Technology for spraying Babbitt metal to bearing bush

A babbitt alloy and bearing bush technology, which is applied in the field of the bearing bush spraying babbitt alloy process, can solve the problems of reducing the performance of the babbitt alloy itself, affecting the safe operation and life of the equipment, poor bonding strength between the babbitt alloy and the bearing bush, etc. The effect of extended runs, consistent strength, and improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

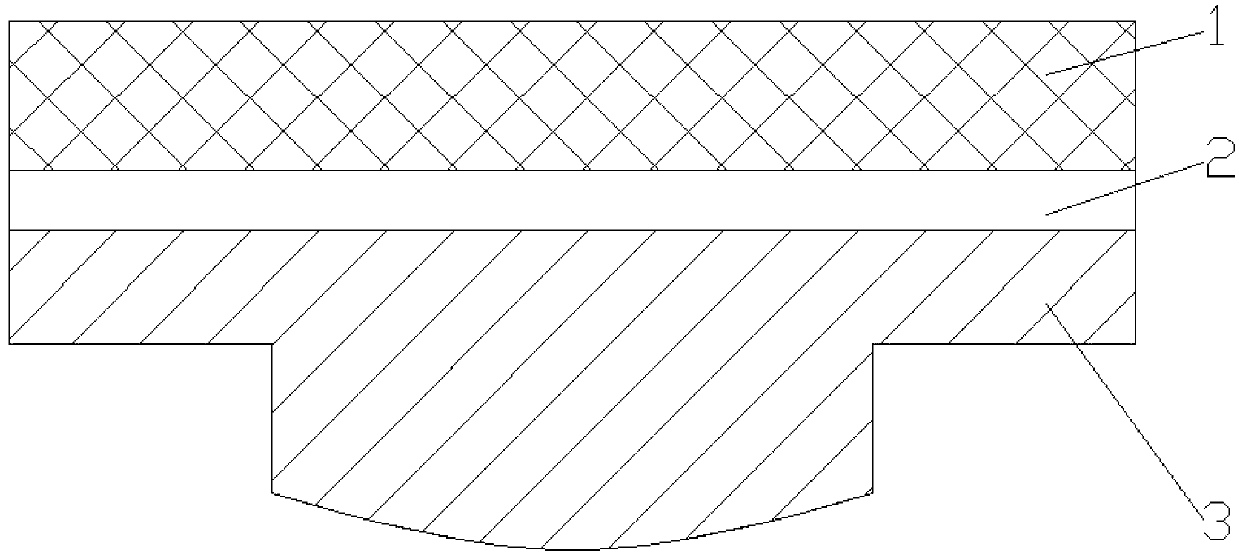

[0023] The process of spraying Babbitt alloy on the bearing bush includes the following steps:

[0024] The bearing bush 3 is heated to 860 degrees Celsius and kept at a constant temperature for 8 hours, and the high temperature is used to remove stress and prevent the bearing bush 3 from deforming.

[0025] Stress Removal After the bearing bush 3 is cooled naturally, the bearing bush 3 is subjected to rough turning, and then the bearing bush 3 is heated to 800 degrees Celsius and kept at a constant temperature for 8 hours, and the hydrogen element is separated from the bearing bush 3 by using high temperature.

[0026] After the dehydrogenation treatment is completed, the bearing bush 3 is naturally cooled, and then the bearing bush 3 is subjected to finishing machining, so that the roughness of the joint surface between the inner hole of the bearing bush 3 and the babbitt alloy reaches 3.2 microns.

[0027] After the finish turning of the bearing bush 3 is completed, the sur...

Embodiment 2

[0031] The process of spraying Babbitt alloy on the bearing bush includes the following steps:

[0032] The bearing bush 3 is heated to 750 degrees centigrade and kept at a constant temperature for 12 hours, and the high temperature is used to remove stress and prevent the bearing bush 3 from deforming.

[0033] Stress removal After the bearing bush 3 is naturally cooled, the bearing bush 3 is subjected to rough turning, and then the bearing bush 3 is heated to 900 degrees Celsius and kept at a constant temperature for 6 hours, and the hydrogen element is separated from the bearing bush 3 by using high temperature.

[0034] After the dehydrogenation treatment is completed, the bearing bush 3 is naturally cooled, and then the bearing bush 3 is subjected to finishing machining, so that the roughness of the bonding surface between the inner hole of the bearing bush 3 and the babbitt alloy reaches 3.4 microns.

[0035] After the finish turning of the bearing bush 3 is completed, t...

Embodiment 3

[0039] The process of spraying Babbitt alloy on the bearing bush includes the following steps:

[0040] The bearing bush 3 is heated to 800 degrees Celsius and kept at a constant temperature for 10 hours, and the high temperature is used to remove stress and prevent the bearing bush 3 from deforming.

[0041] Stress removal After the bearing bush 3 is naturally cooled, the bearing bush 3 is subjected to rough turning, and then the bearing bush 3 is heated to 850 degrees Celsius and kept at a constant temperature for 7 hours, and the hydrogen element is separated from the bearing bush 3 by using high temperature.

[0042] After the dehydrogenation treatment is completed, the bearing bush 3 is naturally cooled, and then the bearing bush 3 is subjected to finishing machining, so that the roughness of the joint surface of the inner hole of the bearing bush 3 and the babbitt alloy reaches 3.0 microns.

[0043] After the finish turning of the bearing bush 3 is completed, the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com