Pure vegetable oil based polyalcohol and preparation method thereof

An oil-based polyol and pure plant technology, which is applied in the field of pure vegetable oil-based polyol and its preparation, can solve problems that have not been seen yet, and achieve the effects of simple preparation method, rich source of raw materials, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

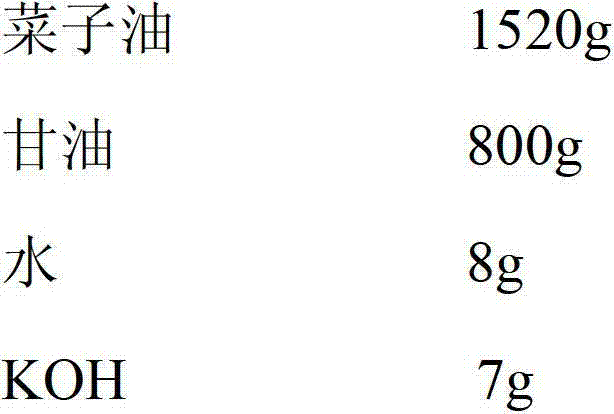

Embodiment 1

[0054]

[0055] The above-mentioned components are fed, and under the protection of nitrogen, the temperature is raised to 240°C for 7 hours (about 110 g of water). Turn off the nitrogen, vacuum, heat up to 260°C and react for 4 hours (about 85 grams of water and some oily substances are produced). After cooling, about 2130g of product is obtained. The hydroxyl value of the product is about 260mgKOH / g.

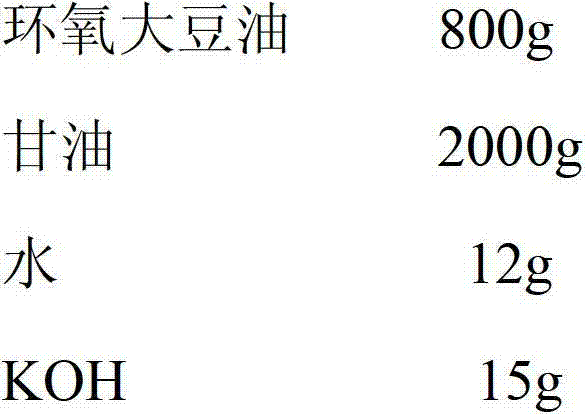

Embodiment 2

[0057]

[0058] The above components (except the epoxy soybean oil) are charged, and the temperature is raised to 250°C for 9 hours under the protection of nitrogen (about 410 grams of water output). Cool slightly, turn off the nitrogen, vacuumize, add epoxy soybean oil, and heat up to 220°C for 3 hours. After cooling, about 2400g of product is obtained. The hydroxyl value of the product is about 460mgKOH / g.

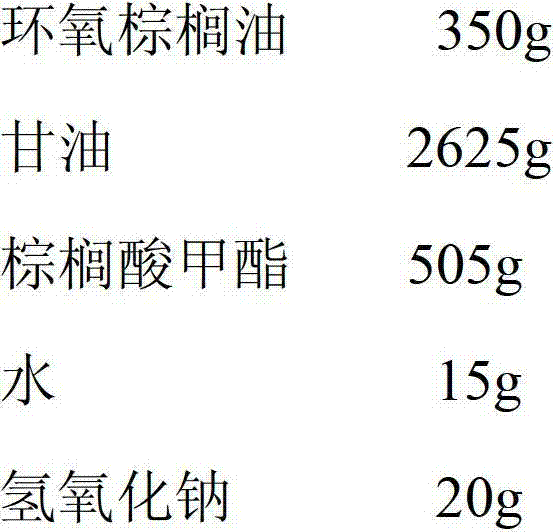

Embodiment 3

[0060] Epoxy Linseed Oil 1600g

[0061] Tetraglycerol 532g

[0062] KOH 1.3g

[0063] Feed the above components, under the protection of nitrogen, heat up to 220°C for 3 hours (turn off the nitrogen, vacuum, heat up to 230°C and react for 3 hours (about 13 grams of water and oily substances). Cool and get The product is about 2120g. The hydroxyl value of the product is about 230mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com