Compound CNC lathe and its power turret

A technology of power turrets and CNC lathes, which is applied in the direction of automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc. It can solve the problems that the functions of milling and drilling cannot be completed, and the machining accuracy of CNC lathes cannot be guaranteed, so as to increase the processing range. , Ensure the processing procedure and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

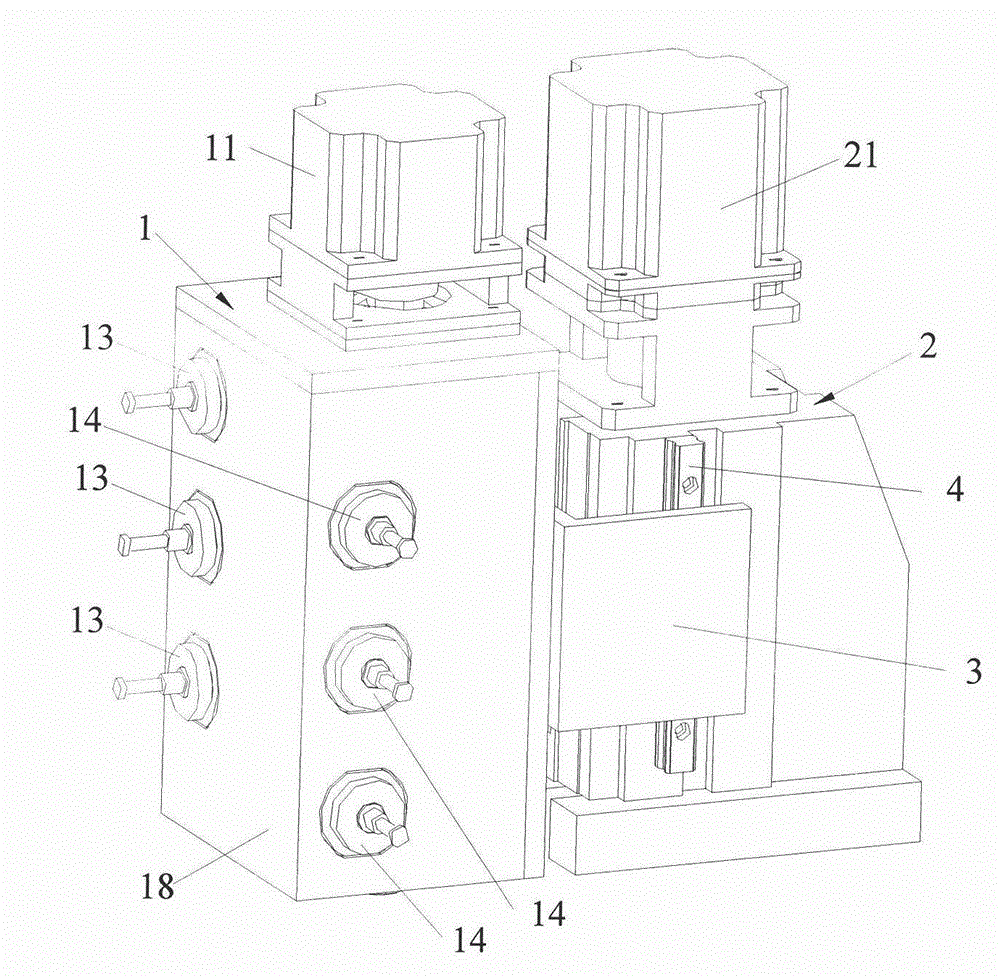

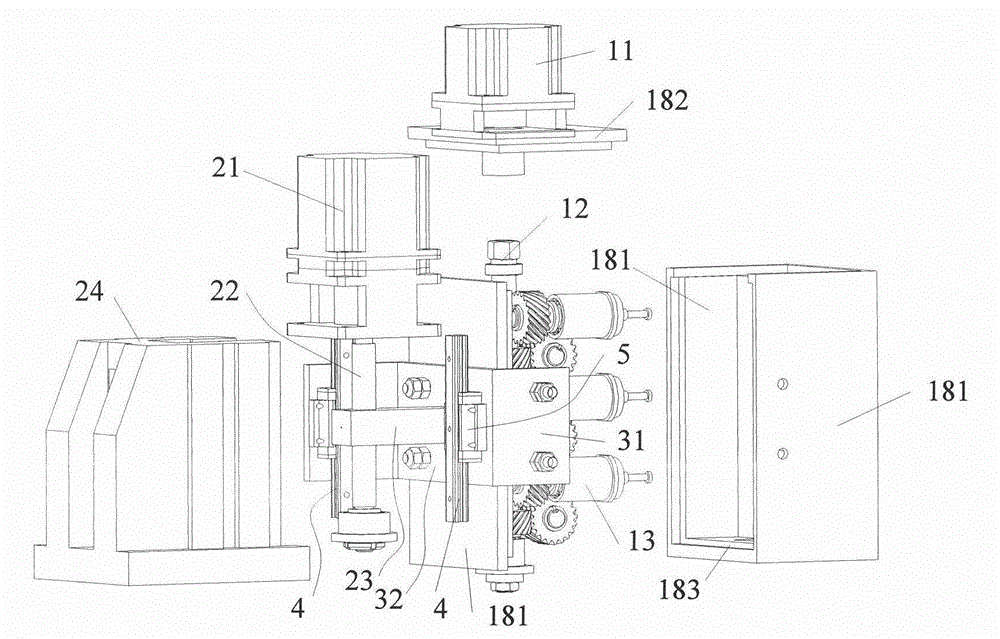

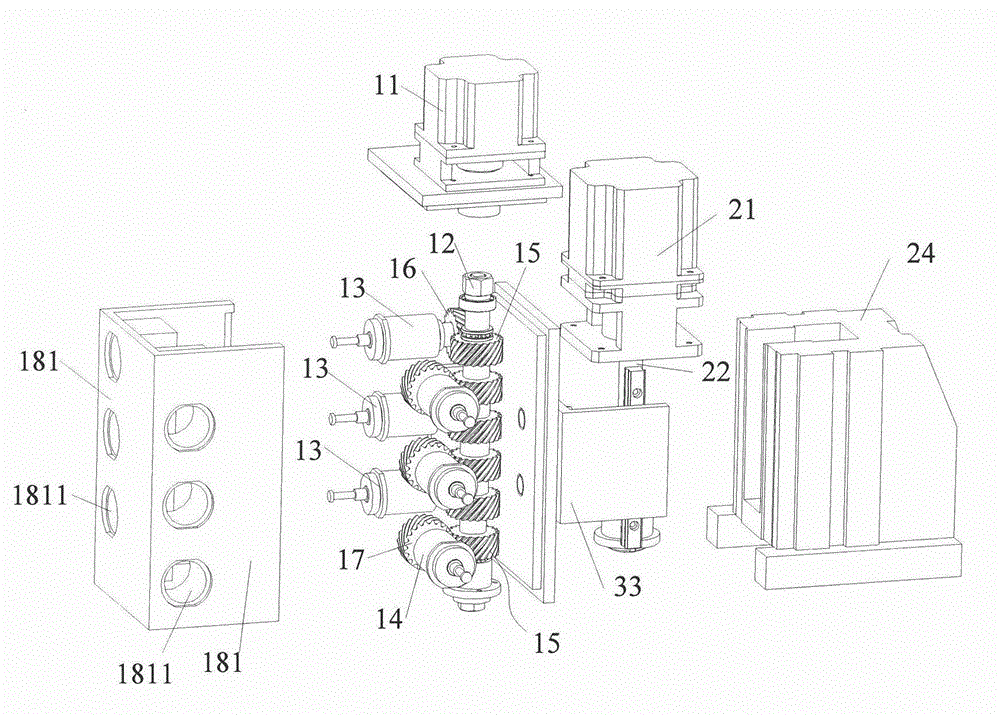

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] see Figure 1 to Figure 3 , in the process of researching and developing the CNC lathe, the technicians of the present invention found that the existing CNC lathe tool holder part can only complete the function of the car, and the functions of milling and drilling should be completed by other machine tools, so that the processing procedures are scattered, especially Especially when processing small and complex parts, the processing accuracy cannot be guaranteed. In order to solve this problem, technicians have developed a power turret. This power turret is suitable for the matching of existing common tool-feeding CNC lathes. After the existing numerical control lathe is equipped with the power turret of the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com