SBR (sequencing batch reactor) semi-short-distance nitrification process control method

A semi-short-course nitrification and process control technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of uncontrollable ratio of nitrite and ammonia nitrogen concentration in semi-short-course nitrification effluent , to achieve the effect of strong impact load resistance and convenient management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

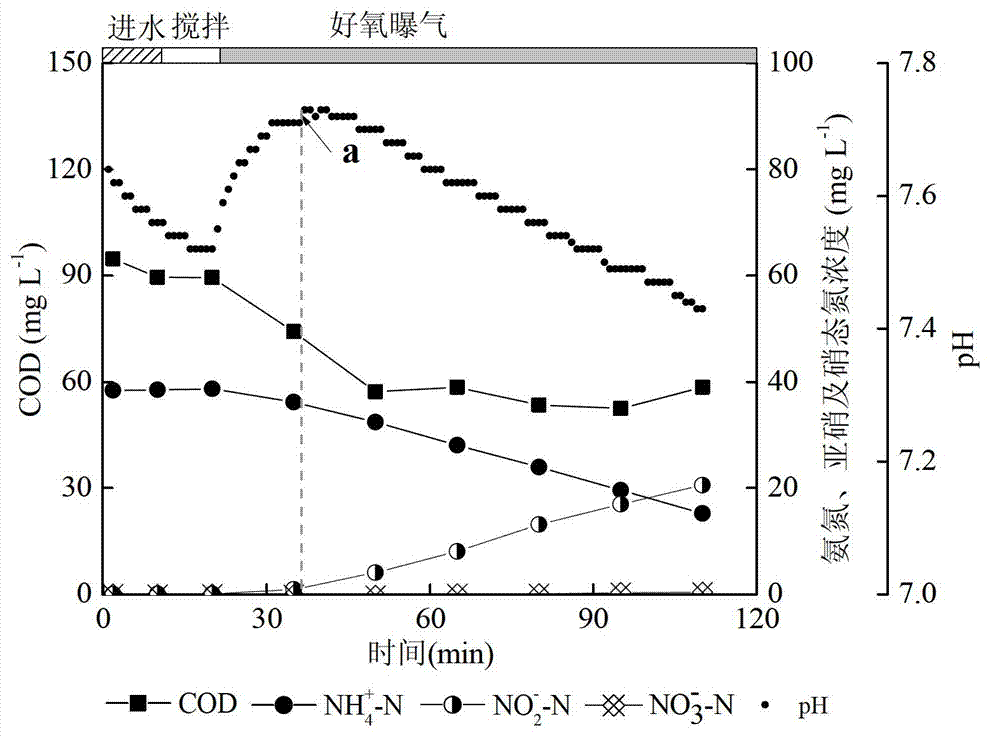

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

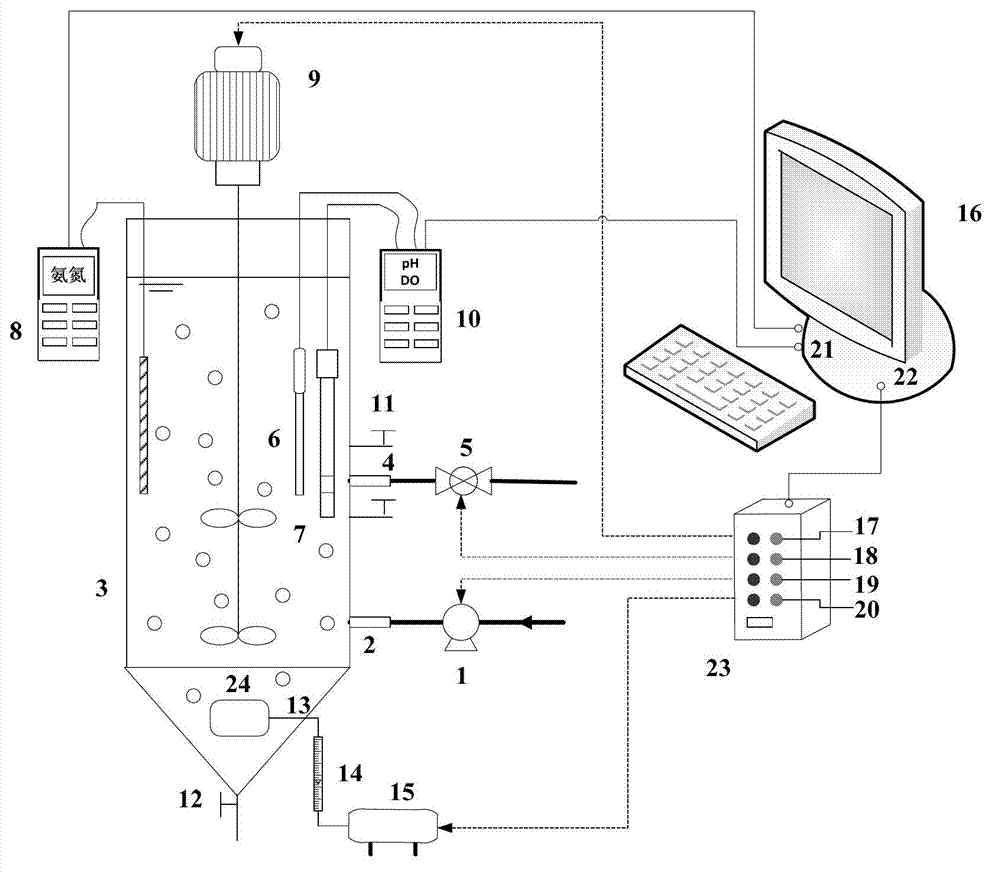

[0036] Such as image 3 As shown in the structural diagram, the water inlet pump 1 is connected to the SBR reactor 3 through the water inlet pipe 2; the water outlet pipe 4 is provided with the water outlet valve 5; It is equipped with drainage pipe 11 and mud discharge pipe 12;

[0037]SBR reactor built-in pH and DO measuring instrument 10 (connected with pH sensor 6 and dissolved oxygen concentration DO sensor 7 through wires), ammonia nitrogen measuring instrument 8, stirrer 9; pH and DO measuring instrument 10 and ammonia nitrogen measuring instrument 8 are connected through wires The data signal input interface 21 of computer 16 is connected, and the data signal output interface 22 of computer is connected process controller 23 through wire, and the agitation relay 17 of process controller, drainage relay 18, water inlet relay 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com