Non-shaft deflection numerical control waterjet cutter

A water cutting machine, shaftless technology, applied in metal processing and other directions, can solve the problems of low production efficiency and inability to reflect the superiority of water cutting, and achieve the effects of simple structure, widening processing range, and improving processing accuracy and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

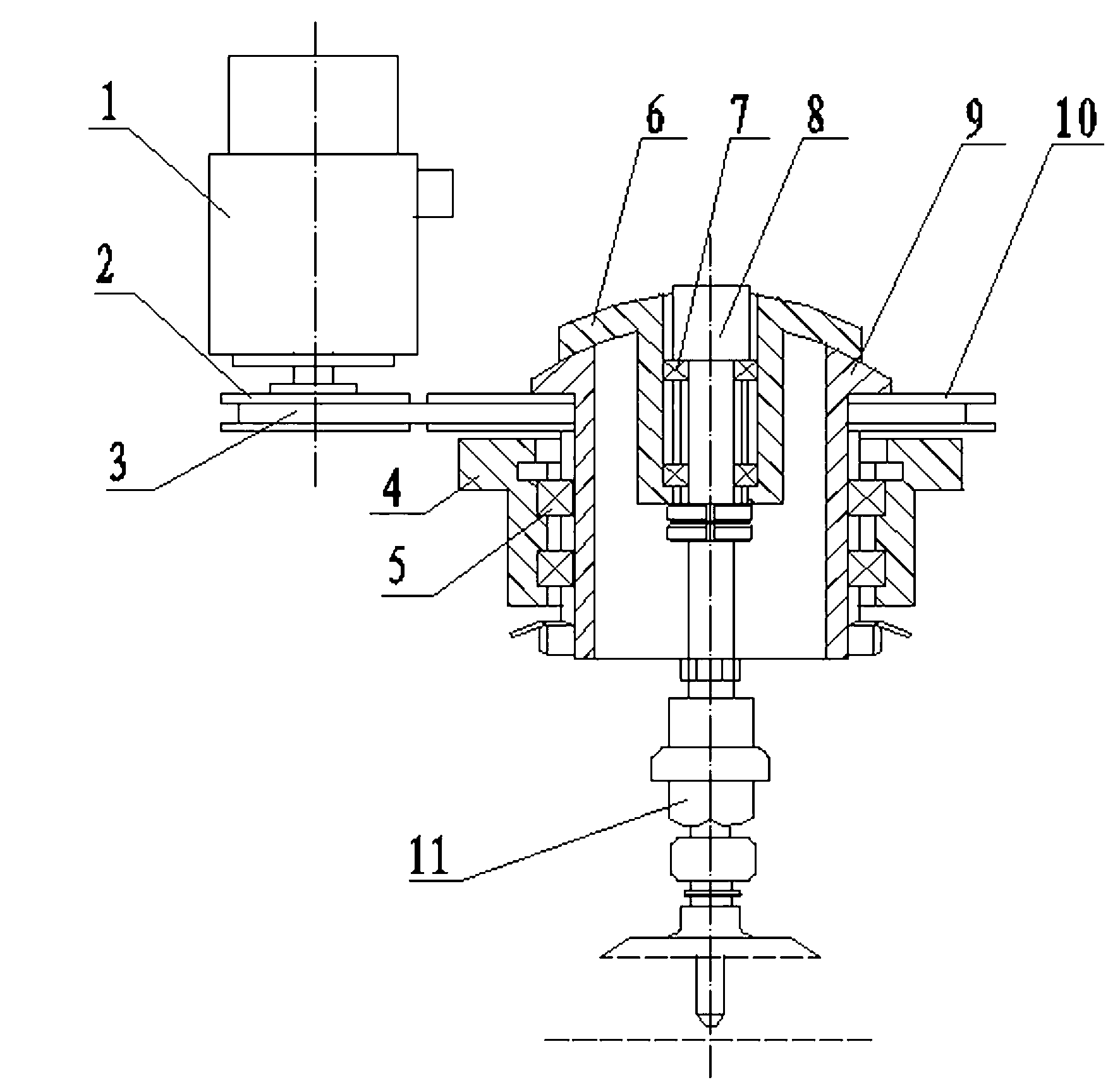

[0010] Shaftless yaw CNC waterjet cutting machine, including yaw servo motor 1, cutter head body 11, bearing seat 4, driving pulley 2, driven pulley 10, upper sliding plate 6, lower sliding plate 9, cutter head connecting rod 8. The output shaft of the yaw servo motor 1 is equipped with a driving pulley 2, and the lower sliding plate 9 is equipped with a driven pulley 10. The driving pulley 2 and the driven pulley 10 are connected with a synchronous toothed belt 3, and the lower slide The plate 9 is installed on the bearing seat 4 fixedly connected with the vertical lifting shaft of the water jet through the bearing 5, the upper sliding plate 6 is placed on the lower sliding plate 9 and slidingly connected, the lower end of the cutter head connecting rod 8 is connected to the cutter head body 11, and the upper end passes through the bearing 7 is contained on the upper sliding plate 6. The upper sliding plate 6 is set as a concave arc surface, and the lower sliding plate 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com