Environment-friendly wallpaper substrate capable of regulating temperature and preparation method thereof

A technology for wallpaper and temperature adjustment, which is applied in the field of materials, can solve the problems of substrate compatibility and stability leakage, etc., and achieve the effects of strong temperature adjustment ability, ingenious process structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

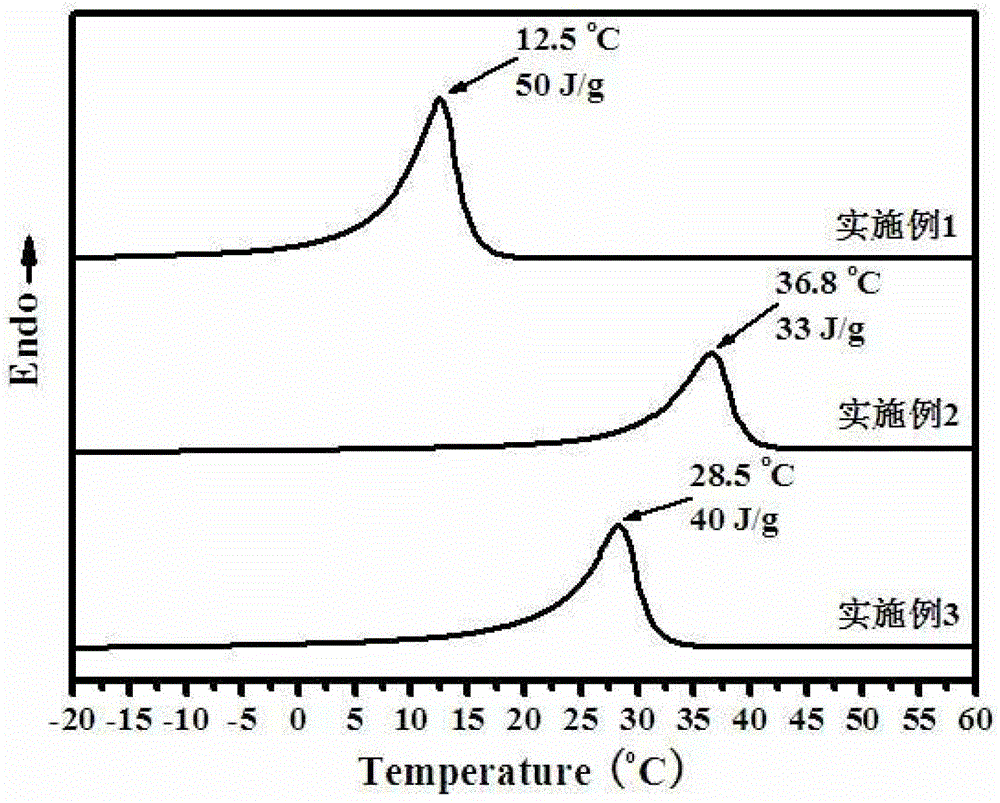

Embodiment 1

[0032] A method for preparing an environment-friendly, temperature-adjustable wallpaper base material is characterized in that it is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0033] (1) Preparation of modified calcium carbonate powder: Weigh 100 parts of the pre-dried calcium carbonate powder through a 2000-mesh sieve, and then weigh 1 part of γ-methacryloxypropyl trimethoxy as the surface treatment agent Add base silane (KH570) into a high-speed mixer that can be heated up, heat up to 80°C and stir at high speed for 120 minutes to obtain modified calcium carbonate powder;

[0034] (2) Preparation of mixed pellets: 25 parts of purified and dried self-synthesized polyether ester copolymer (polyethylene terephthalate-co-polyethylene glycol copolymer, intrinsic viscosity 0.40dL / g The molecular weight of polyethylene glycol is 1000g / mol, and the proportion in the copolymer is 80%. It includes two traditional ...

Embodiment 2

[0038] A method for preparing an environment-friendly, temperature-adjustable wallpaper base material is characterized in that it is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0039](1) Preparation of modified calcium carbonate powder: Weigh 100 parts of the pre-dried calcium carbonate powder through a 1000-mesh sieve, and then weigh 0.7 parts of the surface treatment agent γ-chloropropyltriethoxysilane (KH550 ), add them together into a high-speed mixer that can be heated up, heat up to 100°C and stir at a high speed for 60 minutes, and the modified calcium carbonate powder can be obtained;

[0040] (2) Preparation of mixed pellets: 15 parts of purified and dried self-synthesized polyether ester copolymer (polyethylene terephthalate-co-polyethylene glycol copolymer, intrinsic viscosity 0.50dL / g ; The molecular weight of polyethylene glycol is 10000g / mol, and the proportion in the copolymer is 30%), 85 par...

Embodiment 3

[0044] A method for preparing an environment-friendly, temperature-adjustable wallpaper base material is characterized in that it is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0045] (1) Preparation of modified calcium carbonate powder: 100 parts of the pre-dried calcium carbonate powder were sieved through a 3000-mesh sieve, and then 0.5 parts of isopropyl dioleic acid acyloxy (dioctyl Phosphoric acid acyloxy) titanate (TMC-101), add it into a high-speed mixer that can be heated up, raise the temperature to 120 ° C and stir at a high speed for 30 minutes, and then the modified calcium carbonate powder can be obtained;

[0046] (2) Preparation of mixed pellets: 20 parts of purified and dried self-synthesized polyether ester copolymer (polyethylene terephthalate-co-polyethylene glycol copolymer, intrinsic viscosity 0.65dL / g ; The molecular weight of polyethylene glycol is 4000g / mol, and the proportion in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com