Grinder grinding wheel numerical control production line

A production line and grinding wheel technology, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of turning product quality, parameter index deviation, low production efficiency, etc., to ensure product quality and avoid subjective awareness. Deviation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

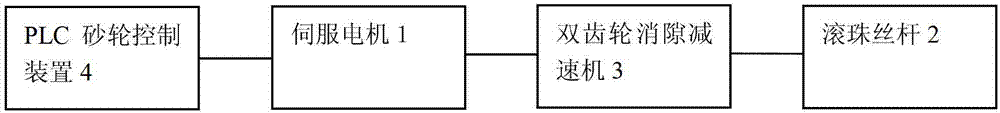

[0011] The present invention relates to a kind of grinding machine grinding wheel numerical control production line, such as figure 1 As shown, it includes a servo motor 1 providing a power source and a ball screw 2 driven by the servo motor, wherein the power output end of the servo motor 1 is connected to the ball screw 2 through a double-gear anti-backlash reducer 3 . The servo motor 1 is also connected with a PLC grinding wheel control device 4 , and the signal output end of the PLC grinding wheel control device 4 is connected with the signal input end of the servo motor 2 .

[0012] Through the addition and use of the PLC grinding wheel control device 4, the present invention can realize the automatic progress of the grinding wheel production process, avoid the subjective consciousness deviation caused by manual direct processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com