Marine engine lubrication

An engine, marine technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems that do not involve economy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The invention is illustrated by, but by no means limited to, the following examples.

[0075] components

[0076] Use the following components:

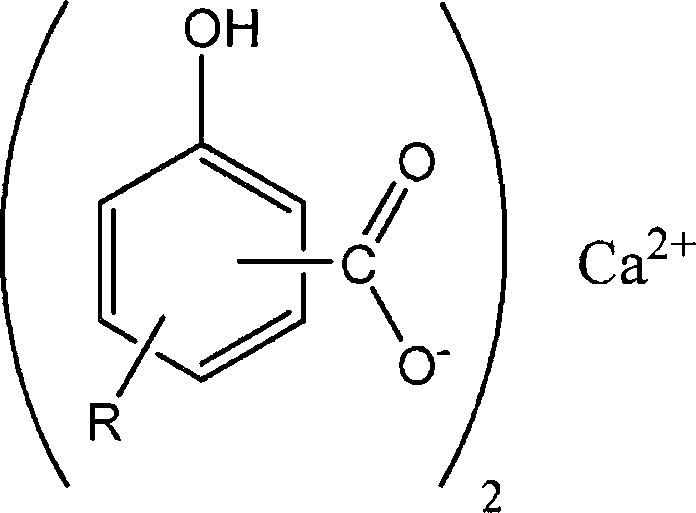

[0077] Component (A): One or more calcium alkyl salicylate detergents having an alkalinity index of 3-6

[0078] Component (B): mixed 2- and 4-(linear C 16 Alkyl)phenol(2:1)

[0079] Base Oil I: Solvent extracted API Group I base oil

[0080] HFO: Heavy Fuel Oil (ISO-F-RMK380)

[0081] lubricant

[0082] The above components are selectively blended to obtain a range of trunk piston marine lubricants. Some lubricants are examples of the invention; others are reference examples for comparison. The lubricant compositions tested when each contained HFO are shown in the table below under the heading "Results".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com