Predictive method of milling machining surface form

A surface topography and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of increasing the number, improving prediction accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

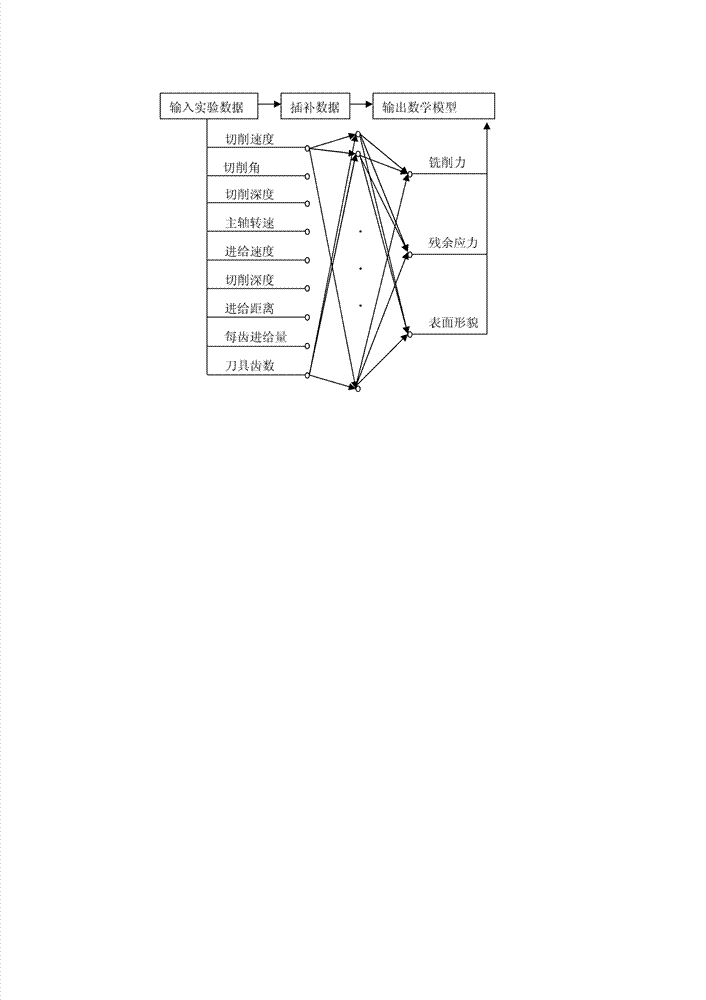

[0011] see figure 1 and figure 2 , The invention provides a method for predicting surface topography in milling.

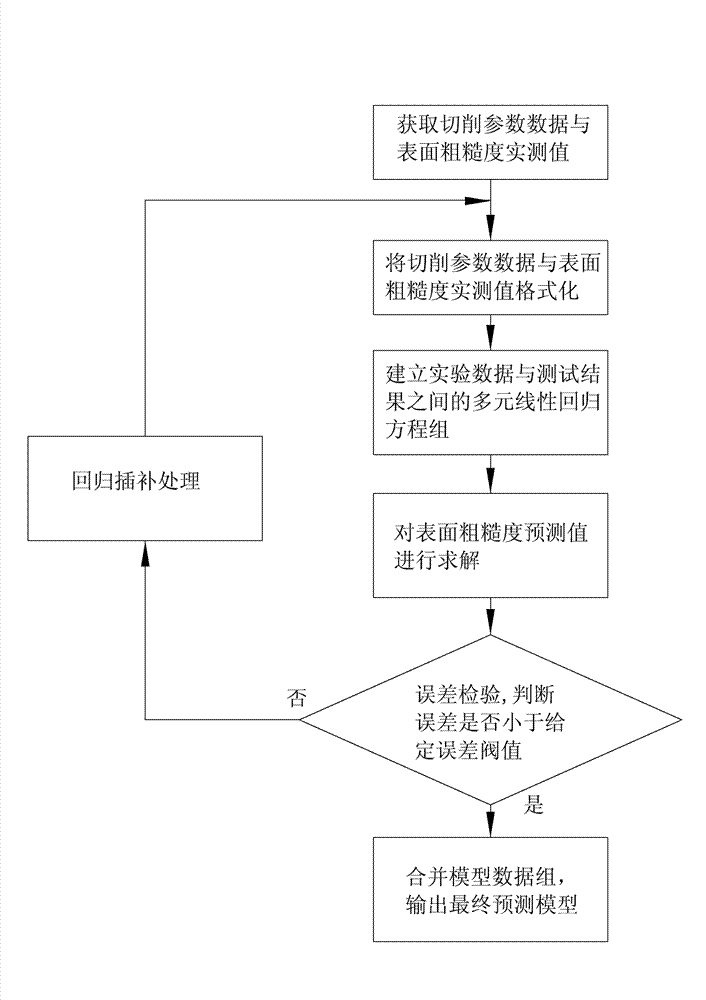

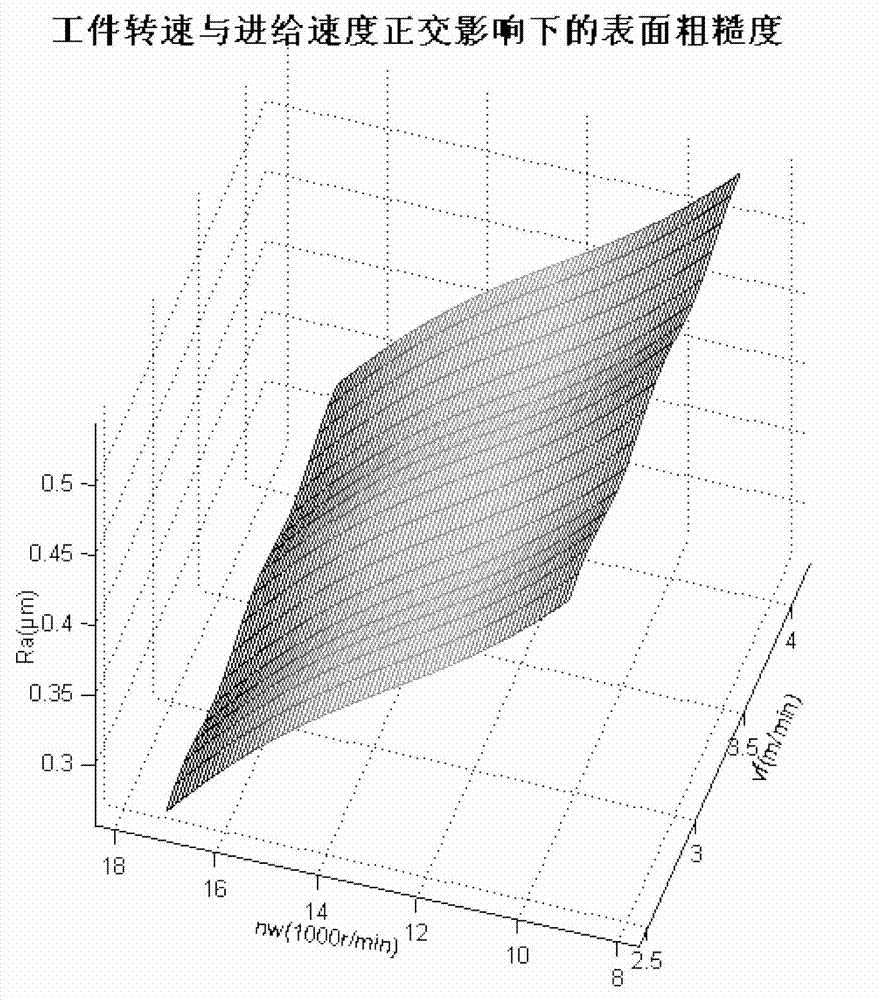

[0012] As shown in the figure, a method for predicting the surface topography of milling processing of the present invention uses the experimental data meter to predict the surface quality parameters after processing by the linear regression method, and combines the ideas and methods of multiple linear regression prediction, and adopts the perfect multivariate nonlinear method provided by Matlab. A toolbox for linear regression and simulation calculations, establishes a multiple linear regression model for surface quality prediction, pre-generates a prediction model after merging data, checks model errors, and then outputs the final shape.

[0013] 1. Surface Topography Prediction Process

[0014] control figure 2 , the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com