Method for hydroprocessing coarse isophthalic acid

A technology of hydrogenation treatment and residence time, which is applied in chemical instruments and methods, preparation of carboxylate salts, preparation of organic compounds, etc., can solve the problems of poor hydrogenation effect of crude IA, and improve the effect of hydrogenation treatment, good technology Effect, the effect of good hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

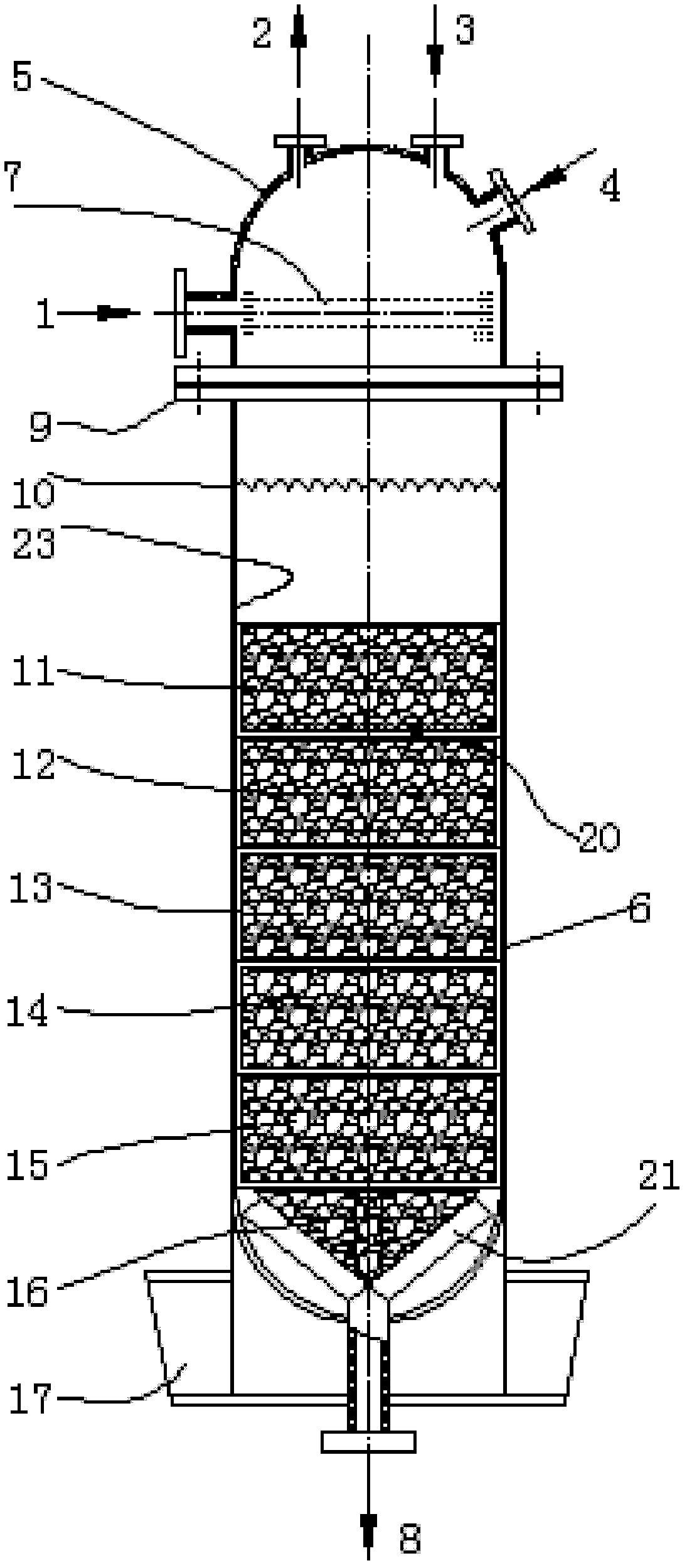

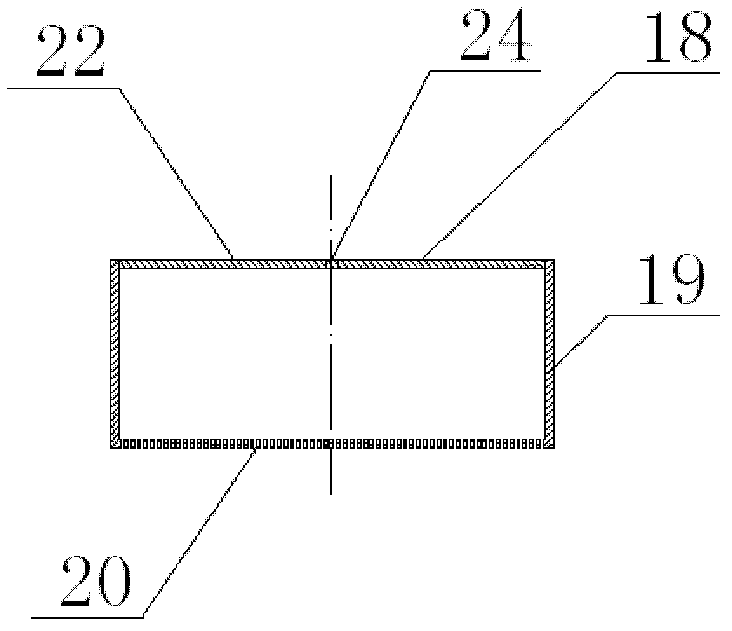

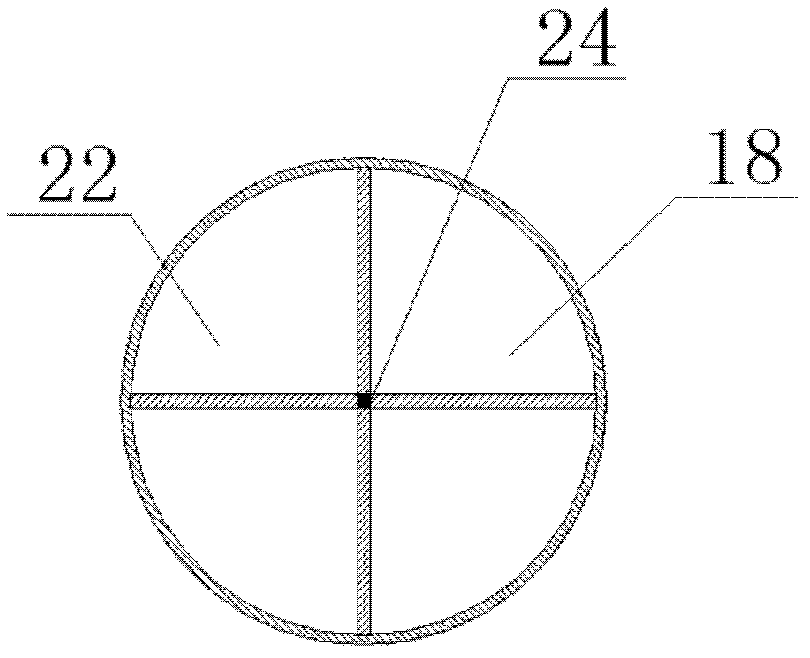

[0029] use as figure 1 The 20.0 L hydrogenation reactor is shown. 5-8 purpose 6000g palladium charcoal catalyst (with coconut shell charcoal as a carrier, in weight percent, palladium content 0.35%) is divided into 6 parts on average, these 6 parts of catalysts are added to catalyst frame 11 through catalyst loading and unloading port 22 respectively ~16, and remove the liquid material inlet 1, emergency discharge port 2, temperature measurement port 3 and gas material inlet 4 related connecting parts, loosen the connecting flange 9 between the reactor top cover 5 and the reactor main body 6 , and remove and open the top cover 5 of the reactor, and then use a long rod with a hook at one end to catch the intersection of the two strips of the matching part 24 of the catalyst frame 16, and hoist the catalyst frame 16 into the reactor At the corresponding position, press down the long rod vertically to make a horizontal displacement away from the position of the intersection, and...

Embodiment 2~8

[0031] The specific implementation process is as in Example 1, only the crude IA feed conditions and hydrogenation reaction conditions are changed, and the crude IA feed conditions, hydrogenation reaction conditions and sample analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com