Pressure-sensitive adhesive compound, pressure-sensitive adhesive tape, and wafer treatment method

A technology of adhesive and composition, applied in the direction of adhesive heating bonding method, adhesive type, ester copolymer adhesive, etc., which can solve the problems of adhesive burnt adhesion and difficult peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

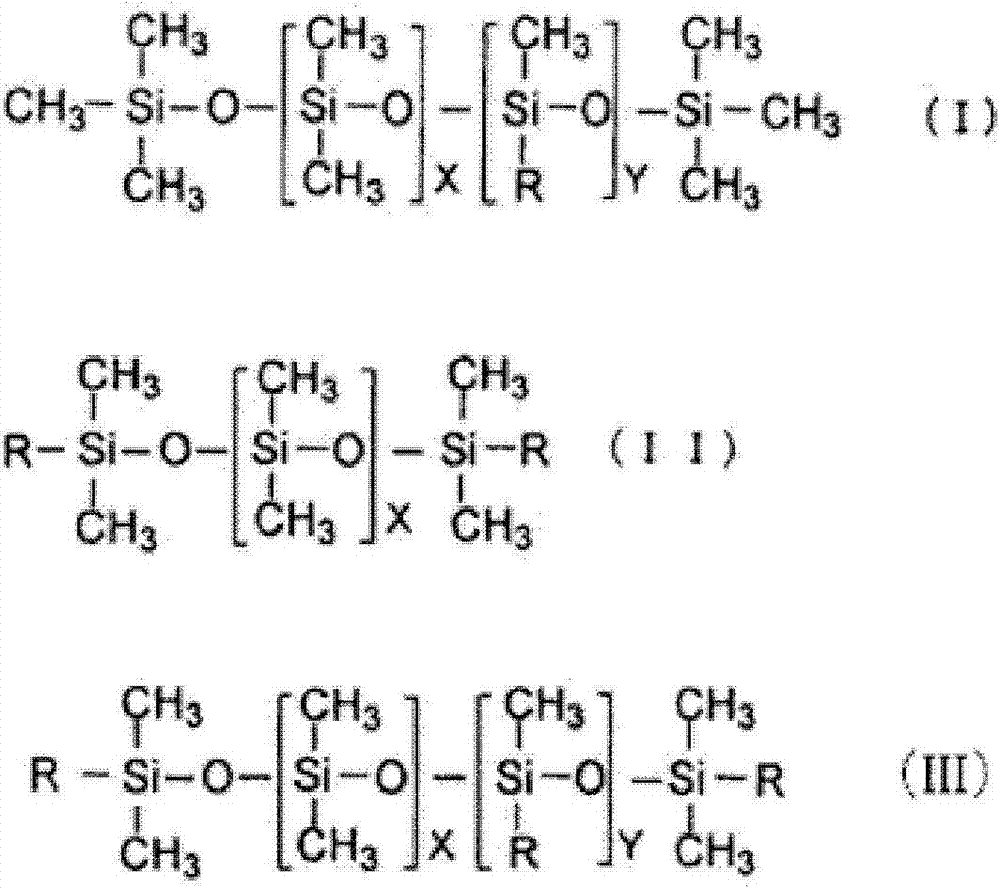

Method used

Image

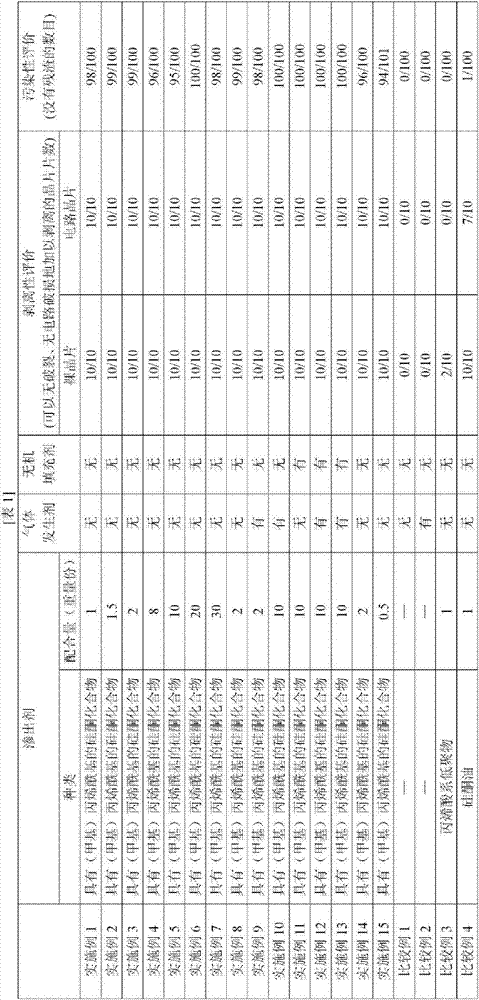

Examples

Embodiment 1

[0071]Prepare a reactor equipped with a thermometer, a stirrer, and a cooling pipe, add 94 parts by weight of 2-ethylhexyl acrylate, 1 part by weight of acrylic acid, 5 parts by weight of 2-hydroxyethyl acrylate, and 0.01 parts by weight of lauryl mercaptan into the reactor , 80 parts by weight of ethyl acetate, and then the reactor was heated to start reflux. Next, 0.01 part by weight of 1,1-bis(tert-hexylperoxy)-3,3,5-trimethylcyclohexane was added as a polymerization initiator into the reactor, and polymerization was initiated under reflux. Then, 0.01 parts by weight of 1,1-bis(tert-hexylperoxide)-3,3,5-trimethylcyclohexane was added 1 hour and 2 hours after the initiation of the polymerization, and further, in After 4 hours from initiation of polymerization, 0.05 parts by weight of t-hexyl peroxypivalate was added to continue the polymerization reaction. Thereafter, 8 hours after the initiation of the polymerization, an acrylic copolymer having a solid content of 55% by w...

Embodiment 2

[0075] Except having made the compounding quantity of the silicone compound which has a (meth)acryloyl group into 1.5 weight part, it carried out similarly to Example 1, and produced the adhesive composition and the adhesive tape.

Embodiment 3

[0077] Except having made the compounding quantity of the silicone compound which has a (meth)acryloyl group into 2 weight part, it carried out similarly to Example 1, and produced the adhesive composition and the adhesive tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com