Grinding roller shock absorption grinding wheel adjustable in hardness

A rolling and vibration-absorbing technology, which is applied in the field of abrasives and abrasive tools, can solve the problems of fixedness and poor versatility, and achieve the effects of reducing the hardness of the grinding wheel, simple production process, and reasonable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

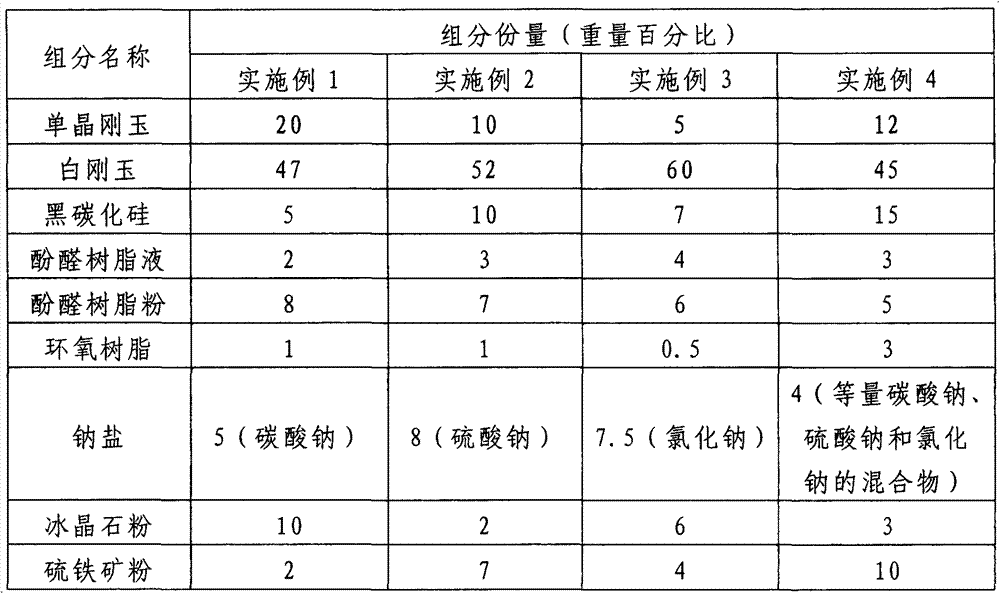

[0021] Grinding roller vibration-absorbing grinding wheel with adjustable hardness, its components are measured by weight percentage as follows: white corundum 45% to 60%, single crystal corundum 5% to 20%, black silicon carbide 5% to 15%, phenolic resin solution 2% ~4%, phenolic resin powder 5%~8%, epoxy resin liquid 0.5%~3%, sodium salt 4%~8%, cryolite powder 2%~10% and pyrite powder 2%~10%.

[0022] The present invention is verified below by different examples of adjusting the component portions.

[0023] Example of vibration-absorbing grinding wheel for grinding rollers with adjustable hardness Component and component configuration table:

[0024]

[0025] Note: the sodium salt used in embodiment 4 is the mixture of sodium carbonate, sodium sulfate and sodium chloride each accounting for one-third of the amount.

[0026] The components of the above examples have been adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com