Special plane slit vortex type desalter filtering device for nuclear power station

A filter device and eddy current technology, which is applied in the field of nuclear power plants, can solve the problems of high processing difficulty, reduced filter life, uneven rigidity distribution, etc., and achieve the effects of improving filtration efficiency, improving installation efficiency, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

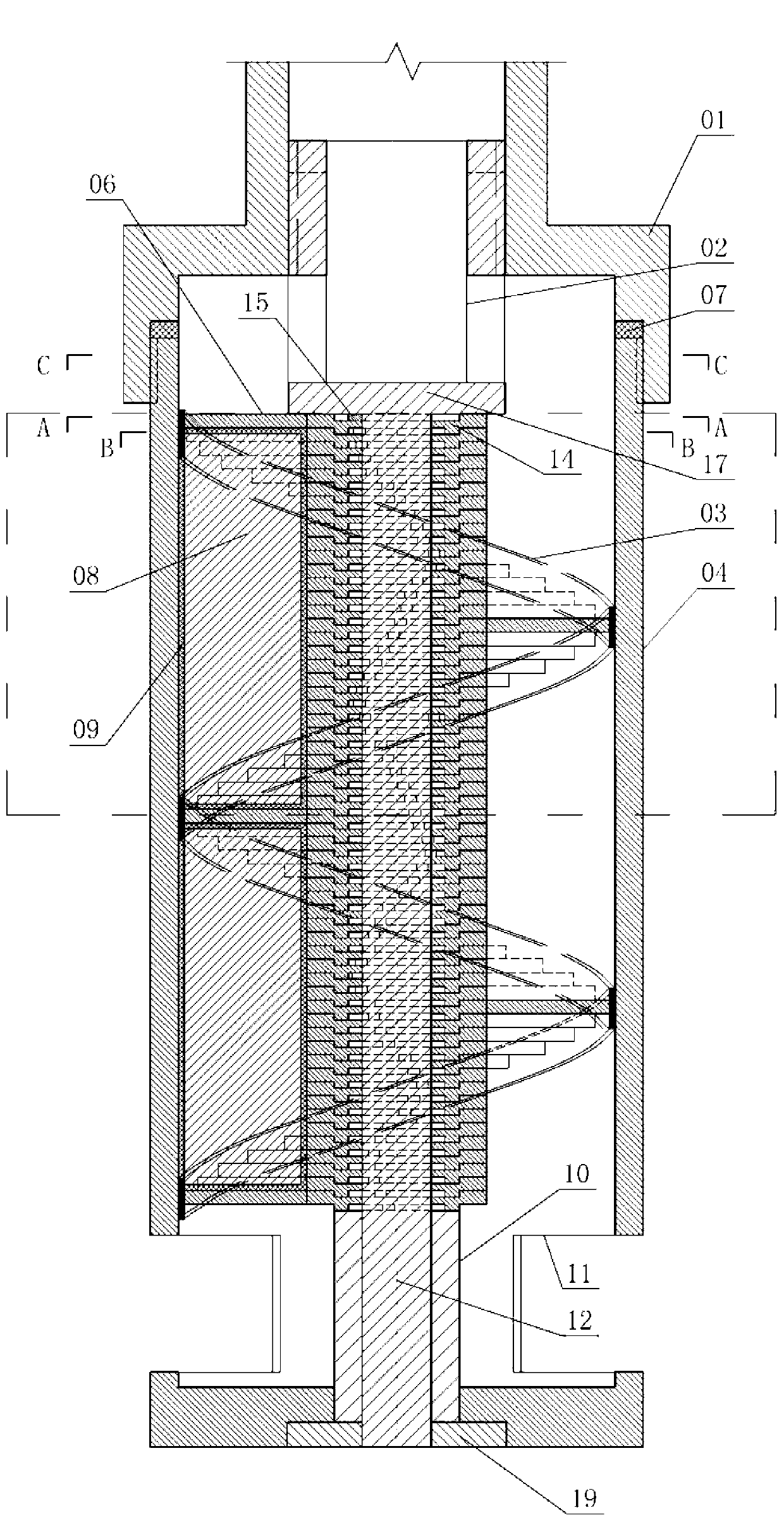

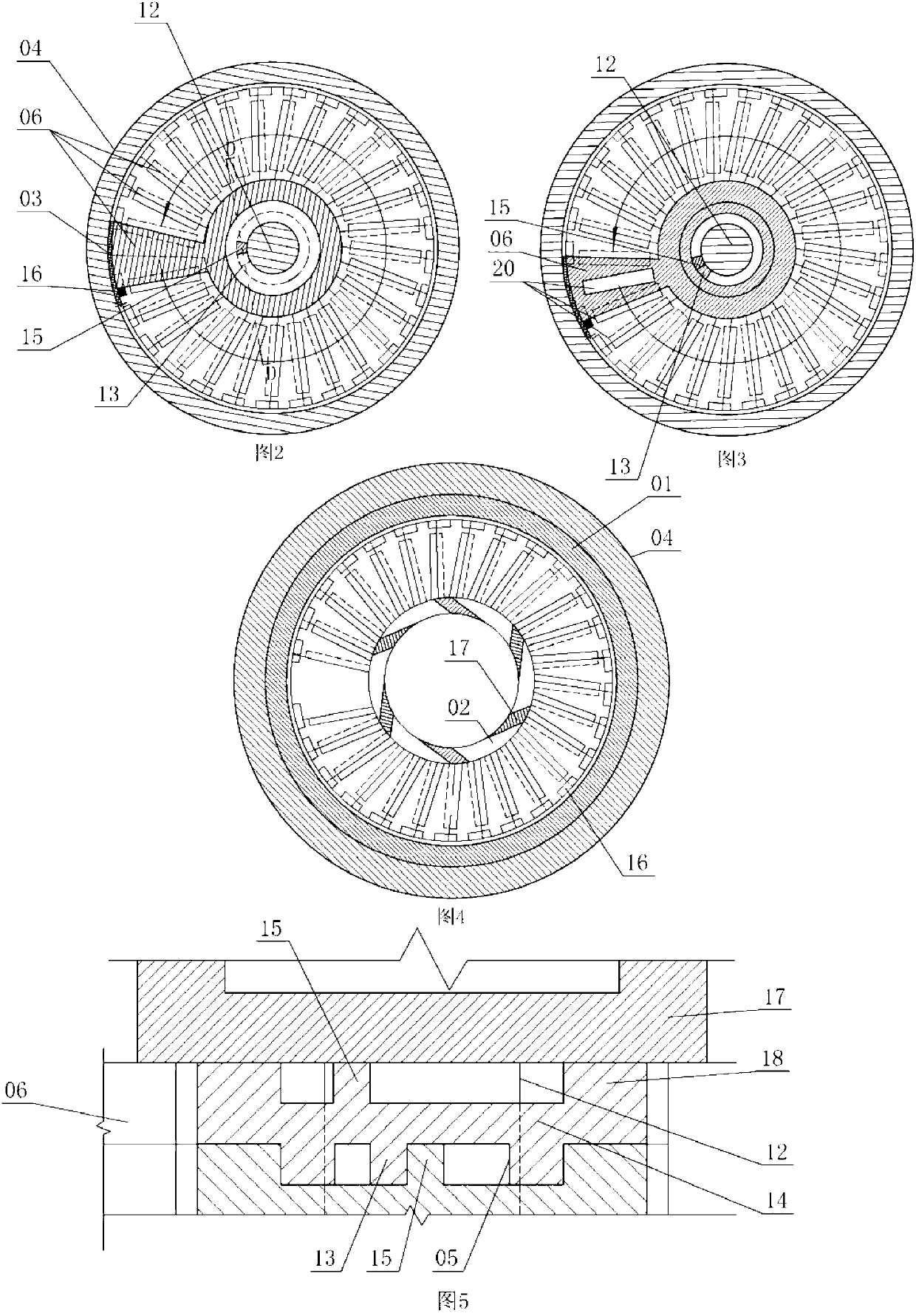

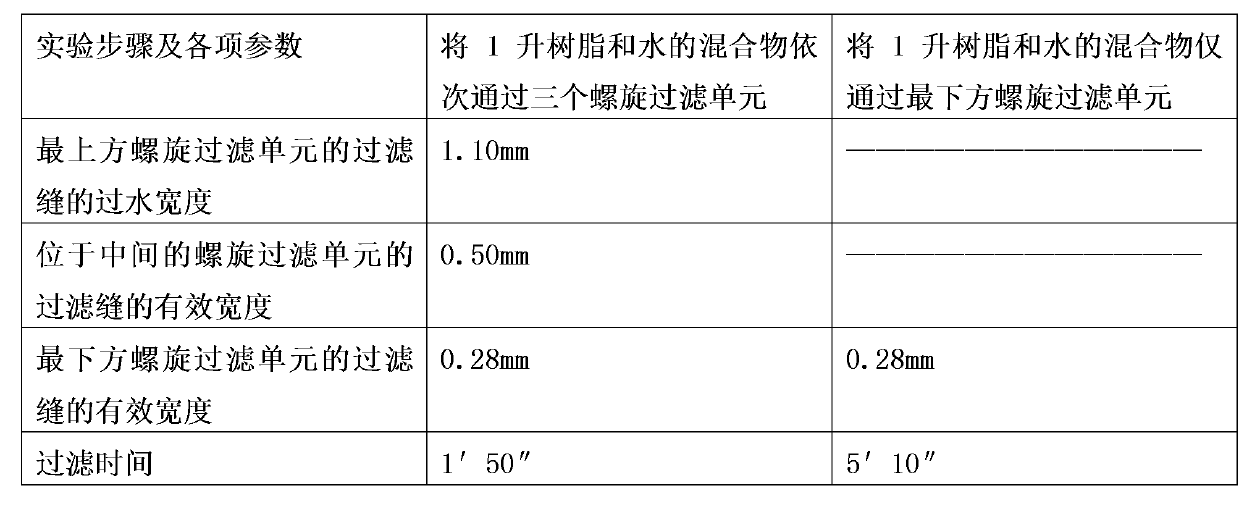

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0058] Special plane slit vortex desalter filter device for nuclear power plants, consisting of connecting pipe 01, water guide port 02, sealing belt 03, filter cartridge 04, sealing ring 07, water baffle 08, sealing edge strip 09, support cylinder 10, water outlet 11 , core post 12, water guide sleeve 17, fastening nut 19 and a plurality of limit sleeve discs.

[0059] Each limit sleeve consists of a lower positioning ring 05, a filter piece 06, a lower limit block 13, a shaft sleeve 14, an upper limit block 15, an elastic clip 16, an upper positioning ring 18 and a filter seam 20. In the cover plate, the shaft center sleeve 14 is a torus, and the edge of the upper surface of the shaft center sleeve 14 has an annular upper positioning ring 18 that is integral with the shaft center sleeve 14, and the bottom surface of the shaft center sleeve 14 has a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com