Preparation and application of solvent-free spraying polyurethane pipeline mending coating

A polyurethane and solvent-free technology is applied in the field of preparation of solvent-free spray-type polyurethane pipe patching coatings, which can solve the problems of insignificant effect, high overhaul cost, and difficulty in guaranteeing construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Synthesize 37.5 parts of MDI-50, 37.5 parts of MDI-100, and 25.0 parts of aminoethylaminopropyl polydimethylsiloxane according to the process of the present invention to obtain a prepolymer with an NCO% of 24.5%, which is A components. The R component is composed of 18.7 parts of hydroxyl-terminated cross-linking agent triethanolamine, 156.3 parts of polyoxypropylene ether triol TMN3050, 190 parts of filler ultrafine barium sulfate, 5 parts of water-absorbing agent A3, 0.5 parts of organic tin catalyst T-12, 2.0 parts Composed of defoamer BYK-530, 2.0 parts of anti-settling agent BYK-306 and 1.0 parts of leveling agent BYK-361N. A and R components are sprayed on the surface of the substrate according to 1:2.5 (volume ratio).

Embodiment 2

[0040]Synthesize 41.0 parts of MDI-50, 41.0 parts of MDI-100, and 18.0 parts of aminoethylaminopropyl polydimethylsiloxane according to the process of the present invention to obtain a prepolymer with an NCO% of 27.0%, which is Group A point. The R component is composed of 21.5 parts of hydroxyl-terminated cross-linking agent triethanolamine, 153.5 parts of polyoxypropylene ether triol TMN3050, 190 parts of superfine barium sulfate filler, 5 parts of water-absorbing agent A3, 0.5 parts of organotin catalyst T-12, 2.0 parts Composed of defoamer BYK-530, 2.0 parts of anti-settling agent BYK-306 and 1.0 parts of leveling agent BYK-361N. A and R components are sprayed on the surface of the substrate according to 1:2.5 (volume ratio).

Embodiment 3

[0042] Synthesize 44.5 parts of MDI-50, 44.5 parts of MDI-100, and 11.0 parts of aminoethylaminopropyl polydimethylsiloxane according to the process of the present invention to obtain a prepolymer with an NCO% of 29.8%, which is A components. The R component is composed of 24.7 parts of hydroxyl-terminated cross-linking agent triethanolamine, 150.3 parts of polyoxypropylene ether triol TMN3050, 190 parts of filler superfine barium sulfate, 5 parts of water-absorbing agent A3, 0.5 parts of organotin catalyst T-12, 2.0 parts Composed of defoamer BYK-530, 2.0 parts of anti-settling agent BYK-306 and 1.0 parts of leveling agent BYK-361N. A and R components are sprayed on the surface of the substrate according to 1:2.5 (volume ratio).

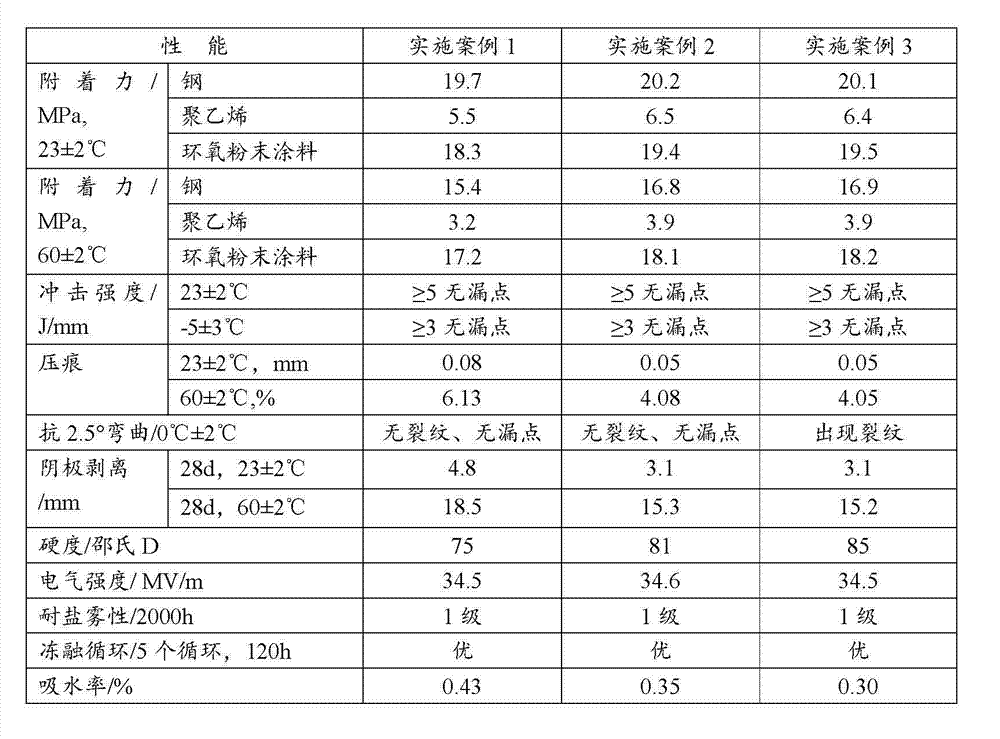

[0043] The performance comparison of implementation cases 1-3 is shown in Table 1.

[0044] Table 1 Performance comparison of implementation cases 1 to 3

[0045]

[0046] It can be seen from Table 1 that with the increase of NCO%, the hardnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com