organic solvent, and additives as in Examples 9-16 were used.

[0094] Table 6

[0095]

[0096] As shown in Table 6, although the electrical characteristics of Examples 17-22 using the glass frit of Example 3 of the present invention slightly decreased with the increase of the glass medium content, compared with the comparative examples, the aforementioned examples still had relatively Excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com