Techniques for plasma processing a substrate

A plasma and substrate processing technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve problems such as unacceptable, affecting process steps, and doping non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

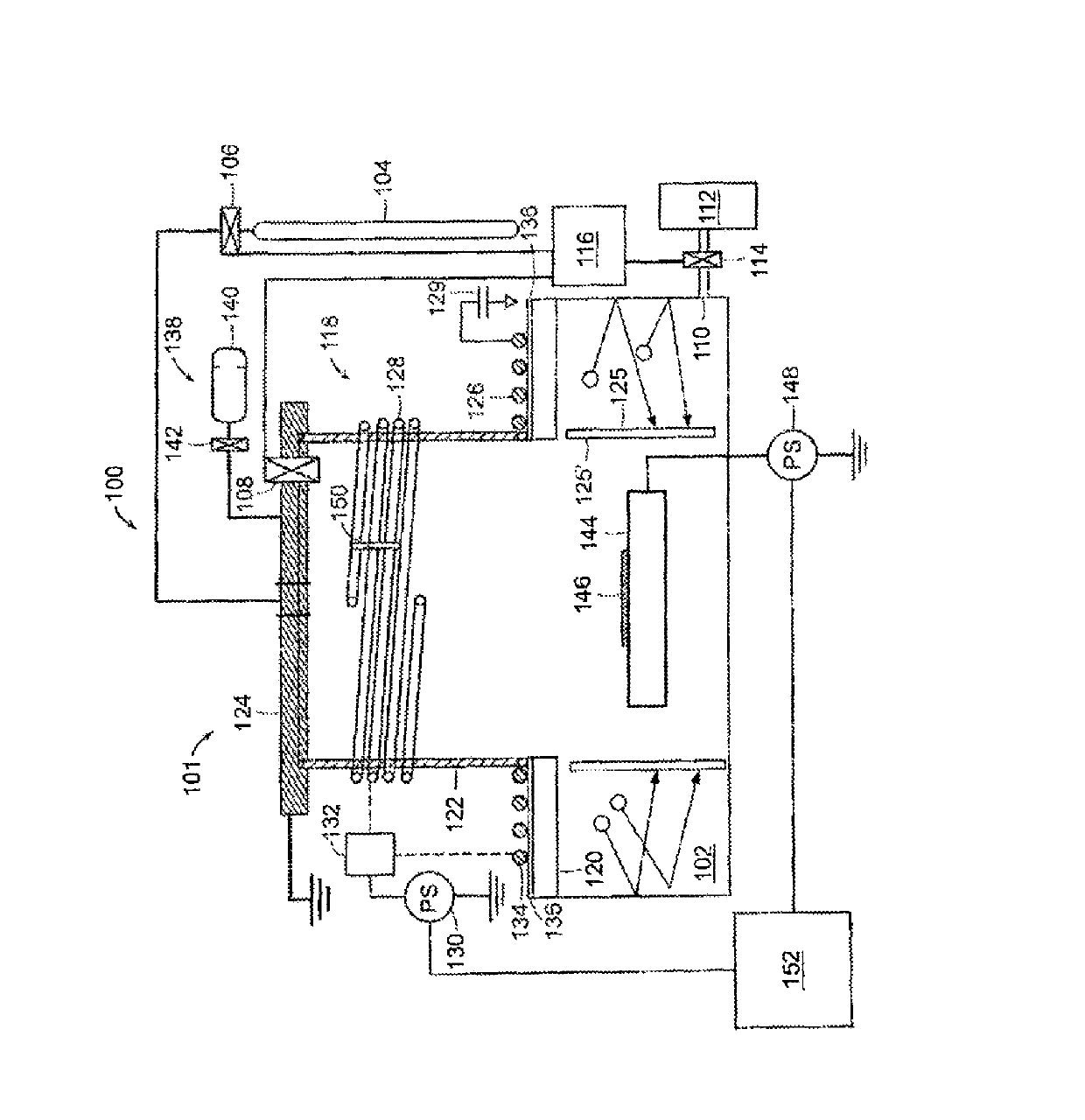

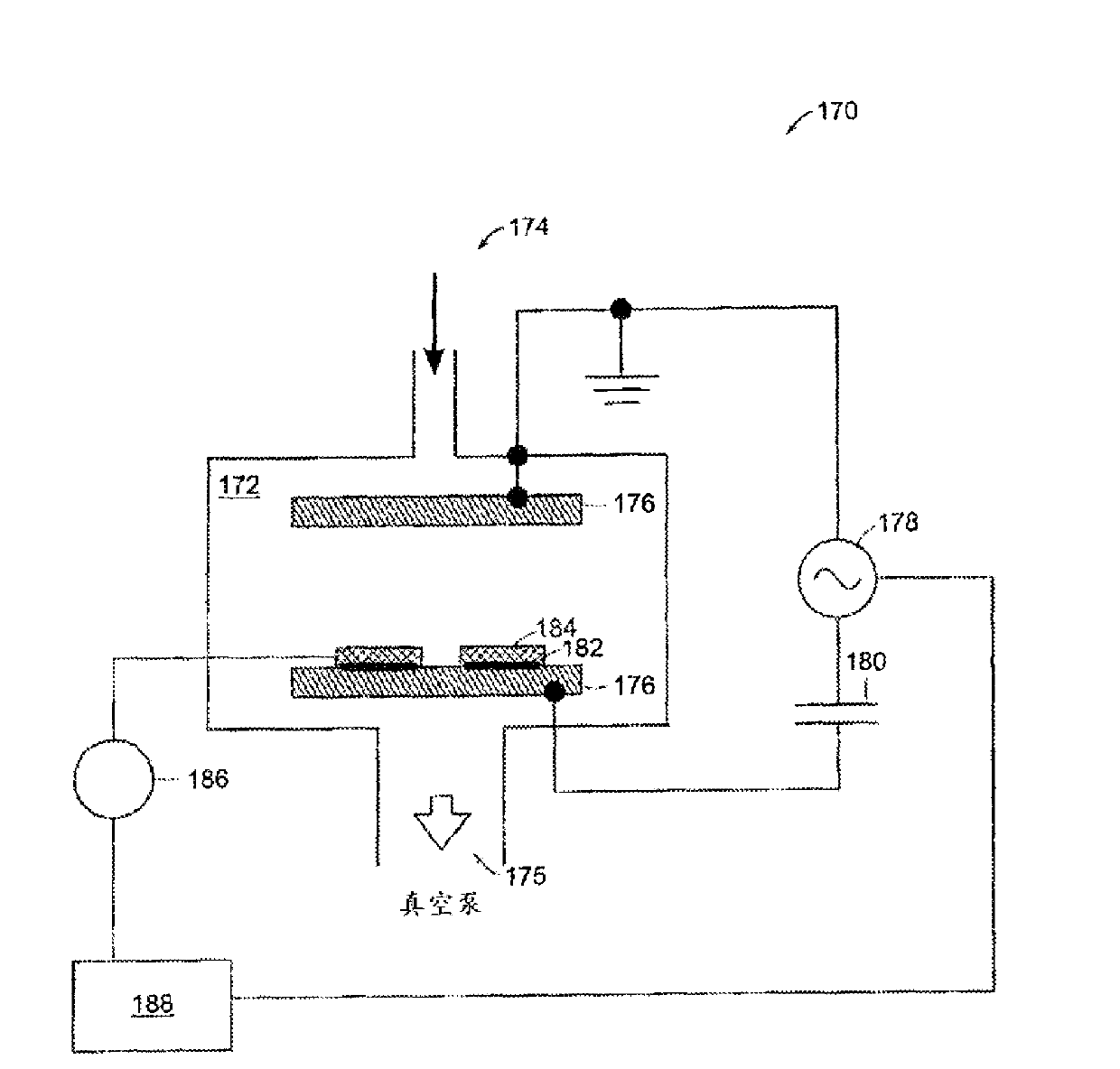

[0048] Several embodiments of new techniques for processing substrates using plasma-based systems are presented herein. For purposes of clarity and conciseness, processing performed on a substrate may focus on doping, etching, and deposition processes. However, the invention does not exclude other types of treatments including passivation of the substrate surface. Thus, the systems disclosed in this disclosure need not be limited to specific systems (eg, doping systems, etching systems, deposition systems, etc.) that perform specific processes.

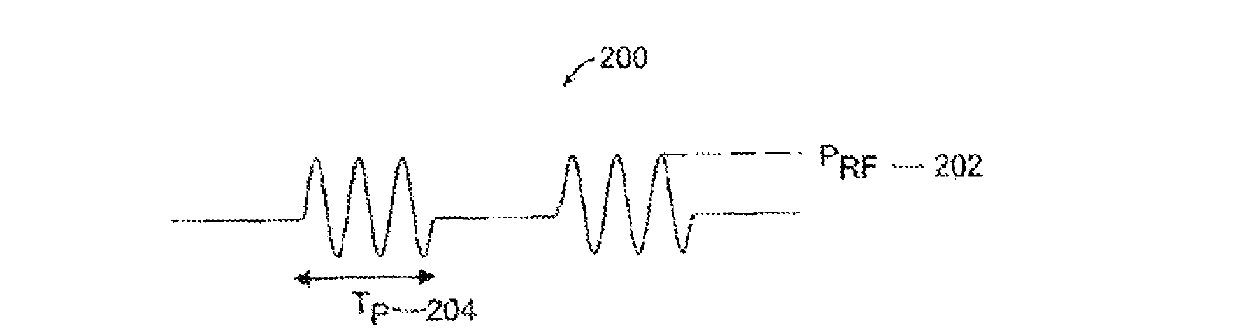

[0049] The systems disclosed herein can include one or more plasma sources for generating plasma. For purposes of clarity and conciseness, the present disclosure will focus on inductively coupled plasma (ICP) sources. However, those skilled in the art will recognize that the present invention does not exclude the inclusion of capacitively coupled plasma (CCP) sources, helicon (helicon) plasma sources, microwave (microwave (MW) plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com