Gear machining surface topography analytical method based on gear machining simulation model

A technology of simulation model and analysis method, applied in the direction of measuring devices, instruments, etc., can solve problems such as synchronous motion error, single kinematic relationship between grinding wheel and workpiece, complex processing motion mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

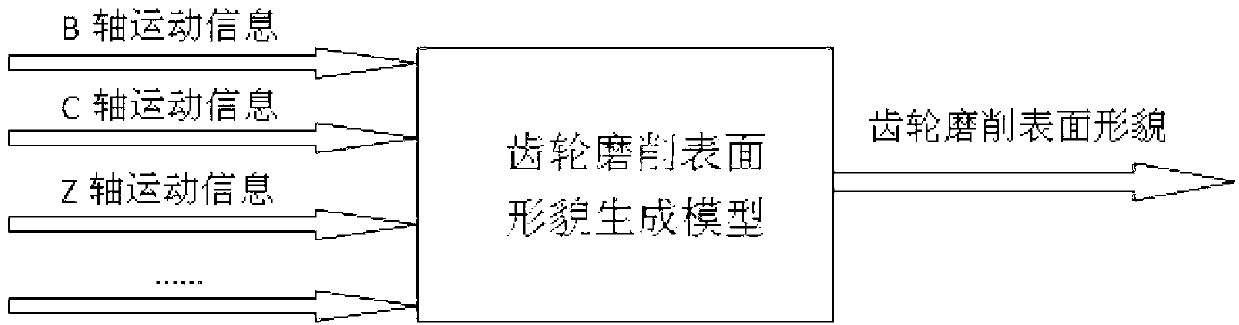

[0067] see figure 1 , a gear machining surface topography analysis method based on a gear machining simulation model, is characterized in that, comprising the following steps:

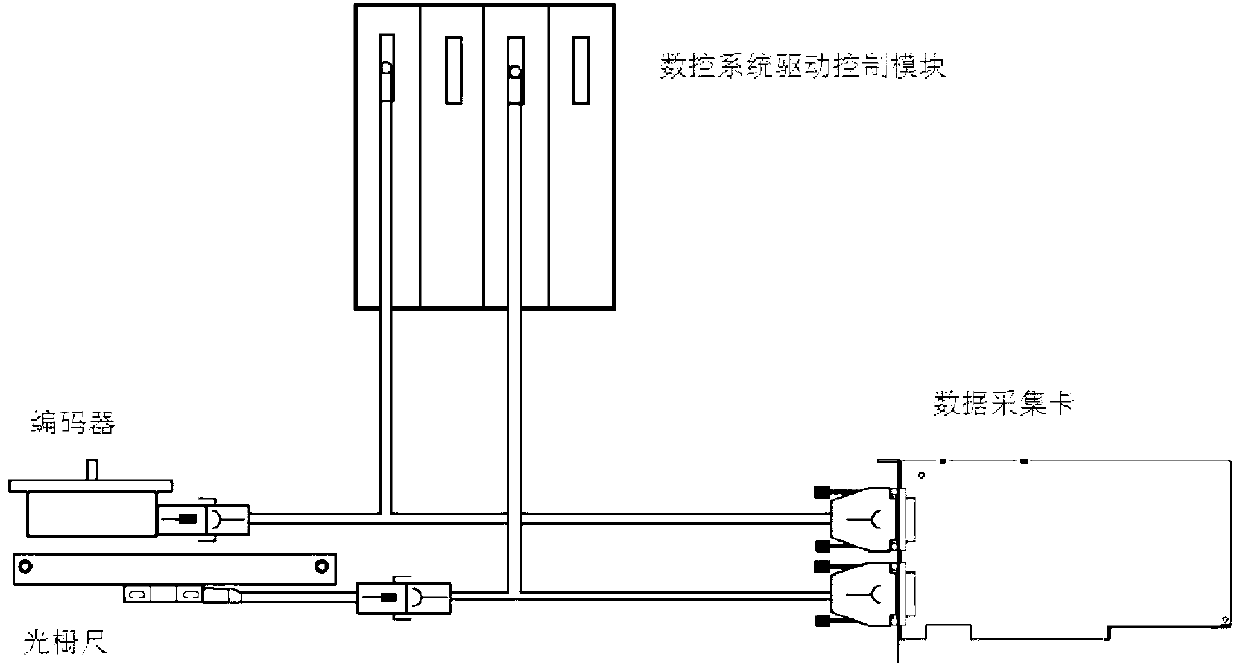

[0068] The gear machining simulation model is established, and then the motion information of the grinding shaft during the gear machining process is input into the gear machining simulation model to obtain the gear precision curve and surface micro-morphology after grinding.

[0069] The gear processing simulation model is established as follows:

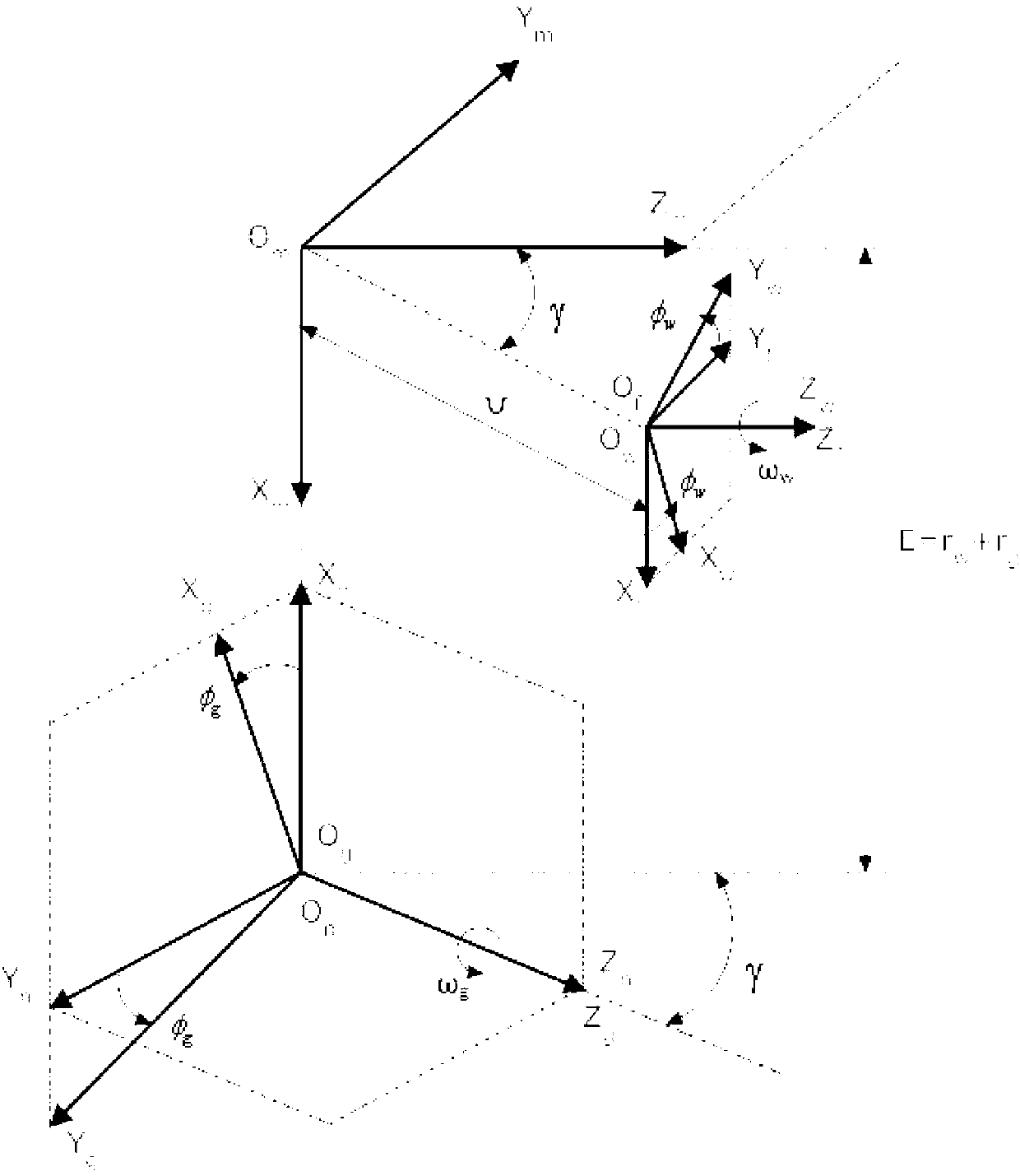

[0070] established as figure 2 The Cartesian coordinate system shown. S m and S n are two fixed coordinate systems, S w , S g Two moving coordinate systems fixedly connected with the worm grinding wheel and the processing gear respectively, S w , S g are two movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com