Detecting grinding device

A detection device and grinding technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of reduced work efficiency, low measurement accuracy, and complicated detection devices, and achieve simple structure, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

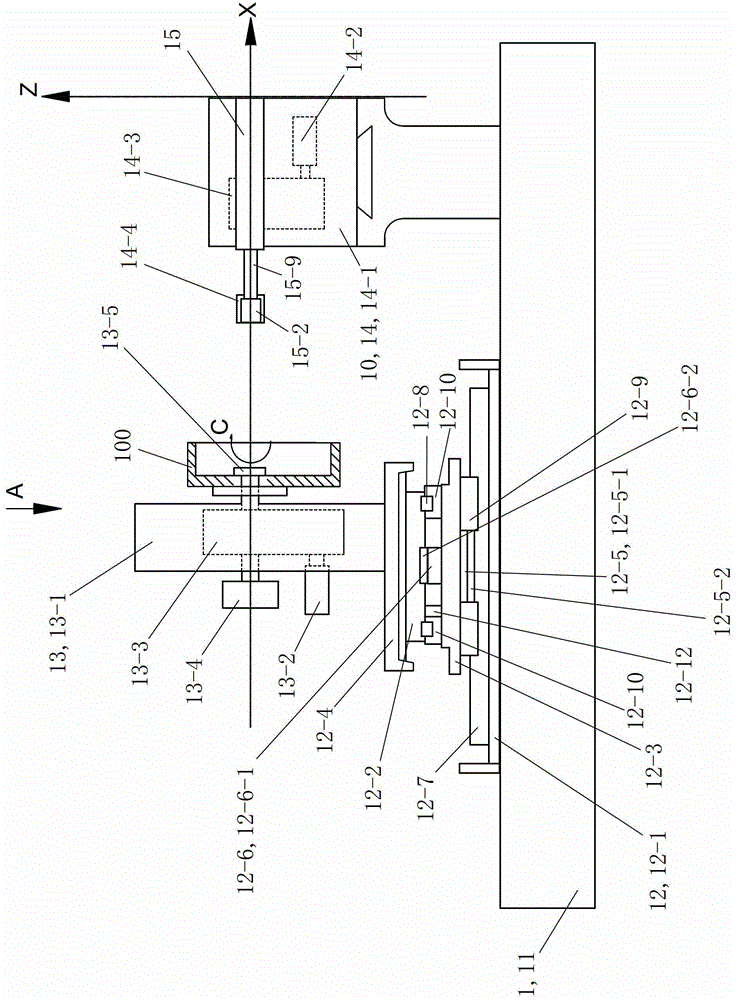

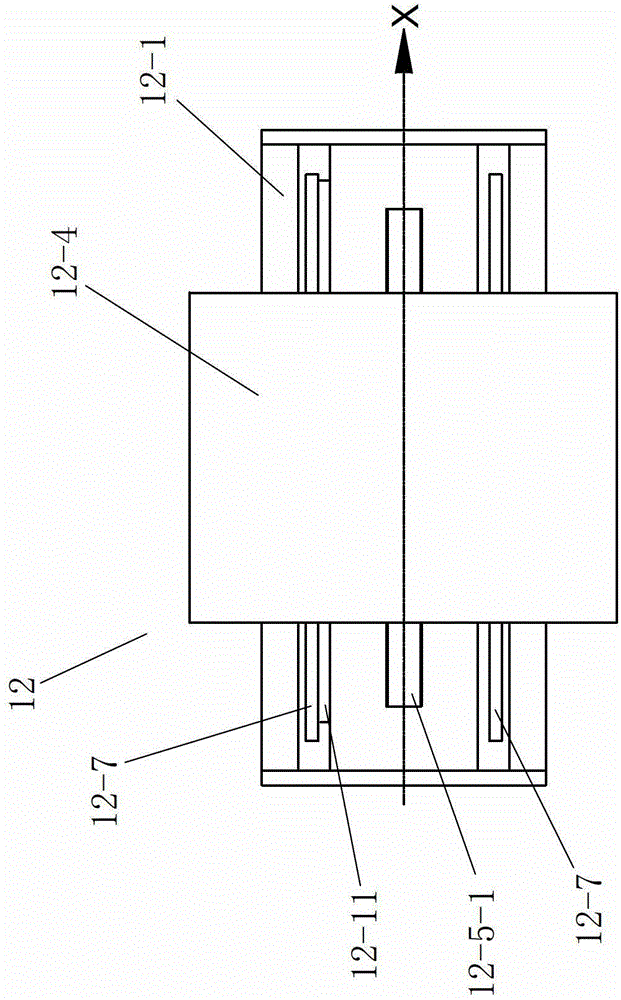

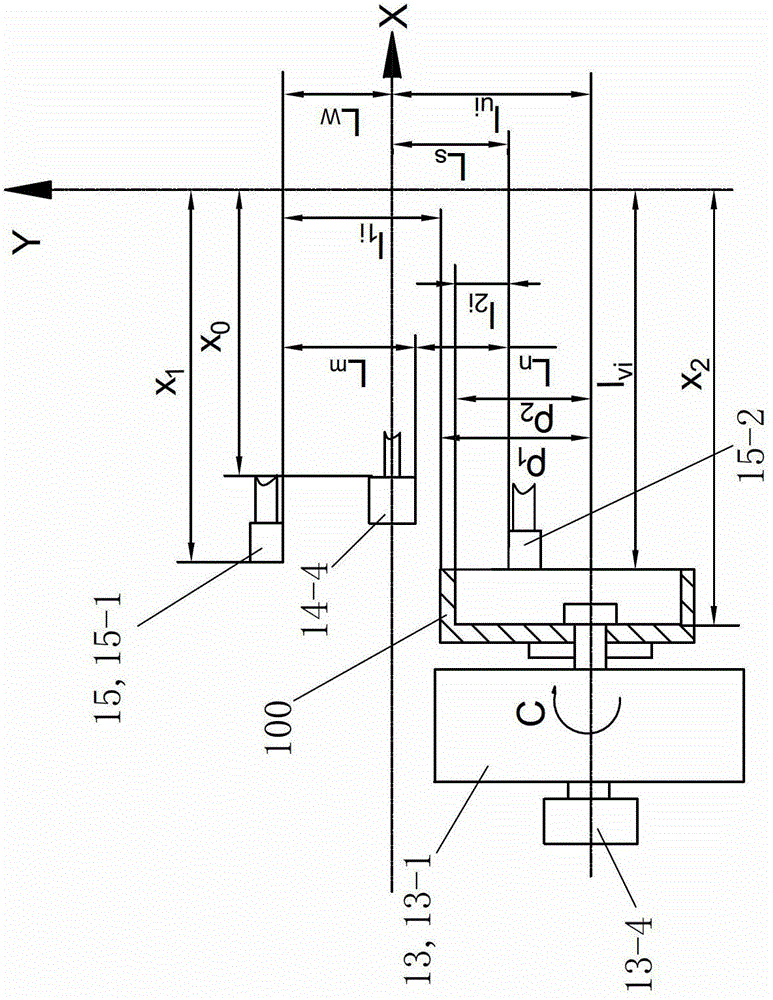

[0035] See figure 1 , image 3 , Figure 5 and Figure 6 , The detection grinding device 10 includes a grinding mechanism 14 and an online detection device 15 . The detection grinding device 10 is controlled by the control system of the corresponding cam processing equipment. The grinding mechanism 14 includes a grinding table 14-1, a second AC servo motor 14-2, a speed control box 14-3 and a grinding wheel grinding head 14-4. The speed control box 14-3 is fixed on the grinding table 14-1, and the output shaft of the speed control box 14-3 is arranged along the X direction and faces to the left. The emery wheel grinding head 14-4 is fixedly arranged on the left end of the output shaft of the speed regulating box 14-3. The second AC servo motor 14-2 is fixedly arranged on the grinding table 14-1, the second AC servo motor 14-2 is connected with the input shaft of the speed control box 14-3, and is driven by the second AC servo motor 14-2 The speed regulating box 14-3 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com