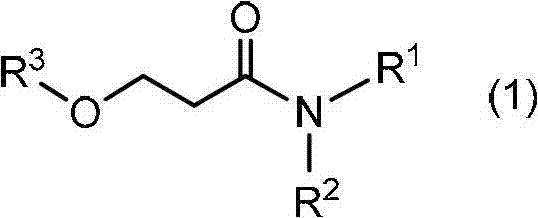

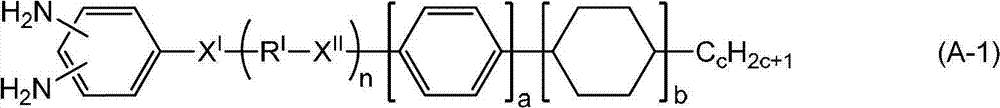

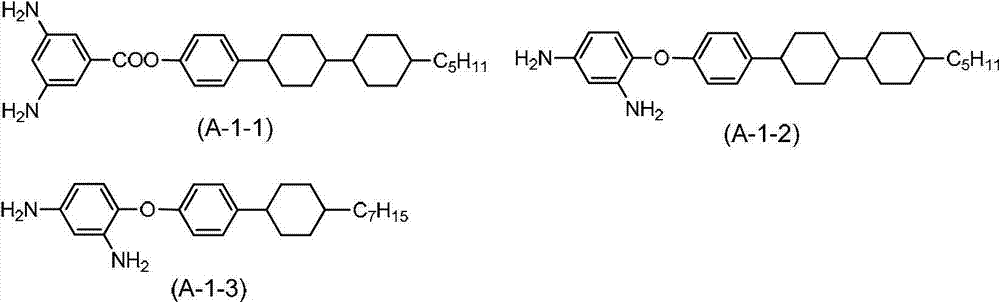

Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display device

A liquid crystal alignment agent and solvent technology, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of printability reduction, achieve good printability, inhibit oxidation degradation, and maintain electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0154] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0155] The solution viscosity of each polymer solution in a synthesis example, and the imidization rate of a polyimide can be measured by the following method.

[0156] Solution Viscosity of Polymer Solution

[0157] The solution viscosity [mPa·s] of the polymer solution can be measured at 25° C. using an E-type rotational viscometer for a solution prepared to have a polymer concentration of 10% by weight using a predetermined solvent.

[0158] Imidation rate of polyimide

[0159] Put the polyimide solution into pure water, dry the obtained precipitate under reduced pressure at room temperature, dissolve it in deuterated dimethyl sulfoxide, and measure it at room temperature with tetramethylsilane as the standard substance 1 H-NMR. according to income 1 From the H-NMR spectrum, the imidation rate [%] was calculated|...

example 1

[0183] In the solution containing 100 parts by weight of the synthesized polyimide (PI-1), 3 parts by weight of IRGANOX1010 (BASF Japan company), NMP as a solvent, ethylene glycol mono-n-butyl ether (BC) and 1,3-dimethyl-2-imidazolidinone (DMI), the solvent composition is NMP: BC: DMI=30 :50:20 (weight ratio), a solution with a solids concentration of 6.5% by weight. This solution was filtered using a filter with a pore diameter of 1 μm, thereby preparing a liquid crystal alignment agent.

example 2~ example 14、 comparative example 1~ comparative example 7

[0185] The liquid crystal alignment agent was prepared respectively by the method similar to the said Example 1 except having changed the polyimide used, antioxidant, and solvent composition as described in following Table 1, respectively.

[0186] Evaluation of printability

[0187] Printability was evaluated about each liquid crystal alignment agent prepared above. Evaluation was performed as follows. First, use a liquid crystal alignment film printing machine (manufactured by Nippon Photo Printing Machine Co., Ltd., Angstromer, model "S40L-532") for each liquid crystal alignment agent of the prepared liquid crystal alignment agent. The dropwise amount was 20 drops (approximately 0.2 g) back and forth, and applied to the transparent electrode surface of a glass substrate with a transparent electrode made of an ITO film. Coating on the substrate was performed 20 times using a new substrate at intervals of 1 minute.

[0188] Next, distribute the liquid crystal alignment age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com